Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Sleepers

Types of concrete sleepers

Types

of concrete sleepers

The various types of concrete

sleepers (prestressed, pre-tension, post-tension, and two-block) being

manufactured by Indian Railways have been described in Table 7.6.

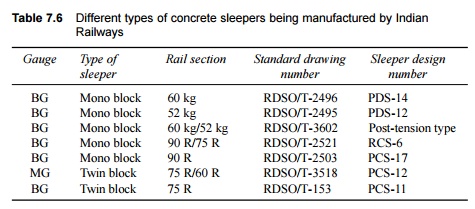

Table

7.6 Different

types of concrete sleepers being manufactured by Indian Railways

Mono-block prestressed concrete sleepers

with pandrol clips

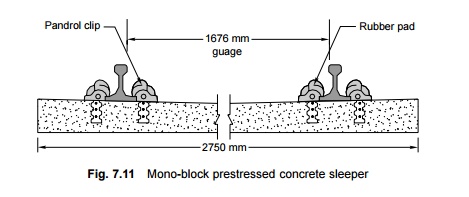

The

mono-block prestressed concrete sleeper (Fig. 7.11), which is similar to the

German B-58 type of sleeper, has an overall length of 2750 mm and a weight of

270 kg approximately. The sleeper has a trapezoidal cross section with a width

of 154 mm at the top and 250 mm at the bottom and a height of 210 mm at the

rail seat. A cant of 1 in 20 is provided on the top surface of the sleeper for

a distance of 175 mm on either side of the centre line of the rail to cover the

area of rail fittings. The sleeper is prestressed with 18 high tensile steel

(HTS) strands of 3 × 3 mm diameter and 12 6-mm-diameter mild steel links. The

initial prestressing of the steel is 100 kg/cm2. The 28-day crushing

strength of the concrete is normally not less than 525 kg/cm2.

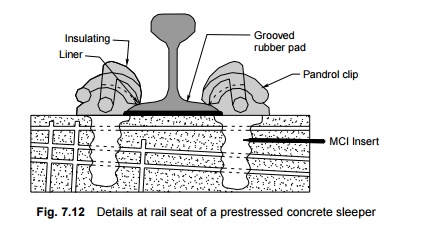

The rail

rests on a grooved 130 × 130 mm rubber pad, with the grooves lying parallel to

the axis of the rail. The fastenings provided for the 52-kg rail are Pandrol

clips, which are held in malleable cast iron inserts as shown in Fig. 7.12.

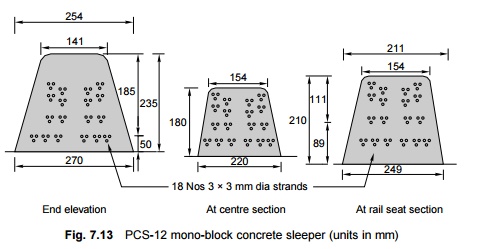

PCS-12 and PCS-14

PCS-12 is

the latest type of prestressed concrete (PRC) sleeper for use on BG routes with

52-kg rails and elastic rail clips. For use with 60-kg rails and elastic rail

clips, the PCS-14 sleeper has been standardized on Indian Railways.

The important dimensions of both

of these types of sleepers are shown in Fig. 7.13 and listed as follows.

l Length =

2750 mm

l Weight =

267 kg

l Reinforcement:

Eighteen 3 × 3 mm diameter strands

l Concrete

is to be of controlled quality with a minimum 28-day crushing strength of 525

kg/cm2

l Each

strand to be tensioned with an initial tensile force of 2730 kg

Mono-block post-tension type of concrete

sleepers for BG

The first factory in India for

the manufacture of post-tension type of mono-block concrete sleepers was set up

by Northern Railways at Allahabad in collaboration with M/s Dyckerhoff and

Widmann (D&W) of West Germany. The factory, which started production in

1981, has a planned capacity of manufacturing 300,000 concrete sleepers per

year. The salient feature of post-tension type of concrete sleepers are the

following.

