Chapter: Mechanical : Computer Aided Design : Fundamentals of Computer Graphics

Fundamentals of Computer Graphics

FUNDAMENTALS OF COMPUTER GRAPHICS

Introduction of CAD

In the mid of 1970s, as computer aided

design starts to offer more potential than just a skill to replicate manual

drafting with electronic drafting, the cost gain for companies to switch to CAD

became obvious. The benefit of CAD methods over manual drafting are the

capabilities one often takes for established from computer systems; automated

creation of Bill of Material, interference checking, auto layout in integrated circuits.

Product

cycle

Product cycle integrate processes,

people, data, and business and gives a product information for industries and

their extended activity. Product cycle is the process of managing the entire

lifecycle of a product from starting, through design and manufacture, to repair

and removal of manufactured products.

Product cycle methods assist association

in managing with the rising difficulty and engineering challenges of developing

new products for the worldwide competitive markets.

Product lifecycle management (PLM) can

be part of one of the following four fundamentals of a manufacturing

information technology structure.

(i)

Customer Relationship Management (CRM)

(ii)

Supply Chain Management (SCM)

(iii)

Enterprise resource planning (ERP)

(iv)

Product Planning and Development (PPD).

The

core of PLM is in the formation and management of all product information and

the technology used to access this data and knowledge. PLM as a discipline

appeared from tools such as CAD, CAM and PDM, but can be viewed as the

combination of these tools with processes, methods and people through all

stages of a product’slife cycle. PLM is not just about software technology but

is

also

a business approach.

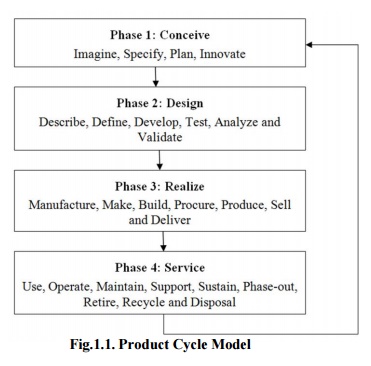

Product Cycle Model

There are several Product cycle models in industry

to be considered, one of the possible product

cycle

is given below (Fig.1.1.):

Fig.1.1.

Product Cycle Model

Step

1: Conceive

Imagine,

Specify, Plan, Innovate

The first step is the definition of the

product requirements based on company, market and customer. From this

requirement, the product's technical data can be defined. In parallel, the

early concept design work is performed defining the product with its main

functional features. Various media are utilized for these processes, from paper

and pencil to clay mock-up to 3D Computer Aided Industrial Design.

Step

2: Design

Describe,

Define, Develop, Test, Analyze and Validate

This is where the completed design and development

of the product begins, succeeding to prototype testing, through pilot release

to final product. It can also involve redesign and ramp for improvement to

existing products as well as planned obsolescence. The main tool used for

design and development is CAD. This can be simple 2D drawing / drafting or 3D

parametric feature based solid/surface modeling.

This step covers many engineering

disciplines including: electronic, electrical, mechanical, and civil. Besides

the actual making of geometry there is the analysis of the components and

assemblies.

Optimization, Validation and Simulation

activities are carried out using Computer Aided Engineering (CAE) software.

These are used to perform various tasks such as: Computational Fluid Dynamics

(CFD); Finite Element Analysis (FEA); and Mechanical Event Simulation (MES).

Computer Aided Quality (CAQ) is used for activities such as Dimensional tolerance

analysis. One more task carried out at this step is the sourcing of bought out

components with the aid of procurement process.

Step 3: Realize

Manufacture, Make, Build, Procure, Produce, Sell and

Deliver

Once the design of the

components is complete the method of manufacturing is finalized. This includes

CAD operations such as generation of CNC Machining instructions for the

product’s component as well as tools to manufacture those components, using

integrated Computer Aided Manufacturing (CAM) software.

It includes Production Planning tools

for carrying out plant and factory layout and production simulation. Once

details components are manufactured their geometrical form and dimensions can

be verified against the original data with the use of Computer Aided Inspection

Equipment (CAIE). Parallel to the engineering tasks, sales and marketing work

take place. This could consist of transferring engineering data to a web based

sales configuration.

Step

4: Service

Use,

Operate, Maintain, Support, Sustain, Phase-out, Retire, Recycle and Disposal.

