Chapter: Civil : Construction Materials: Lime, Cement, Aggregates, Mortar

Aggregate Abrasion Value Test (IS: 2386 (Part IV))

Aggregate Abrasion Value Test (IS:

2386 (Part IV))

The abrasion value

of coarse aggregate may be determined by either Deval Machine or by Los Angeles

machine.

Using Deval Machine

Abrasive Charge: The abrasive charge consists of

6 cast iron or steel spheres approximately 48 mm in diameter, each weighing

between 390 and 445 g. An abrasive charge of 6 spheres weighing 2500 ± 10 g is

used with each test sample.

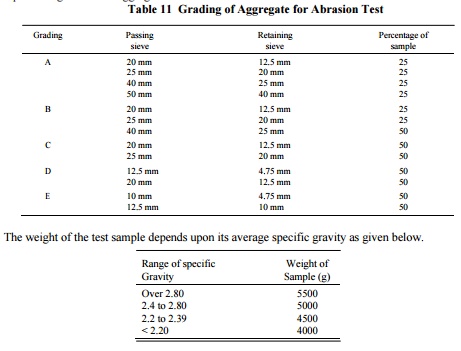

The test sample

consists of dry coarse aggregate made up of percentages of the various sizes

conforming to one of the gradings shown in Table 6.7. The grading used should

be that most nearly representing the coarse aggregate furnished for the work.

Procedure: The test sample and

the abrasive charge are placed in the Deval abrasion testing machine and the

machine is rotated for 10000 revolutions at a speed of 30 to 33 rev/min. At the

completion of the test, the material is removed from machine and sieved on a

1.70 mm sieve. The material retained on the sieve is washed, dried and

accurately weighed to the nearest gram.

The loss by abrasion is

considered as the difference between the original weight of the sample and the

weight of the material retained on the 1.70 mm sieve, expressed as percentage

of the original weight of the test sample.

In case of crushed gravel, the

percentage by weight of crushed fragments is determined, and the permissible

percentage or wear is calculated as:

W = AL (100

A)L / 100

Where W =

permissible percentage of wear

A = percentage of

uncrushed fragments

L= maximum percentage of wear

permitted by the specifications for gravel consisting entirely of uncrushed

fragments

100 - A = percentage of crushed

fragments

L = maximum

percentage of wear permitted by the specifications for gravel consisting

entirely of crushed fragments

Using Los Angeles Machine

Abrasive Charge: The abrasive

charge consists of cast iron spheres or steel spheres approximately 48 mm in

diameter and each weighing between 390 and 445 g.

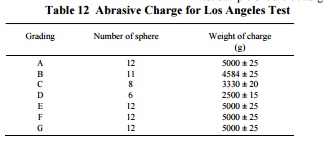

The

abrasive charge, depending upon the grading of the test sample should be as

given in Table 12.

The test sample consists of clean

aggregate dried in an oven at 105 -110 o C to substantially constant weight.

Note: It is recognized that

different specification limits may be required for gradings E, F and G than for

A, B, C and D. It is urged that investigations be conducted to determine the

relationship, if any, which exists between results for these coarse gradings

using the 10000 g samples and the finer ones using the 5000 g samples.

The test sample and the abrasive

charge is placed in the Los Angeles abrasion testing machine and the machine is

rotated at a speed of 20 to 33 rev/min. For gradings A, B, C and D, the machine

is rotated for 500 revolutions; for gradings E, F and G, it is rotated for 1000

revolutions. The machine is so driven and so counter-balanced as to maintain a

substantially uniform peripheral speed. If an angle is used as the shelf, the

machine is rotated in such a direction that the charge is caught on the outside

surface of the angle. At the completion of the test, the material is discharged

from the machine and a preliminary separation of the sample made on a sieve

coarser than the 1.70 mm. The finer portion is then sieved on a 1.70 mm

sieve.The material coarser than the 1.70 mm sieve is washed, dried in an oven

at 105 -110 o C to a substantially constant weight, and accurately weighed to the

nearest gram. The difference between the original and the final weights of the

test sample expressed as a percentage of the original weight of the test sample

gives the percentage of wear.

Related Topics