Chapter: Special Electrical Machines : Stepping Motor

Single Stack Variable Reluctance Stepper Motor: Construction and Principle of Operation

SINGLE STACK VARIABLE RELUCTANCE

STEPPER MOTOR

1. Construction:

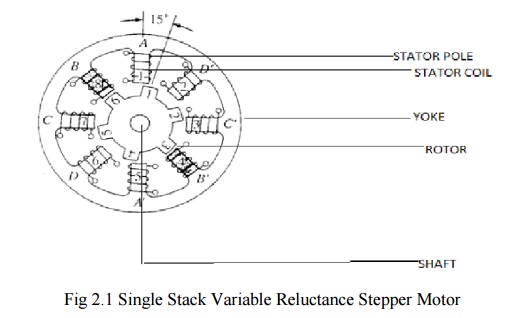

The VR

stepper motor characterized by the fact there is no permanent magnet either on

the rotor or the stator. The construction of a 3-phase VR stepper motor with 6

poles on the stator and 4-pole on the rotor as shown.

The

Stator is made up of silicon steel stampings with inward projected even or odd

number of poles or teeth. Each and every stator poles carries a field coil an

exciting coil. In case of even number of poles the exciting coils of opposite

poles are connected in series. The two coils are connected such that their MMF

gets added .the combination of two coils is known as phase winding.

The rotor

is also made up of silicon steel stampings with outward projected poles and it

does not have any electrical windings. The number of rotor poles should be

different from that of stators in order to have self-starting capability and bi

direction. The width of rotor teeth should be same as stator teeth. Solid

silicon steel rotors are extensively employed. Both the stator and rotor

materials must have lowering a high magnetic flux to pass through them even if

a low magneto motive force is applied.

2. Electrical Connection

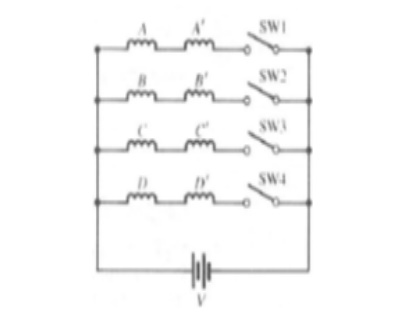

Electrical

connection of VR stepper as shown fig. Coil A and A‘ are connected in series to

form a phase winding. This phase winding is connected to a DC source with the

help of semiconductor switch S1.Similary B and B‘ and C and C‘ are connected to

the same source through semiconductor switches S2 and S3 respectively. The

motor has 3 –phases a, b and c.

v a phase

consist of A and A‘ Coils

v b phase

consist of B and B‘ Coils

v c phase

consist of C and C‘ Coils

3. Principle of Operation

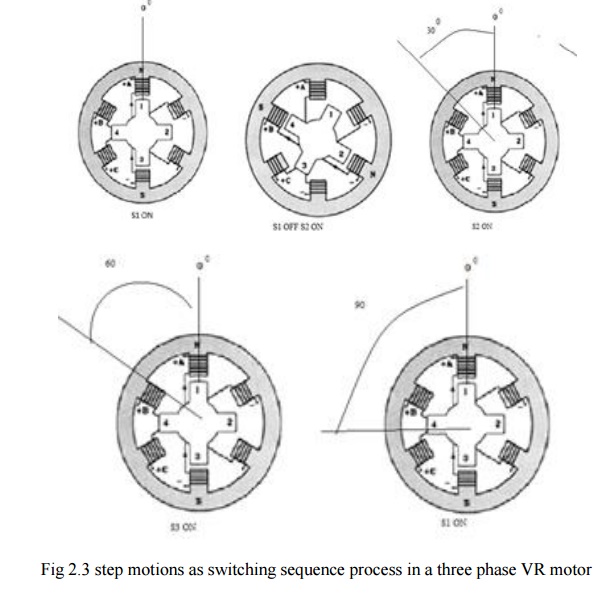

It works

on the principle of variable reluctance. The principle of operation of VR

stepper motor explained by referring fig.

(a).Mode 1 : One phase ON or full step operation

In this

mode of operation of stepper motor only one phase is energized at any time. If

current is applied to the coils of phase ‗a‘ (or) phase ‗a‘ is excited, the

reluctance torque causes the rotor to run until aligns with the axis of phase

a. The axis of rotor poles 1 and 3 are in alignment with the axis of stator

poles ‗A‘ and ‗A‘‘. Then angle θ = 0° the magnetic reluctance is minimized and

this state provides a rest or equilibrium position to the rotor and rotor

cannot move until phase ‗a‘ is energized.