The

final step of the lifecycle includes managing of information related to service

for repair and maintenance, as well as recycling and waste management

information. This involves using tools like Maintenance, Repair and Operations

Management software.

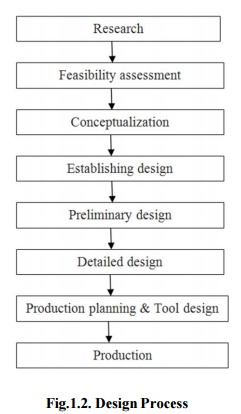

Design Process

The design process includes series of

steps that engineers apply in making functional products and processes. The

parts of the process often need to be repeated many times before production of

a product can start. The parts that get iterated and the number of such design

cycles in any given project can be highly changeable.

One

method of the engineering design process focuses on the following common

aspects:

Fig.1.2.

Design Process

1.

Research

A

considerable amount of time is used on research, or finding information.

Consideration should be given to the available applicable literature, issues

and successes linked with avaialbe solutions, and need of marketplaces.

The

basis of information should be significant, including existing results. Reverse

engineering can be a successful technique if other solutions are available in

the market. Added sources of information include the trade journals, available

government documents, local libraries, vendor catalogs and personal

organizations.

2.

Feasibility assessment

The feasibility study

is an analysis and assessment of the possible of a proposed design which is

based on detail investigation and research to maintain the process of decision

creation. The feasibility assessment helps to focus the scope of the project to

spot the best situation. The purpose of a feasibility assessment is to verify

whether the project can continue into the design phase.

3. Conceptualization

A Concept Study is the stage of project

planning that includes developing ideas and taking into account the all

features of executing those ideas. This stage of a project is done to reduce

the likelihood of assess risks, error and evaluate the potential success of the

planned project.

4.

Establishing the design requirements

Establishing design requirements is one

of the most essential elements in the design practice, and this task is usually

performed at the same time as the feasibility analysis. The design requirements

control the design of the project all over the engineering design process. A

few design

requirements comprise maintainability, hardware and

software parameters, availability, and testability.

5.

Preliminary design

The preliminary design

fills the gap between the design concept and the detailed design phase. During

this task, the system configuration is defined, and schematics, diagrams, and

layouts of the

project will offer

early project configuration. In detailed design and optimization, the

parameters of the part being produced will change, but the preliminary design

focuses on creating the common framework to construct the project.

6. Detailed

design

The next phase of

preliminary design is the Detailed Design which may includes of procurement

also. This phase builds on the already developed preliminary design, aiming to

further

develop each phase of

the project by total description through drawings, modeling as well as specifications.

The advancement CAD

programs have made the detailed design phase more competent. This is because a

CAD program can offer optimization, where it can shrink volume without

compromising the part's quality. It can also calculate displacement and stress

using the FEM to find stresses throughout the part. It is the responsibility of

designer to find whether these stresses and displacements are acceptable, so

the part is safe.

7. Production

planning and tool design

The production planning and tool design is more than

planning how to mass-produce the project and which tools should be used in the

manufacturing of the component. Tasks to complete in this stage include

material selection, identification of the production processes, finalization of

the sequence of operations, and selection of jigs, fixtures, and tooling. This

stage also includes testing a working prototype to confirm the created part

meets qualification standards.

With the finishing of

qualification testing and prototype testing, the design process is completed.

