Chapter: Mechanical : Computer Aided Design : Fundamentals of Computer Graphics

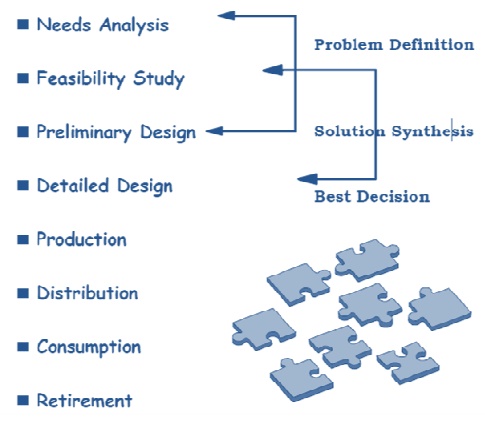

Morphology of Design

MORPHOLOGY OF DESIGN

The consideration of the product life from its conception to retire ment.....

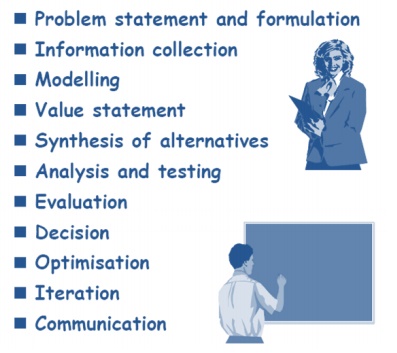

Anatomy of Design

Detailed examination of th e engineer’s actions as he/she identifies and solves the problem:

1.Needs Analysis

Creation begins by recognizing a need

O Apparent fr om observation

O Results of a detailed study

O A specific s et of circumstances

Results in a primiti ve statement

O Fact or opi nion

O Does the ne ed exist and is it realistic?

O Does it exis t now or will it exist in the future?

O Is it a new need? (new material or physical principle)

Often depends on c ircumstances

Needs analysis once through the Anatomy provides a good star ting point for the Feasibility Study

2. Feasibility Study

Designs can be futile unless satisfying the original need is feasible

At this stage, the product appears in abstract forms, but is they feasible???

Alternative solutions must be subjected to physical and economic analyses and be realizable from both

The Feasibility Study using analysis of several alternatives establishes the design concept as something which can be realised and accepted

Some examples.....

(i) A building must be comfortable to live in:

Heating, ventilation and air conditioning are required. Specify limits of temperature, humidity, velocity and fresh air constituency.

(ii) National fossil fuel supplies are low:

Alternative forms of energy supply are required. Specify amount and where they are needed, and any restrictions of space, time or pollution levels.

3.Preliminary Design

Main purpose is selection of the best possible solution from a choice of alternatives Make comparisons against given criteria & constraints

Must maintain an open mind; use your judgement.

4.Detailed design

Aim is to produce a complete set of working drawings which are then transmitted to the manufacturer

This stage of design is far less flexible than those previous

Design should now reflect all of the planning both for manufacture and consumption stages Construction/testing of various components may be required

Prototype building ....is it what was expected?

5.Production

Here, the device or system is actually constructed, and planning for this should have been incorporated into the design

Knowledge of the capability of the machines is required, since it must be possible to build and assemble the components as specified

Special jigs, fixtures and even machines may be required

Planning is vital; including quality control hold points, methods of inspection, standards for comparison etc...

Timing of construction may be important eg. Climatics

6.Distribution

Transportation of the ma nufactured article, complete or in subassem ly form must be anticipated in the design

Packaging, availability of vehicles, regulations for use of thoroughfares , shelf/component life, warehouse storage f acilities, special handling, environmental contr ol of temperature and humidity may need to be addressed

7.Consumption

The product is now used by the consumer

If the design is effect, it w ill have met the need

The design may yet no t be complete; redesigns and modifications may be required depending on field trials or consumer feedback

May need to consider maintenance of components and supply of spare parts or subassemblies

8.Retirement

The product will be discarded as its life cycle terminates

It may have become obsol ete whilst still serviceable and therefore the design may not have been fully economical

Disposal and recovery of u seful materials should have been included in the design Threats to safety should bee guarded against

Related Topics