Chapter: Mechanical : Robotics : Fundamentals of Robot

Robot Parts and Functions

Robot Parts and Functions

The controller is the "brain" of the industrial

robotic arm and allows the parts of the robot to operate together. It works as

a computer and allows the robot to also be connected to other systems. The robotic arm controller runs a set of

instructions written in code called a program. The program is inputted

with ateach pendant. Many of

today's industrial robot arms use an

interface that resembles or is built on the Windows operating system.

Industrial robot arms

can vary in size and shape. The industrial

robot arm is the part that positions the end effector. With the robot arm, the shoulder, elbow, and wrist

move and twist to position the end effector in the exact right spot. Each of

these joints gives the robot another degree of freedom. A simple robot with

three degrees of freedom can move in three ways: up & down, left &

right, and forward & backward. Many

industrial robots in factories today are six axis robots.

The end effector

connects to the robot's arm and functions as a hand. This part comes in direct

contact with the material the robot is manipulating. Some variations of an

effector are a gripper, a vacuum pump, magnets, and welding torches. Some robots are capable of

changing end effectors and can be programmed for different sets of tasks.

The drive is the

engine or motor that moves the links into their designated positions. The links

are the sections between the joints. Industrial

robot arms generally use one of the following types of drives: hydraulic,

electric, or pneumatic. Hydraulic drive systems give a robot great speed and

strength. An electric system provides a robot with less speed and strength.

Pneumatic drive systems are used for smaller robots that have fewer axes of

movement. Drives should be periodically inspected for wear and replaced if

necessary.

Sensors allow the

industrial robotic arm to receive feedback about its environment. Theycan give

the robot a limited sense of sight and sound. The sensor collects information

and sends it electronically to the robot controlled. One use of these sensors

is to keep two robots that work closely together from bumping into each other.

Sensors can also assist end effectors by

adjusting for part variances. Vision sensors allow a pick and place robot to differentiate between

items to choose and items to ignore.

Controller:

Every robot is

connected to a computer, which keeps the pieces of the arm working together.

This computer is known as the controller.

The controller

functions as the "brain"of the robot. The controller also allows the

robot to be networked to other systems, so that it may work together with other

machines, processes, or robots.

Robots today have controllers that are run by

programs - sets of instructions written in code. Almost all robots of today are

entirely pre-programmed by people; they can do only what they are programmed to

do at the time, and nothing else. In the future, controllers with artificial

intelligence, or AI could allow robots to think on their own, even program

themselves. This could make robots more self-reliant and independent.

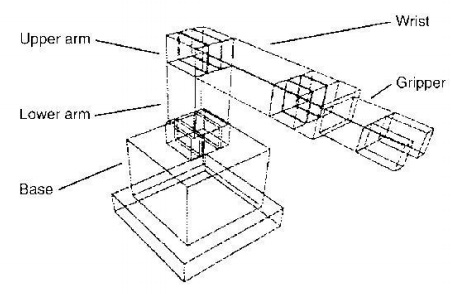

Arm:

Robot arms come in all

shapes and sizes. The arm is the part of the robot that positions the end-

effector and sensors to do their pre-programmed business. Many (but not all)

resemble human arms, and have shoulders, elbows, wrists, even fingers.

This gives the robot a

lot of ways to position itself in its environment. Each joint is said to give

the robot 1 degree of freedom. So, a simple robot arm with 3 degrees of freedom

could move in 3 ways: up and down, left and right, forward and backward.

Drive:

The drive is the

"engine" that drives the links (the sections between the joints into

their desired position. Without a drive, a robot would just sit there, which is

not often helpful. Most drives are powered by air, water pressure, or electricity.

End-Effector:

The end-effector is the

"hand" connected to the robot's arm. It is often different from a

human hand - it could be a tool such as a gripper, a vacuum pump, tweezers,

scalpel, blowtorch - just about anything that helps it do its job. Some robots

can change end-effectors, and be reprogrammed for a different set of tasks.

Sensor:

Most robots of today are nearly deaf and blind.

Sensors can provide some limited feedback to the robot so it can do its job.

Compared to the senses

and abilities of even the simplest living things, robots have a very long way

to go.

The sensor sends information, in the form of electronic signals back to the controller. Sensors also give the robot controller information about its surroundings and let it know the exact position of the arm, or the state of the world around it.

Related Topics