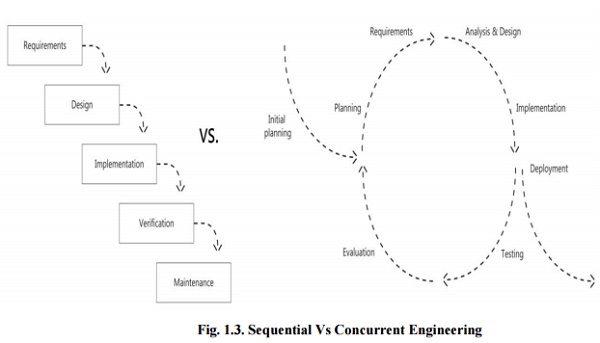

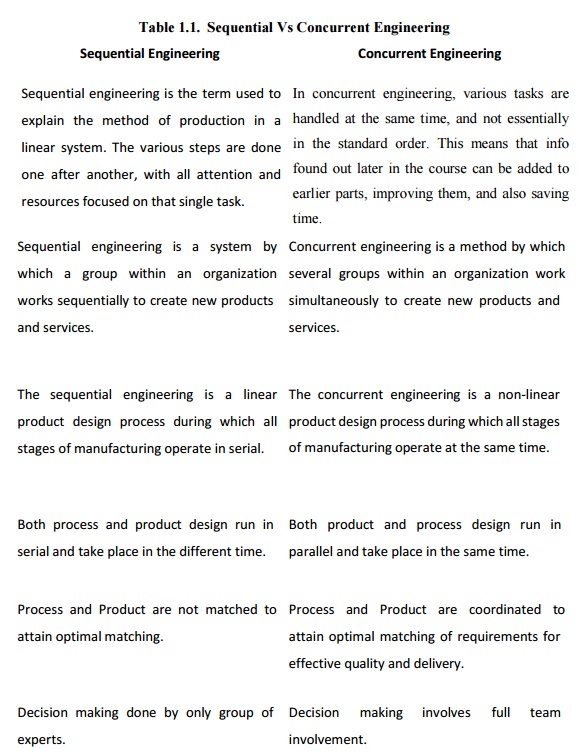

Sequential

and Concurrent Engineering

Table

1.1. Sequential Vs Concurrent Engineering

Sequential Engineering

Sequential

engineering is the term used to explain the method of production in a linear

system. The various steps are done one after another, with all attention and

resources focused on that single task.

Sequential engineering

is a system

by which a

group within an

organization works sequentially

to create new products and services.

The

concurrent engineering is a non-linear product design process during which all

stages of manufacturing operate at the same time.

Both

process and product design run in serial and take place in the different time.

Process

and Product are not matched to attain optimal matching.

Decision

making done by only group of

experts.

Concurrent Engineering

In

concurrent engineering, various tasks are handled at the same time, and not

essentially in the standard order. This means that info found out later in the

course can be added to earlier parts, improving them, and also saving time.

Concurrent

engineering is a method by which several groups within an organization work

simultaneously to create new products and

services.

The sequential

engineering is a

linear product design process

during which all stages of manufacturing

operate in serial.

Both

product and process design run in parallel and take place in the same time.

Process and

Product are coordinated

to attain optimal matching of requirements for effective quality and

delivery.

Decision making

involves full team involvement.

Computer Aided Design

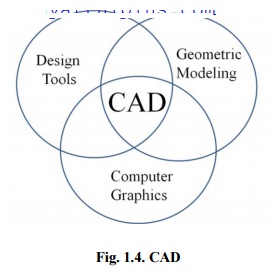

CAD is the intersection

of Computer Graphics, Geometric modeling and Design tools (Fig.1.4.). The concepts

of computer graphics and geometric modeling and must be used innovatively to

serve the design process.

CAD

is the function of computer systems to support in the creation, modification,

analysis, or optimization of a design.

Fig.

1.4. CAD

CAD software for design

uses either vector-based graphics to explain the objects of traditional

drafting, or may also develop raster graphics showing the overall look of

designed objects. During the manual drafting of engineering drawings, the output

of CAD must convey information, like dimensions, materials, processes, and

tolerances.

CAD is a significant

industrial art used in many purposes, including industrial and architectural

design, shipbuilding, automotive, and aerospace industries, and many more. CAD

is also extensively used to create computer animation for special effects in

movies, and technical manuals, frequently called as Digital Content Creation.

CAD software packages provide the

designer with a multi window environment with animation which is regularly used

in Digital Content Creation. The animations using wire frame modeling helps the

designer to see into the interior of object and to observe the behaviors of the

inner components of the assembly during the motion.

CAD Technology

Initially software

for CAD systems

was developed with

computer languages such

as

FORTRAN

but with the development of object-oriented programming

methods this has completely changed. Classic modern parametric attribute based

modeler and freeform surface

systems are developing around a number of key ‘C’modules.

A CAD system can be

seen as develop from the interaction of a Graphical User

Interface (GUI) with NURBS geometry and

Boundary representation data through a kernel for geometric

modeling. A geometry constraint engine may also be

employed to organize the associative relationships between

components in an assembly.

