Chapter: Mechanical : Robotics : Fundamentals of Robot

Robotics Co-ordinate System

Co-ordinate System

A coordinate system defines a plane or space by axes

from a fixed point called the origin. Robot targets and positions are located

by measurements along the axes of coordinate systems. A robot uses several

coordinate systems, each suitable for specific types of jogging or programming.

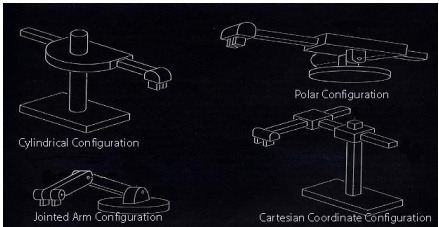

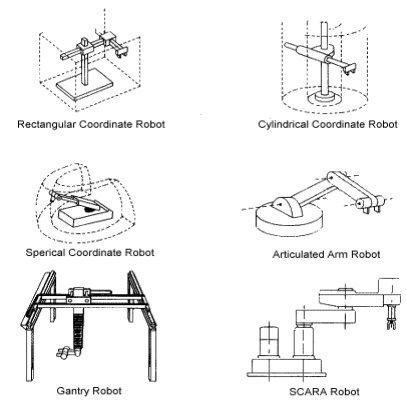

The Robots are mostly divided into

four major configurations based on their appearances, sizes, etc. such as:

·Cylindrical

Configuration,

·Polar

Configuration,

·Jointed

Arm Configuration, and

·Cartesian

Co-ordinate Configuration.

Cylindrical

Configuration:

This kind of robots incorporates a

slide in the horizontal position and a column in the vertical position. It also

includes a robot arm at the end of the slide. Here, the slide is capable of

moving in up & down motion with the help of the column. In addition, it can

reach the work space in a rotary movement as like a cylinder.

Example:

GMF Model M1A Robot.

Advantages:

·

Increased rigidity, and

· Capacity of carrying high payloads. Disadvantages:

·

Floor space required is

more, and

·

Less work volume.

Polar Configuration:

The polar configuration robots will possess an arm, which can

move up and down. It comprises of a rotational base along with a pivot. It has

one linear & two rotary joints that allows the robot to operate in a

spherical work volume. It is also stated as Spherical Coordinate Robots.

Example:

Unimate 2000 Series Robot.

Advantages:Long reach capability in the horizontal position.

Disadvantages:

·Vertical reach is low.

Jointed Arm

Configuration:

The arm in these configuration robots

looks almost like a human arm. It gets three rotary joints and three wrist

axes, which form into six degrees of freedoms. As a result, it has the capability

to be controlled at any adjustments in the work space. These types of robots

are used for performing several operations like spray painting, spot

welding, arc welding, and more.

Example:

Cincinnati Milacron T3 776 Robot

Advantages:

·

Increased flexibility,

·

Huge work volume, and

· Quick operation. Disadvantages:

·

Very expensive,

·

Difficult operating

procedures, and

·

Plenty of components.

Cartesian Co-ordinate

configuration:

These robots are also called as XYZ

robots, because it is equipped with three rotary joints for assembling XYZ

axes. The robots will process in a rectangular work space by means of this

three joints movement. It is capable of carrying high payloads with the help of

its rigid structure. It is mainly integrated in some functions like pick and

place, material handling, loading and unloading, and so on. Additionally, this

configuration adds a name of Gantry Robot.

Example:

IBM 7565 Robot.

Advantages:

·

Highly accurate &

speed,

·

Fewer cost,

·

Simple operating

procedures, and

·

High payloads.

Disadvantages:

·

Less work envelope, and

·

Reduced flexibility.

Work Envelop

It is the shape created when a manipulator

reaches forward, backward, up and down.

These

distances are determined by the length of a robot's arm

and the design of its axes. Each axis contributes its own range of motion.

A robot can only

perform within the confines of this work envelope.

Still, many of the robots

are designed with considerable flexibility. Some have the ability to reach

behind themselves. Gantry robots defy traditional constraints of work

envelopes. They move along track systems to create large work spaces.

Technical Features of

an Industrial Robot

The technical features of an industrial robot

determine its efficiency and effectiveness at performing a given task. The

following are some of the most important among these technical features.

Related Topics