Chapter: Biotechnology Applying the Genetic Revolution: Noninfectious Diseases

Cloning and Genetic Engineering of Insulin

CLONING

AND GENETIC ENGINEERING OF INSULIN

Insulin was the first genetically

engineered hormone to be made commercially available for human use. Before

cloned human insulin was available, people with diabetes had to give themselves

injections of insulin extracted from the pancreas of animals such as cows or

pigs. Although this worked well on the whole, occasional allergic reactions

occurred, usually to low-level contaminants in the extracts. Today, genuine

human insulin (Humulin, marketed by Eli Lilly Inc.) made by recombinant bacteria

is available.

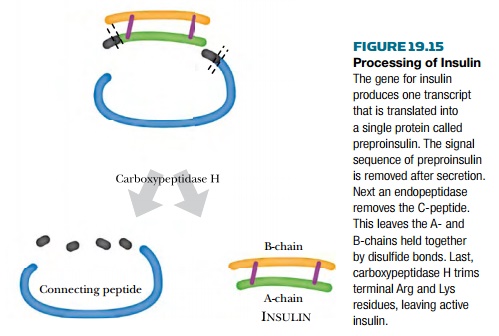

If the insulin gene is cloned and

directly expressed in bacteria, preproinsulin would be made. Because bacteria

lack the mammalian processing enzymes, the preproinsulin would not be converted

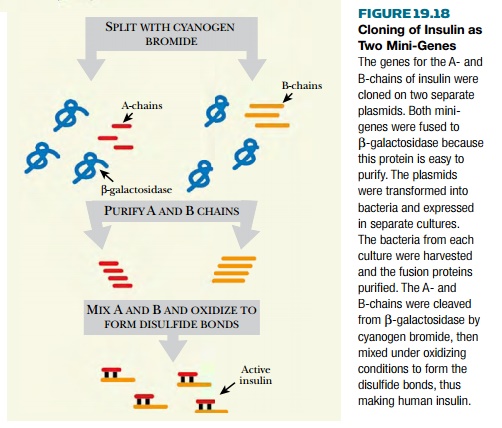

into insulin (see Fig. 19.15 ). In practice, there are two possible solutions

to this problem. The first is to purify the preproinsulin and then treat it with

enzymes that convert it into insulin. This means the processing enzymes must be

manufactured as well. Clearly this is overly complex. The solution chosen was

to make two artificial mini-genes , one for the insulin A-chain and the other for

the insulin B-chain ( Fig. 19.18 ).

Two pieces of DNA, encoding the two insulin

chains, were synthesized chemically. The two DNA molecules were inserted into

plasmids that were put into two separate bacterial hosts. Thus, the two chains

of insulin were produced separately by two bacterial cultures. They were then

mixed and treated chemically to generate the disulfide bonds linking the chains

together.

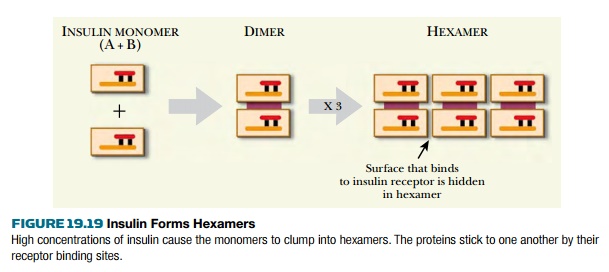

The approach just described gives

insulin that works well. Nonetheless, natural insulin, even natural human

insulin, is not perfect, and we can improve on nature. The problem is that

natural insulin tends to form hexamers. This clumping covers up the surfaces by

which the insulin molecule binds to the insulin receptor, thus preventing most of

the insulin from activating its target cells ( Fig. 19.19 ). In vivo, insulin

is secreted from the pancreas as a monomer and is distributed rapidly by the

bloodstream before it gets a chance to clump. However, when insulin is

injected, a high concentration of insulin is present in the syringe and

clumping occurs. After injection, it takes a while for the hexamers to

dissociate, and it may take several hours for the patient’s blood glucose to

drop to normal levels.

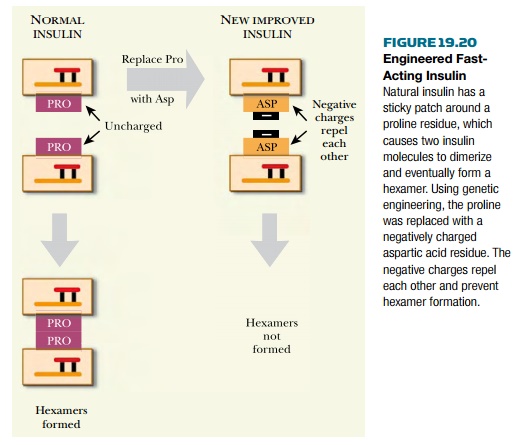

Insulin can be genetically engineered to

prevent clumping. The DNA sequence of the insulin gene is altered to change the

amino acid sequence of the resulting protein. A proline located at the surface

where the insulin molecules touch each other when forming the hexamer is

replaced with aspartic acid, whose side chain carries a negative charge. So when

twomodified insulin molecules approach each other, they are mutually repelled

by their negative charges and no longer clump ( Fig. 19.20 ). The altered

insulin causes a faster drop in blood sugar than native insulin. In 1999 the

Danish pharmaceutical company Novo received approval from the European Union,

and the improved insulin may eventually replace the natural product.

Related Topics