Chapter: Civil : Principles of Solid Mechanics : Stress-Strain Relationships (Rheology)

Yield(Slip) of Brittle Materials

Yield (Slip) of

Brittle Materials

So far we have assumed

that our material has equal yield strength in tension or compression. However,

this is never quite true even for pure metals and mild steel. All materials, in

fact, have a somewhat higher yield strength in compres-sion than in tension

and, if this difference is pronounced, the material is brittle.** Common

engineering materials of this sort are cast iron, concrete, rock, and soil,

including sand, which has no tensile strength whatsoever.

The simplest conceptual

model for a brittle material is to visualize that all materials have two types

of shear strength:

a) Natural

or inherent strength due to primary and/or secondary bonds that glue

together atoms, molecules, crystals, or particles, and

b) Dry

friction or Coulomb friction.

Coulomb recognized and

incorporated them both in his more powerful ver-sion of the Tresca theory.

Because it is best described in terms of Mohr's Circle, this elegant and

unifying concept is today called the Mohr-Coulomb Theory.

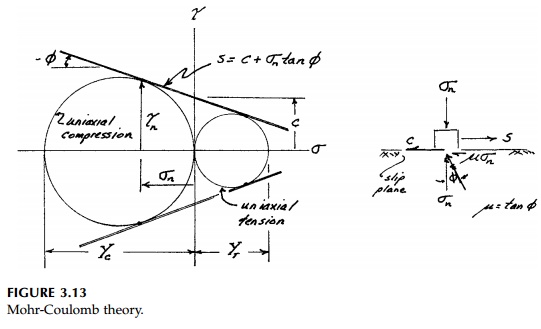

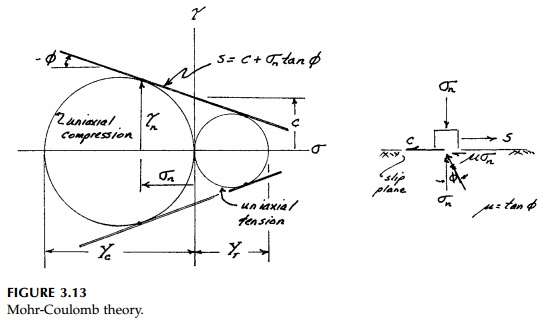

The simplest version is shown in Figure 3.13. It

will be discussed in much more detail later since it represents all engineering

materials to a reasonable

approximation. In terms of a rheological model, the

simple EPS must now include the normal stress _n

on the slip plane, which adds a component to the strength proportional to the

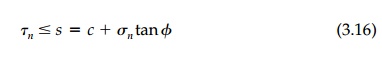

coefficient of friction. Thus the Mohr-Coulomb criterion is written:

which is the envelope

of the Mohr Circles for each test in stress space. The 'cohesion,' c,

represents the inherent or natural shear strength which, for a ductile EPS,

would be Y/2. The Mohr-Coulomb criterion is, therefore, non-linear. For

easier computations it can be stated in terms of max or oct

rather than the shear stress on the actual slip surface, n.

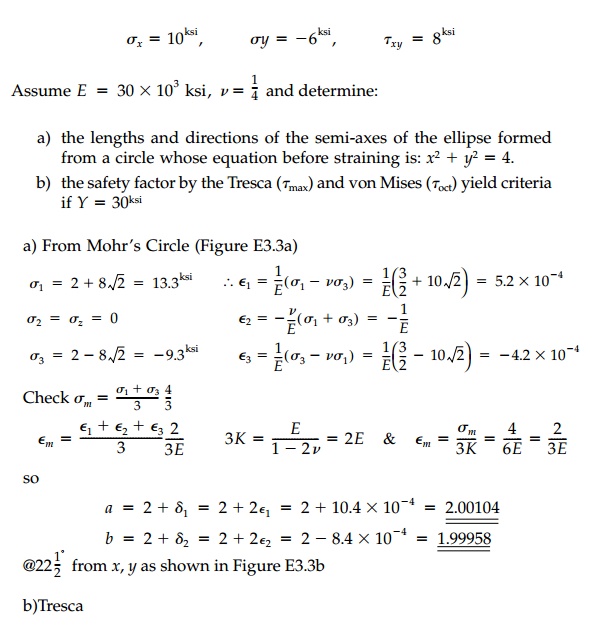

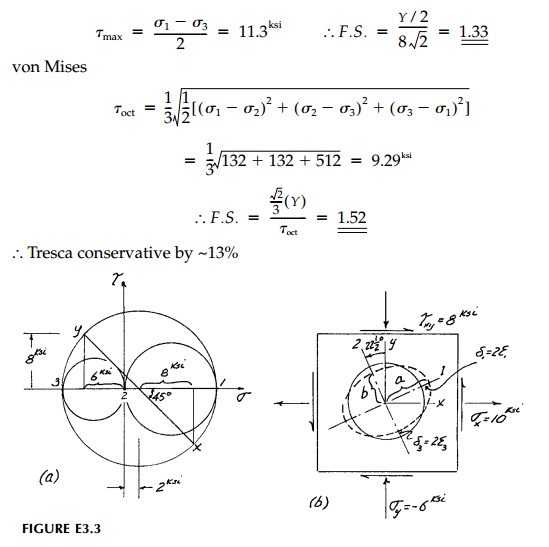

Example 3.3

A plate (plane stress) is subjected to the constant

stress field:

Related Topics