Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Sleepers

Cast Iron Sleepers

Cast Iron Sleepers

Cast iron sleepers are being

extensively used on Indian Railways and about 45% of the track at present

consists of CI sleepers, which may be either pot type or plate type. The main

advantages and disadvantages of CI sleepers over steel trough sleepers are the

following.

Advantages

(a) Less

corrosion

(b) Less

probability of cracking at rail seat

(c) Easy to

manufacture

(d) Higher

scrap value

Disadvantages

(a) Gauge

maintenance is difficult as tie bars get bent

(b) Provides

less lateral stability

(c) Unsuitable

for track-circuited lines

(d) Not very

suitable for mechanical maintenance and/or MSP because of rounded bottom

(e) Susceptible

to breakage

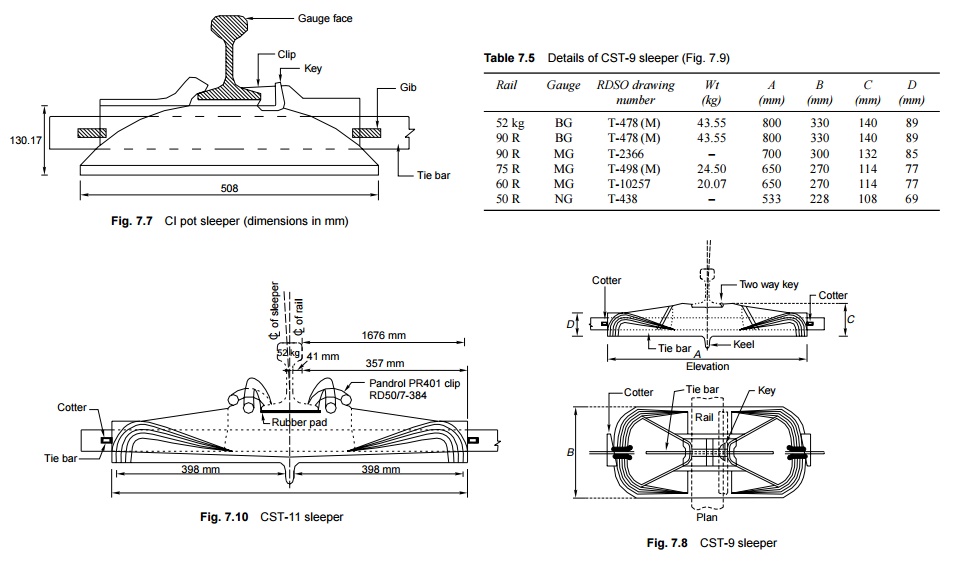

CI pot sleepers

Cast iron pot sleepers (Fig. 7.7) consist of two hollow bowls

or pots of circular or elliptical shape placed inverted on the ballast section.

The two pots are connected by a tie bar with the help of cotters and gibs; the

gauge can be adjusted slightly [± 3 mm (1/8")] by changing their

positions. The rail is placed on top of the pots in a rail seat provided with a

cant of 1 in 20 and is held in position with the help of a key. The pot sleeper

suffers from the drawback that it cannot be used on curves sharper than 4 o on

BG. Most of the fittings are hidden and their inspection and maintenance is

quite difficult. These sleepers have become obsolete now and are not being

procured by the Indian Railways any more.

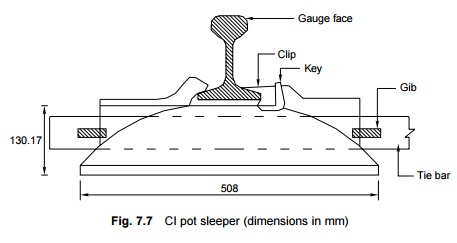

CST-9 sleepers

The CST-9 sleeper is a standard sleeper and is being most

extensively used on Indian Railways (IR). It is called CST-9 (Central Standard

Trial-9) (Fig. 7.8) because it is the ninth of the series produced by the

Central Standard Office. The sleeper is a combination of pot, plate, and box

sleepers. It consists of two triangular inverted pots on either side of the

rail seat, a central plate with a projected keel, and a box on top of the

plate. The two CI plates are connected by a tie bar with the help of four

cotters. The rails are held to the sleeper by two-way keys provided at each

rail seat on the side of the gauge face. The gauge is adjusted to a value of ±

5 mm by altering the relative positions of the four cotters.

The rail seat of a CST-9 sleeper

is 115 mm wide along the length, and this narrow bearing tends to reduce the

rocking of the sleeper under the wave motion of the rail. The sleeper is

designed to provide a firm support to the rail and provides fairly good lateral

and longitudinal stability to the rails. The dimensions of CST sleepers in use

on IR are given in Table 7.5. The sleeper provides a bearing area approximately

equal to the effective bearing area of a standard BG wooden sleeper, i.e., 5

sq. ft, for both the plates. CST-9 plates are also available with reverse jaws

(T-443 type) to serve as an anti-sabotage measure; a few of these are provided

in each rail length. Normally, three reverse jaw CST-9 sleepers are provided

per rail to serve anti-sabotage purposes. The weight of a CST-9 sleeper

assembly along with fastenings for BG is 102 kg and for MG is 58 kg.