Next

phase b is energized by turning on the semiconductor switch S2 and phase ‗a‘ is

de –energized by turning off S1.Then the rotor poles 1 and 3 and 2 and 4

experience torques in opposite direction. When the rotor and stator teeth are

out of alignment in the excited phase the magnetic reluctance is large. The

torque experienced by 1 and 3 are in clockwise direction and that of 2 and 4 is

in counter clockwise direction. The latter is more than the former. As a result

the rotor makes an angular displacement of 30° in counterclockwise direction so

that B and B‘ and 2 and 4 in alignment. The phases are excited in sequence a, b

and c the rotor turns with a step of 30° in counter clockwise direction. The

direction of rotation can be reversed by reversing the switching sequence in

which are energized and is independent of the direction of currents through the

phase winding.

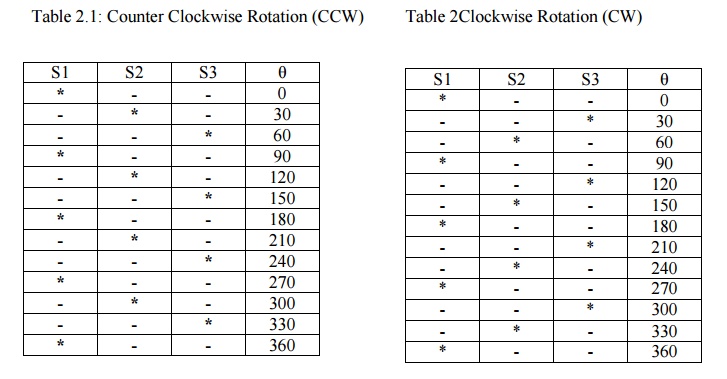

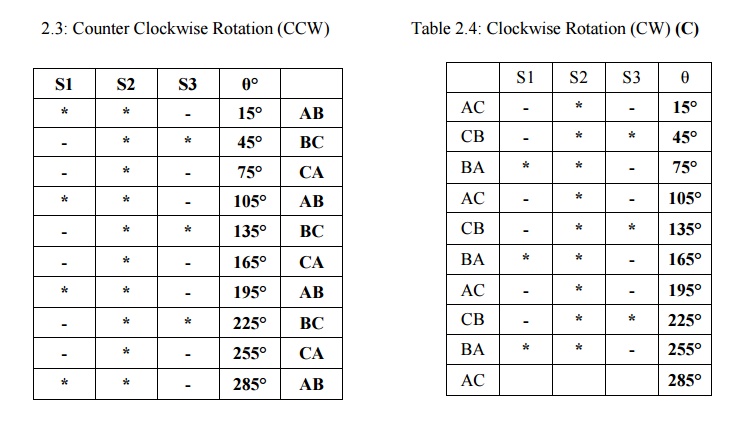

The truth table for mode I operation in counter and clockwise directions are given in the table

Table

2.1: Counter Clockwise Rotation (CCW) Table

2Clockwise Rotation (CW)

(b).Mode II: Two Phase on Mode

In this

mode two stator phases are excited simultaneously. When phases a and b are

energized together, the rotor experiences torque from both phases and comes to

rest in a point mid-way between the two adjacent full step position. If the

phases b and c are excited, the rotor occupies a position such that angle

between AA‘ axis of stator and 1-3 axis of rotor is equal to 45°.To reverse the

direction of rotation switching sequence is changed a and b,a and c etc. The

main advantage of this type of operation is that torque developed by the

stepper motor is more than that due to single phase ON mode of operation.

The truth

table for mode II operation in counter clockwise and clockwise directions is

given in a tableTable

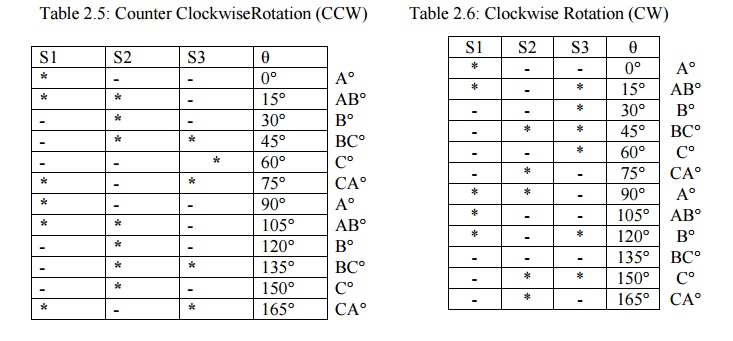

Mode III: Half step Mode

In this type

of mode of operation on phase is ON for some duration and two phases are ON

during some other duration. The step angle can be reduced from 30° to 15° by

exciting phase sequence a, a+b, b,b+c, c etc. The technique of shifting

excitation from one phase to another from a to b with an intermediate step of

a+b is known as half step and is used to realize smaller steps continuous half

stepping produces smoother shaft rotation.

The truth

table for mode III operation in counter and clockwise directions are given in

the table

Related Topics