Chapter: Mechanical and Electrical : Power Plant Engineering : Coal Based Thermal Power Plants

Forced Draught, Induced Draught, Balanced Draught and Artificial Draught

a) Forced Draught b) Induced Draught c) Balanced Draught

Artificial Draught

It has

been seen that the draught produced by chimney is affected by the atmospheric

conditions. It has no flexibility, poor efficiency and tall chimney is

required. In most of the modern power plants, the draught used must be

independence of atmospheric condition, and it must have greater flexibility

(control) to take the fluctuating loads on the plant.

Today’srgelasteam power plants requiring 20 thousand tons

of steam per hour would be impossible to run without the aid of draft fans. A

chimney of an reasonable height would be incapable of developing enough draft

to remove the tremendous volume of air and gases (400 × 103 m3

to 800 × 103 m3 per minutes). The further advantage of

fans is to reduce the height of the chimney needed.

The draught required in actual power plant is sufficiently

high (300 mm of water) and to meet high draught requirements, some other system

must be used, known as artificial draught. The artificial draught is produced

by a fan and it is known as fan (mechanical) draught. Mechanical draught is

preferred for central power stations.

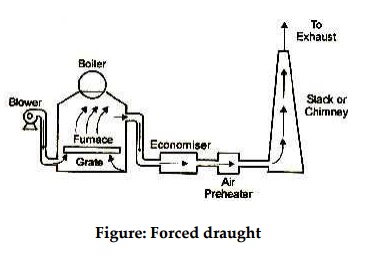

Forced

Draught

In a forced draught system, a blower is installed near the

base of the boiler and air is forced to pass through the furnace, flues,

economizer, air-preheater and to the stack. This draught system is known as

positive draught system or forced draught system because the pressure and air

is forced to flow through the system. The arrangement of the system is shown in

figure. A stack or chimney is also in this system as shown in figure but its

function is to discharge gases high in the atmosphere to prevent the

contamination. It is not much significant for producing draught therefore

height of the chimney may not be very much.

Figure: Forced draught

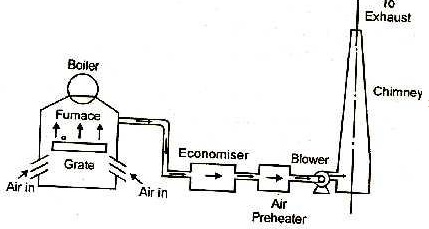

Induced

Draught:

In this system, the blower is located near the base of the

chimney instead of near the grate. The air is sucked in the system by reducing

the pressure through the system below atmosphere. The induced draught fan sucks

the burned gases from the furnace and the pressure inside the furnace is

reduced below atmosphere and induces the atmospheric air to flow through the

furnace. The action of the induced draught is similar to the action of the

chimney. The draught produced is independent of the temperature of the hot

gases therefore the gases may be much

heat as possible in air-preheater and an izer and air-preheater are

incorporated in the hat the temperature of the gas handled by the em and its

function is similar as mentioned in forced draught but total draught produced

in induced draught system is the sum of the draughts produced by the fan and

chimney. The arrangement of the system is shown in figure.

Figure:

Induced draught

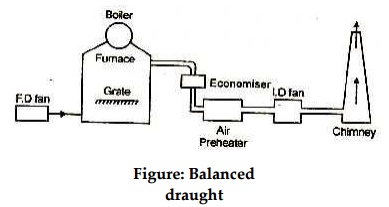

Balanced Draught:

It

is always preferable to use a combination of forced draught and induced draught

instead of forced or induced draught alone.

If

the forced draught is used alone, then the furnace cannot be opened either for

firing or inspection because the high pressure air inside the furnace will try

to blow out suddenly and there is every chance of blowing out the fire

completely and furnace stops.

If the induced draught is used alone, then also furnace

cannot be opened either for firing or inspection because the cold air will try

to rush into the furnace as the pressure inside the furnace is below

atmospheric pressure. This reduces the effective draught and dilutes the

combustion.

To

overcome both the difficulties mentioned above either using forced draught or

induced draught alone, a balanced draught is always preferred. The balanced

draught is a combination of forced and induced draught. The forced draught

overcomes the resistance of the fuel bed there fore sufficient air is supplied

to the fuel bed for proper and complete combustion. The induced draught fan

removes the gases from the furnace maintaining the pressure in the furnace just

below atmosphere. This helps to prevent the blow –off of flames when the doors

are opened as the leakage of air is inwards.

The

arrangement of the balanced draught is shown in figure. Also the pressure

inside the furnace is near atmospheric therefore there is no danger of blowout

or there is no danger of inrushing the air into the furnace when the doors are

opened for inspection.

Related Topics