The CST-9 sleeper is one of the most popular sleepers on

Indian Railways at present. The sleeper has, however, certain limitations when

combined with the modern track as mentioned in the following.

(a) As the

sleeper does not have a flat bottom, it is not quite suitable for MSP and

mechanical maintenance with tie tamers.

(b) The

suitability of a CST-9 sleeper on LWRs, particularly on the breathing lengths,

is doubtful because of rigid fastenings and the inability of the fastenings to

hold the rail with a constant toe load.

(c) The rail

seat wears out quickly causing the keys to come loose.

(d) The

sleeper has only limited longitudinal and lateral strength to hold LWRs,

particularly in the breathing length.

(e) Due to

the use of less metal under rail seat, the shocks and vibrations are directly

transmitted to the ballast, resulting in poor retention of packing (loose

packing) and hence an increased frequency of attention.

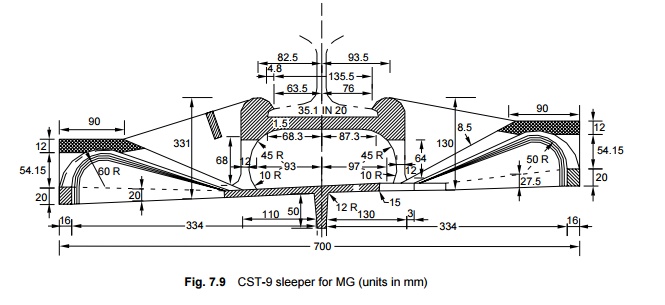

CST-9 sleeper for MG

A new design of the CST-9 sleeper

has recently been developed by Indian Railways for 90 R rails on MG lines as

shown in Fig. 7.9.

CST-10 sleepers

The CST-10 sleeper is an

improvement on the design of the CST-9 sleeper to suit the requirements of a

modern track. The basic design feature of this sleeper is the same as that of a

CST-9 sleeper except the following improvements.

(a) The rail

is held with clips and double-coil spring washers instead of a fixed lug and

key.

(b) An

insulating liner is provided between the rail and the sleeper.

(c) A rubber

pad is provided below the rail seat.

A CST-10 sleeper gives certain

amount of elasticity to the track by virtue of its double-coil spring washer.

The sleeper, however, has the limitation that it cannot be used with elastic

fastenings.

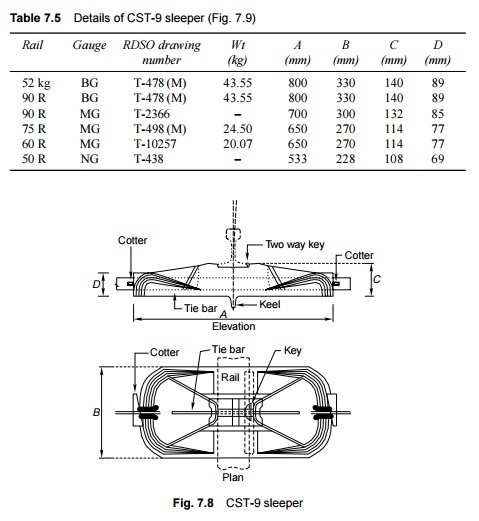

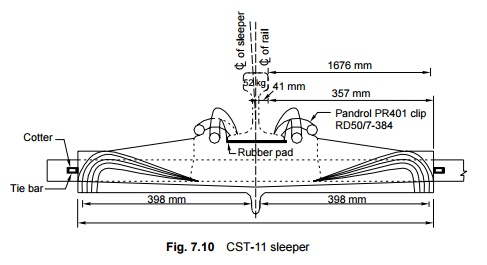

CST-11 sleepers

The CST-11 sleeper is an

improvement over the CST-10 sleeper. A special shoulder is provided to

accommodate the Pandrol clip instead of clips and double-coil spring washers.

An elastic rubber pad is provided between the sleeper and the rail seat instead

of the rail resting directly on the sleeper. The CST-11 sleeper has the

potential of being used on the modern track. The sleeper, however, is still in

the experimental stage and the results are not very encouraging at present. Its

design details are shown in Fig. 7.10.

CST-12 sleepers

CST-12 sleepers are designed to

suit the IRN-202 clip, instead of the Pandrol clip. In this case the casting is

quite complicated due to the shape of the clip. No firm has undertaken the

manufacture of this sleeper as yet.

CST-13 sleepers

The purpose of the CST-13 sleeper is to use the existing CST-9

sleeper with certain additions and alternations made in the local workshop. It

consists of the CST-9.

plate with the rubber pad under

the rail and an additional rubber head to fill the gap occupied by the key. The

rail is fastened to the sleeper by a sigma clip, similar to the 'fist

fastening' used on Swedish Railways. To reduce the cost of the sleeper, the

inner cotter is dispensed with. No adjustment of gauge is possible in this

sleeper. The CST-13 sleeper is still under trial.

Related Topics