Chapter: Mechanical : Robotics : Fundamentals of Robot

Robot Classification

Robot

Classification

Degree

of Freedom (D.O.F) - Each joint on the robot introduces a

degree of freedom. Each dof can be a slider, rotary, or other type of

actuator. Robots typically have 5 or 6 degrees of freedom. 3 of the degrees of

freedom allow positioning in 3D space, while the other 2or 3 are used for

orientation of the end effector. 6 degrees of freedom are enough to allow the

robot to reach all positions and orientations in 3D space. 5 D.O.F requires a

restriction to 2D space, or else it limits orientations. 5 D.O.F robots are

commonly used for handling tools such as arc welders.

Work Volume/Workspace - The robot tends to have a fixed and limited geometry. The work envelope is the boundary of positions in space that the robot can reach. For a Cartesian robot (like an overhead crane) the workspace might be a square, for more sophisticated robots the workspace might be a ntersshapecthating looksbubbles’li

The Pneumatic Robot.

The pick and place

machine is the simplest of the robots. Pneumatic powered, it has no servo

motors driving the axes, but an air cylinder instead.

As such, each stoke is

to an end stop, that is generally adjustable for a few millimeters, via a

micrometer type screw.

A

popular application is to pick and place small components into an assembly,

maybe from a vibratory bowl feeder to an assembly fixture.

Pick and Place units

are fast, accurate and very cost effective.

The Scara Robots.

Scara means Selective,

Compliant, Robot arm.This robot is especially designed for assembly automation

and uses 4-axes of motion, each axes driven by a servo motor. The two joints

have a motor each and the base has a rotate axis.

The forth axis is the

vertical axis that generally inserts a component. This arrangement makes a very

"stiff" arrangement that is ideally suited for accurate insertion.

The Scara is the least expensive of the servo powered robots and are usually

small and can be very fast. The photo at left is of an Epson robot. Take a look

at this page for more details- The Scara Robots.

The Gantry Robot.

This type of robot is

generally mounted direct to the shop floor and usually has a large work

envelope.

It can be used for

material handling applications and I used them for stacking and de-stacking

steel blanks, that were laser welded into tailored blanks.

They can be pneumatic

powered but the cost of servo drives for industrial robotics is getting so

competitive that today the air powered types are few and far between.

More details can be

found by visiting this page- The Gantry Robot.

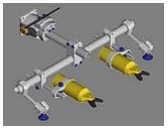

Cartesian robots.

These machines are

usually mounted on a table and are similar in concept to the gantry robot but

on a smaller scale. The axes can be air or servo motor powered and are

generally offered in modules, that are complete and can be bolted together, to

form the motions required.

The photo shows a Toshiba

robot.

The 6-Axes Industrial

Robot Arm.

Maybe the

most recognized industrial robot. It is available in a wide

range of sizes and payloads, They can be small enough to mount on a table or,

like the ABB IR 140 shown here are floor mounted.

Applications are

universal in the field of industrial robotics. The robot arm can be found in

all types of uses, from assembly to welding to painting and material handling.

The Painting Robot.

When used in a painting

application, the robot does not need a large payload capability but does need

good repeatability and accurate path following.When correctly programmed and

well maintained, a paint robot will produce excellent repeatable results with

no paint runs or overspray.

The photo shows an ABB

IRB 52.

The Welding Robot.

The welding robot does

not require a large payload capability but a larger work envelope can be an

advantage and smooth, non-jerky movement is required. Welding is a dirty

operation, so sealing of critical areas is essential and the shielding gas used

in MIG operations must ensure that weld spatter is kept tp a minimum.

Robot Grippers.

A most important detail

in industrial robotics is the part/ robot interface.Grippers come in many sizes

and different types. The photo shows an SMC gripper that is available in

various bore sizes and is toggle operated. The toggle has the effect of

increasing the clamping force and can provide gripping when pneumatic power is

absent.

Robotic End of Arm

Tooling.

The E.O.A.T. ( End Of

Arm Tooling), in industrial robotics, is an essential component of the whole.

Custom designed tooling can be very complicated. The fact that modular

components are available reduces the technical risk and cost of many

applications.

Related Topics