Chapter: Special Electrical Machines : Stepping Motor

Multistack Variable Reluctance Stepper Motor

MULTISTACK VARIABLE RELUCTANCE

STEPPER MOTOR

These are

used to obtain smaller step sizes, typically in the range of 2° to 15°.

Although three stacks are common a multistack motor may employ as many as seven

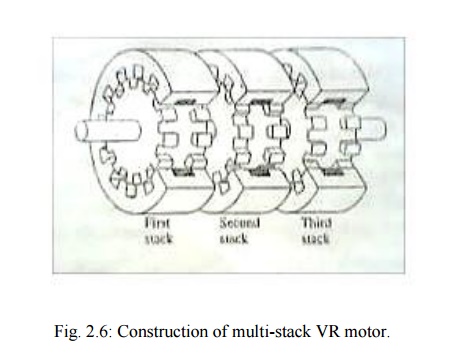

stacks. This type is also known as the cascade type. A cutaway view of a three

stack motor is shown in fig. 2.6.

A

multistack (or m-stack) variable reluctance stepper motor can be considered to

be made up of ‘m‘ identical single stack variable reluctance motors with their

rotors mounted on a single shaft. The stators and rotors have the same number

of poles (or teeth) and therefore same pole (tooth) pitch. For a m0stack motor,

the stator poles (or teeth) in all m stacks are aligned, but the rotor poles

(teeth) are displaced by 1/m of the pole pitch angle from one another. All the

stator pole windings in a given stack are exited simultaneously and, therefore

the stator winding of each stack forms one phase. Thus the motor has the same

number of phases as number of stacks.

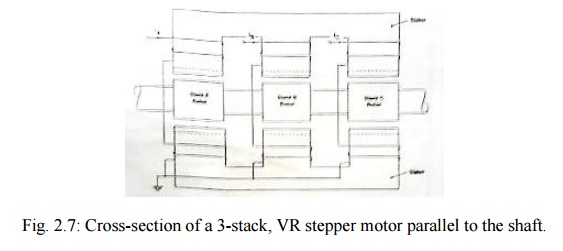

Figure

2.7 shows the cross section of a three stack (3-phase) motor parallel to the

shaft. In each stack, stator and rotors have 12 poles (teeth). For a 12 pole

rotor, pole pitch is 30° and therefore, the rotor poles (teeth) are displaced

from each other by 1/3rd of the pole pitch or 10°. The stator teeth in each

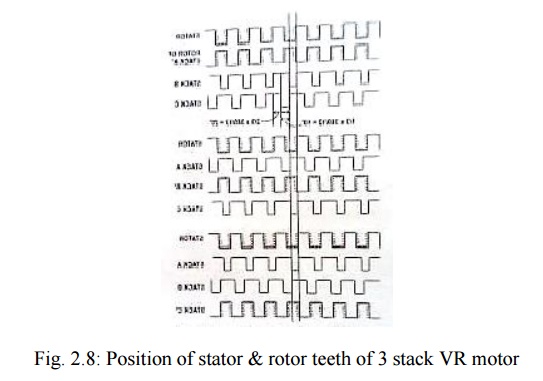

stack are aligned. When the phase winding A is excited rotor teeth of stack A

are aligned with the stator teeth as shown in fig. 2.8.

When

phase A is de-energized and phase B is excited the rotor teeth of stack B are

aligned with stator teeth. The new alignment is made by the rotor movement of

10° in the anticlockwise direction. Thus the motor moves one step (equal to ½

pole pitch) due to change of excitation from stack A to stack B

Next

phase B is de-energized and phase C is excited. The rotor moves by another step

1/3rd of pole pitch in the anticlockwise direction. Another change of

excitation from stack C to stack A will once more align the stator and rotor

teeth in stack A. however during this process (A → B → C → A) the rotor has

moved one rotor tooth pitch.

Let Nr be

the number of rotor teeth and ‗m‘ the number of stacks or phases, then

Tooth

pitch Tp= 360/Nr ……………… (2.1)

Step

Angle α= 360°/mNr ………………. (2.2)

Related Topics