Unexpected facilities

of these relationships have led to a new form of prototyping

called digital

prototyping. In

difference to physical prototypes, which involve manufacturing time in the

design. CAD models can be created by a computer after the physical prototype

has been scanned using an CT

scanning

device. Based on the nature of the business, digital or physical prototypes can

be primarily

selected according to specific requirements.

Currently, no special

hardware is required for CAD software. However, some special CAD systems can do

graphically and computationally intensive tasks, so a higher end graphics card,

high speed CPUs may be suggested. CAD systems exist for all the major platforms

and some packages even

perform multiple platforms.

The human-machine

interface is generally

through a mouse but can

also be using

a

digitizing graphics

tablet. Handling of the view of the part on the screen is also sometimes done

with the help of a Space mouse or Space Ball. Special CAD systems also support

stereoscopic glasses for viewing the 3D

objects.

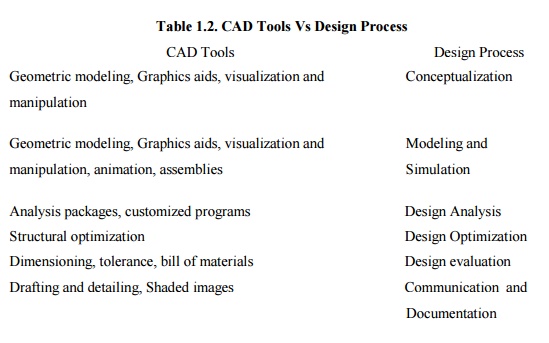

CAD Tools

The

CAD tools are mainly using for graphics applications and modeling. Aids such a

color, grids, geometric modifiers and group facilitate structural geometric

models. Visualization is achieved through shaded components and animation which

focus design conceptualization, communication and interference detection. FEM

packages provide optimization in shape and structure. Adding tolerances,

tolerance analysis and investigating the effect of manufacturing on the design

can perform by utilizing CAD tools (Table 1.2).

Table 1.2. CAD Tools Vs Design

Process

CAD Tools : Design Process

Geometric

modeling, Graphics aids, visualization and manipulation : Conceptualization

Geometric

modeling, Graphics aids, visualization and Modeling

and manipulation, animation, assemblies : Simulation

Analysis

packages, customized programs : Design

Analysis

Structural

optimization : Design Optimization

Dimensioning,

tolerance, bill of materials : Design

evaluation

Drafting

and detailing, Shaded images :

Communication and Documentation

Uses of CAD

CAD is one of the tools used by

designers and engineers and is used in different ways depending on the

profession of the customer and the type of software.

CAD is one of the Digital Product

Development activities within the Product

Lifecycle Management

practices with other tools, which are either integrated modules or individual,

such as:

· Computer Aided

engineering (CAE) and Finite Element

Analysis (FEA)

· Computer Aided

Manufacturing (CAM)

· Realistic

Rendering and Simulation.

· Product

Data Management (PDM).

CAD is also used for

the development of photo simulations that are frequently necessary in the

preparation of Environmental Impact Reports, in which proposed CAD buildings

are superimposed into photographs of existing situation to represent what that

conditions will be like, where the proposed services are allowed to be built.

Parameters and constraints can be used

to get the size, shape, and other properties of the modeling elements. The

features of the CAD system can be used for the several tools for measurement

such as yield strength, tensile strength and electrical or electro-magnetic

properties.

CAD System Architecture

Computer architecture

is a pattern describing how a group of software and hardware technology

standards relate to form a computer system. In general, computer architecture

refers to how a computer is designed and what technologies it is compatible

with. Computer architecture is likened to the art of shaping the needs of the

technology, and developing a logical design and standards based on needs.

In CAD, Computer

architecture is a set of disciplines that explains the functionality, the

organization and the introduction of computer systems; that is, it describes

the capabilities of a computer and its programming method in a summary way, and

how the internal organization of the system is designed and executed to meet

the specified facilities. Computer architecture engages different aspects,

including instruction set architecture design, logic design, and

implementation. The implementation includes Integrated Circuit Design, Power,

and Cooling. Optimization of the design needs expertise with Compilers, Operating

Systems and Packaging.

Instruction

set architecture

An instruction set architecture is the interface between the software and hardware and also can be observed as the programmer's view of the machine. Computers do not understand high level languages, if any, language elements that translate directly into a machine's native op codes.

Related Topics