Chapter: Civil : Construction Materials: Lime, Cement, Aggregates, Mortar

Manufacture Of Cement

Manufacture Of Cement

Calcareous and argillaceous raw

materials are used in the manufacture of Portland cement. The calcareous

materials used are cement rock, limestone, marl, chalk and marine shell. The

argillaceous materials consist of silicates of alumina in the form of clay, shale,

slate and blast furnace slag.

From the

above materials, others like lime, silica, alumina, iron oxide and small

quantities of other chemicals are obtained. Cement can be manufactured either

by dry process or wet process.

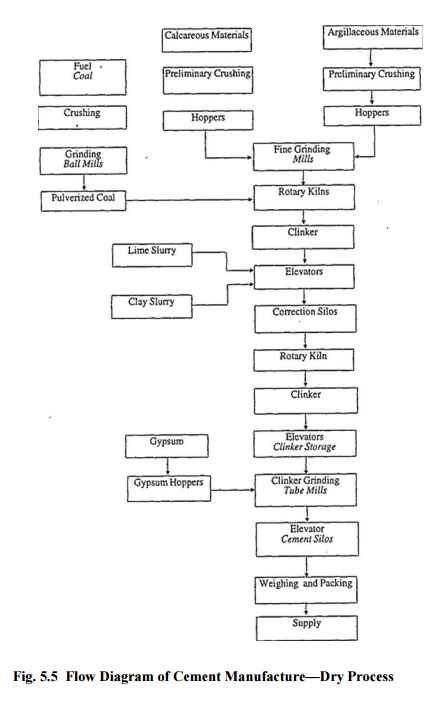

Dry

Process

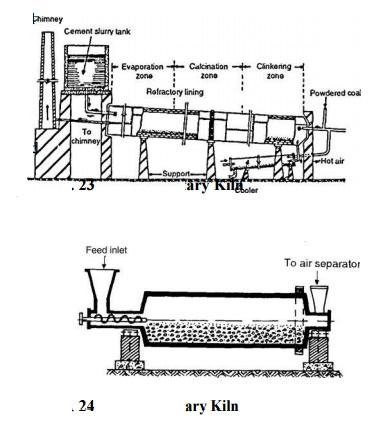

The dry

process is adopted when the raw materials are quite hard. The process is slow

and the product is costly. Limestone and clay are ground to fine powder

separately and are mixed. Water is added to make a thick paste. The cakes of

this paste, which contain about 14 per cent of moisture, are dried and are

charged into rotary kiln (Fig. 23). The product obtained after calcination in

rotary kiln is called clinker. The clinker is obtained as a result of incipient

fusion and sintering at a temperature of about 1400 o - 1500 o C. Because ferric

oxide has lower melting point than the other oxides, it acts as a flux. Aeration

of cement clinker, which is commonly practised to slake free lime, also causes

an absorption of some moisture and carbon

dioxide. Absorption of moisture tends to decrease the setting

whereas that of carbon dioxide accelerates setting. The clinker is cooled

rapidly to preserve the metastable compounds and their solid solutions -

dispersion of one solid in another - which

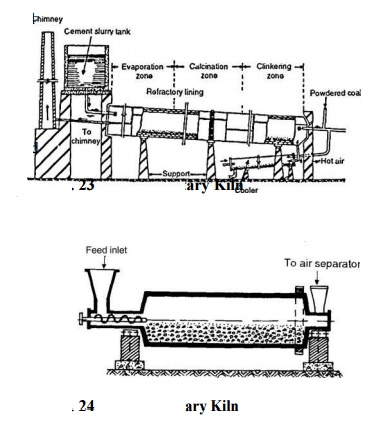

are made as the clinker is heated. Clinker is then cooled and ground in tube

mills (Fig. 24),

where

2-3% of gypsum is added. Generally, cement is stored in bags of 50 kg. A flow

diagram of dry process is shown in Fig. 25. The purpose of adding gypsum is to

coat the cement particles by interfering with the process of hydration of the

cement particles. This retards the setting of cement.

Wet

Process

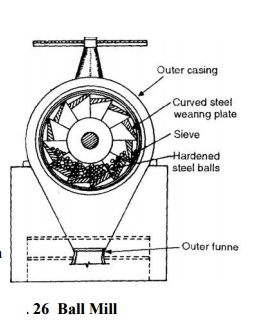

operations in the wet process of cement manufacture

mixing, burning and grinding. The crushed raw erials are fed into ball mill

(Fig. 26) and a little water dded. On operating the ball mill, the steel balls

in it verize the raw materials which form a slurry with er. This slurry is

passed to silos (storage tanks), where proportioning of the compounds is

adjusted to ensure red chemical composition. The corrected slurry ing about 40

per cent moisture content, is then fed rotary kiln (Fig. 24) where it loses

moisture and ms into lumps or nodules. These are finally burned at 0-1600 o C.

The nodules change to clinker at this

perature. Clinker is cooled and then ground in tube s. While grinding the clinker,

about 3 per cent gypsum dded. The cement is then stored in silos from where

supplied. A flow diagram of manufacturing cement wet process is shown in Fig.

27.

Comparison

of Wet and Dry Process: The chief advantages of the wet process are

the low cost of excavating and grinding raw materials, the accurate

control of composition and homogeneity of the slurry, and the economical

utilization of fuel through the elimination of separated drying operations. On

the other hand the longer kilns, essential in the wet process, cost more and

are less responsive to a variable clinker demand than the short kilns which can

be used in the dry process.

Related Topics