Chapter: Civil : Construction Materials: Lime, Cement, Aggregates, Mortar

Determination of Cement Strength

Determination of Cement Strength

Cement hydrates when water is

added to it and cohesion and solidity is exhibited. It binds together the

aggregates by adhesion. The strength of mortar and concrete depends upon the

type and nature of cement. So, it should develop a minimum specified strength if

it is to be used in structures. Cement is tested for compressive and tensile

strengths.

Conditions Affecting Strength:

Cement is very strong at early ages if a high lime or high alumina content is

there. Gypsum and Plaster of Paris in small percentages also tend to increase

the strength slightly, but when present in quantities larger then 3 per cent,

these substances provide variable effects. The effect of the clinker compounds

on strength have already been discussed. In addition to the effect of composition,

the strength of cement is greatly influenced by the degree of burning, the

fineness of grinding, and the aeration it receives subsequent to final

grinding. An underburnt cement is likely to be deficient in strength.

Compressive Strength: Compressive

strength is the basic data required for mix design. By this test, the quality

and the quantity of concrete can be cotrolled and the degree of adulteration

can be checked.

The test specimens are 70.6 mm

cubes having face area of about 5000 sq. mm. Large size specimen cubes cannot

be made since cement shrinks and cracks may develop. The temperature of water

and test room should be 27 o ± 2 o C. A mixture of cement and standard sand in the

proportion 1:3 by weight is mixed dry with a trowel for one minute and then

with water until the mixture is of uniform colour. Three specimen cubes are

prepared. The material for each cube is mixed separately. The quantities of

cement, standard sand and water are 185 g, 555 g and (P/4) + 3.5, respectively

where P = percentage of water required to produce a paste of standard

consistency. The mould is filled completely with the cement paste and is placed

on the vibration table. Vibrations are imparted for about 2 minutes at a speed

of 12000±4 00 per minute.

The cubes are then removed from

the moulds and submerged in clean fresh water and are taken out just prior to

testing in a compression testing machine. Compressive strength is taken to be

the average of the results of the three cubes. The load is applied starting

from zero at a rate of 35 N/sq mm/minute. The compressive strength is

calculated from the crushing load divided by the average area over which the

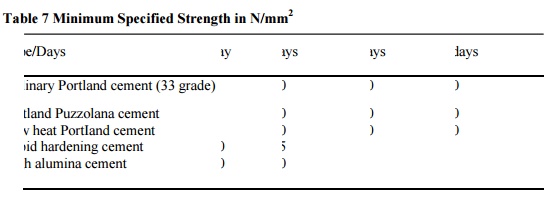

load is applied.The result is expressed in N/mm2. The minimum

specified strength for some of the cements is given in Table 5.4.

Table 7

Minimum Specified Strength in N/mm2

Tensile Strength: The

tensile strength may be determined by Briquette test method or by split tensile

strength test.

Importance: The

tensile strength of cement affords quicker indications of defects in the cement

than any other test. Also, the test is more conveniently made than the

compressive strength test. Moreover, since the flexural strength, is directly

related to the tensile strength this test is ideally fitted to give information

both with regard to tensile and compressive strengths when the supply for

material testing is small.

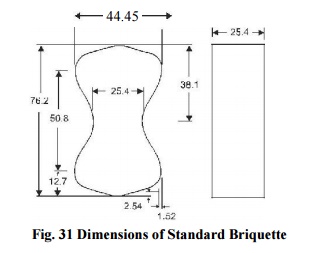

Briquette Method: A mixture

of cement and sand is gauged in the proportion of 1:3 by weight. The percentage

of water to be used is calculated from the formula (P/5) + 2.5, where P =

percentage of water required to produce a paste of standard consistency. The

temperature of the water and the test room should be 27 o ± 2 o C. The mix is

filled in the moulds of the shape shown in Fig. 5.11.

After

filling the mould, an additional heap of mix is placed on the mould and is

pushed down with the standard spatula, until the mixture is level with the top

of the mould. This operation is repeated on the other side of the mould also.

The briquettes in the mould are finished by smoothing the surface with the

blade of a trowel. They are then kept for 24 hours at a temperature of 27 o ±

2 o C and in an atmosphere having 90 per cent humidity. The briquettes are then

kept in clean fresh water and are taken out before testing. Six briquettes are

tested and the average tensile strength is calculated. Load is applied steadily

and uniformly, starting from zero and increasing at the rate of 0.7 N/sq mm of

section in 12 seconds.

Ordinary Portland cement should

have a tensile strength of not less than 2.0 N/mm2 after 3 days and

not less than 2.5 N/mm2 after 7 days.

Notes: (i) In the tension test of cement the load

on the briquette should be applied centrally. Since briquettes become brittle

with age, the effect of slight eccentricity or any torsional strain is

pronounced in long-time tests.

(ii) The strength increases when the loading rate

is increased from that specified.

Related Topics