Chapter: Civil : Construction Materials: Lime, Cement, Aggregates, Mortar

Soundness Test (IS: 2386 Part V)

Soundness Test (IS: 2386 Part V)

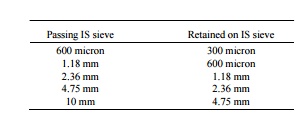

The

sample of fine aggregate for the test is passed through 10-mm IS sieve and

should be of such size that it yields not less than 100 g of each of the sizes

as below.

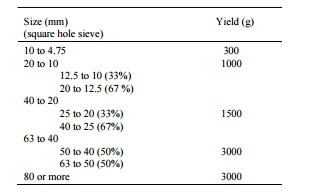

From the sample of coarse

aggregate, sizes finer than 4.75 mm are removed and the size of sample for

different sizes should be as follows.

Note: All-in-aggregate should be

separated in two major fractions, finer than 4.75 mm and coarser than 4.75 mm,

and tested.

In case of fine aggregate, these

are thoroughly washed on a 300 micron IS sieve and dried to constant weight at

105 to 110 o C and separated into different sizes by the set of sieves listed

earlier to yield at least 100g each. The coarse aggregate sample are washed

thoroughly and dried to constant weight at 105 to 110 o C and separated into

different sizes. Particles coarser than the 20 mm IS sieve are counted.

The aggregate sample is immersed

for 16 to 18 hours in the prepared solution of either sodium sulphate or

magnesium sulphate solution. The sample is maintained at 27 ± 1 o C. The

aggregate sample is then removed from the solution and drained for 15 ± 5

minutes, placed in drying oven at 105 -110 o C and dried to constant weight. The

sample is allowed to cool to room temperature. The process of immersion and

drying is repeated for as many number of cycles as agreed to between the

purchaser and vendor. The sample is then examined for quantitative and

qualitative examination.

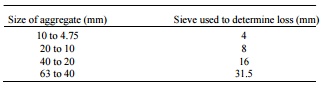

Quantitative

examination: After the completion of final cycle the cooled sample is washed

free from the sodium sulphate or magnesium sulphate with barium chloride. Each

sample is dried to constant weight at 105 - 110 o C and weighed. Fine aggregate

are sieved over the same sieve on which it was retained before the test, and

coarse aggregate over the following sieves.

Qualitative

examination: Frations of samples coarser than 20 mm are examined qualitatively

for each immersion as well as at the completion of the test. The effects

observed may be classed as disintegration, splitting, crumbling, cracking,

flaking, etc.

Related Topics