Size of sleeper

l Length =

2750 mm

l Width at

centre = 160 mm (top)

200 mm

(bottom)

l Depth at

centre = 180 mm

l Weight =

295 kg

Design features

l Initial

prestressing force = 37 t

l Final

prestressing force = 31 t

l Minimum

concrete strength in 28 days = 550 kg/cm2

l Minimum

strength of concrete at the time of applying prestress = 450 kg/

cm2

The use of concrete sleepers

using the post-tension method has not been successful on Indian Railways and

its manufacture has since been stopped.

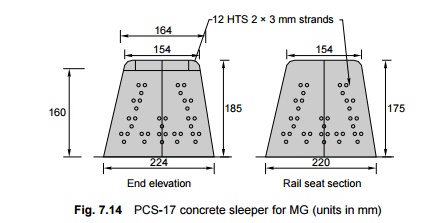

Mono-block PRC sleepers for MG (PCS-17)

A design

for mono-block PRC sleepers (PCS-17) has recently been standardized for MG. The

sleeper has a trapezoidal cross section similar to that of a BG sleeper. The

concrete should have a 28-day compressive strength of 525 kg/cm2.

The salient features of this sleeper are the following (Fig. 7.14).

l Length =

2000 mm

l Weight =

158.5 kg

Reinforcement:

Twelve 3 × 3 mm diameter strand of HTS wire tensioned to initial force of 2730

kg

PRC sleepers can be used for 90 R

rails with elastic rail clips and glass filled nylon liners (GFN 66) and on

sole plates.

Two-block RCC sleeper for BG yards

A design for a two-block RCC

sleeper for BG yards has been standardized by RDSO as per drawing number

RDSO/T-2521 for extensive trials on Indian Railways. There is a general

scarcity of wooden and CST-9 sleepers for use in BG yards and the new RCC

sleepers will ease the situation in a big way. Some of the salient features of

this sleeper are as follows.

l Considering

low speeds in yard lines and less impact effect, the rail seat design load has

been taken only as 10 t without any lateral thrust.

l

Size at rail seat (top width × bottom width ×

depth) = 22 cm × 30 cm × 17 cm

l Overall

length of the sleeper = 247.5 cm

l Weight of

the sleeper = 170 kg

l Main

reinforcement in each block

n At top: Five 8-mm-diameter steel bars

n At bottom: Two 8-mm-diameter steel bars

l The

fastenings used are steel clips and a spring washer with screw fitted to

a

polythene dowel.

Two-block concrete sleeper for MG yards

Two-block concrete sleepers for

use in MG yards have recently been developed. The sleeper consists of two

cement concrete blocks, each weighting about 36 kg and consisting of an MS

reinforcement of about 7 kg. The two RCC sleeper blocks are connected by an

angle tie bar of 55 × 50 × 6 mm section and 1.5 m length. The rail is fixed to

the sleeper block either by a clip and bolt arrangement or by polythene dowels

and rail screws. A pad is provided below the rail seat to provide cushioning.

Mono-block versus two-block concrete

sleepers

There are relative advantages and

disadvantages of mono-block and two-block concrete sleepers. Some of these are

enumerated below.

(a) Mono-block

sleepers give better longitudinal and lateral stability to the track compared

to two-block concrete sleepers.

(b) The

mono-block concrete sleeper, being a monolithic concrete mass, is likely to

have a longer working life compared to the two-block concrete sleeper connected

with a tie bar. In the latter case, a tie bar is weak and has a comparatively

shorter life due to corrosion, etc.

(c) The

mono-block concrete sleeper requires heavy capital expenditure for its

manufacture, being a prestressed reinforced concrete unit, compared to the

two-block sleeper, which is an ordinary reinforced concrete sleeper.

(d) In a

mono-block prestressed concrete sleeper, a crack that develops because of

overstressing is likely to close down upon return to normal condition, whereas

in a two-block sleeper, such a crack will continue to remain open.

(e) Mono-block

sleepers are likely to become centre-bound unlike two-block sleepers.

(f) During

derailments and rough handling the tie bars of two-block sleeper get deformed,

thereby affecting the gauge.

(g) In a

two-block sleeper, the two blocks are not likely to rest on the ballast in a

way that each rail is properly inclined to the vertical, a feature which could

affect the alignment and gauge of the track.

Related Topics