Chapter: Civil : Principles of Solid Mechanics : Stress-Strain Relationships (Rheology)

Fitting Laboratory Data with Viscoelastic Models

Fitting

Laboratory Data with Viscoelastic Models

Properties of

viscoelastic materials are usually determined in the laboratory with a creep

test run at constant temperature. Often a tensile test is used with

mea-surements of axial and transverse deformations as a function of time to

deter-mine E(t) and v(t). It is

better (often necessary) to run separate creep tests in pure states of constant

isotropic and deviatoric stress to determine K(t) and G(t)

indi-vidually, since for some linear viscoelastic materials, the elastic

relationships between E, v, G, and K

do not translate directly when they are functions of time.

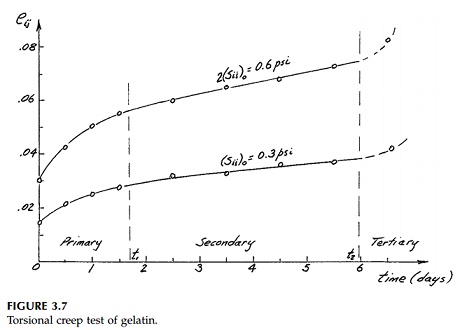

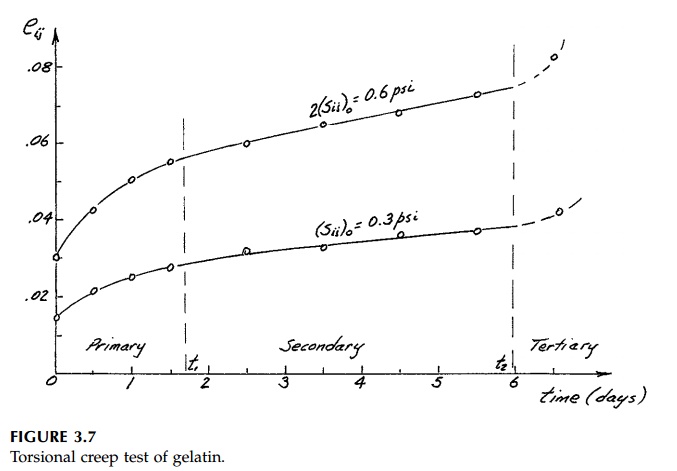

Typical results that were obtained in the laboratory

for the creep of gelatin* (in this case a mixture of 10% gelatin, 50% glycerin,

and 40% water) in pure shear at room temperature are shown in Figure 3.7. One

might decide to fit such curves with a least-squares polynomial, but it is much

better, since it is physical and leads to easier mathematics, to combine linear

springs and dashpots. As we have seen for the Maxwell, Kelvin, and standard

solid models, this leads to a differential equation for the behavior of a

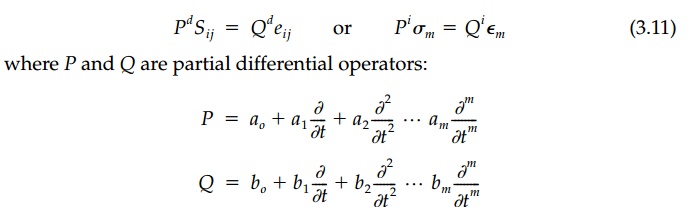

particular arrange-ment of springs and dashpots of the form:

with the coefficients ai and bi,

various combinations of Gi and ![]() i

in the devia-toric case (i.e., for Pd and Qd),

or Ki and

i

in the devia-toric case (i.e., for Pd and Qd),

or Ki and ![]() i

for the isotropic case (i.e., for Pi and Qi).

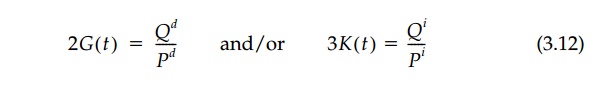

Thus we can derive time dependent moduli:

i

for the isotropic case (i.e., for Pi and Qi).

Thus we can derive time dependent moduli:

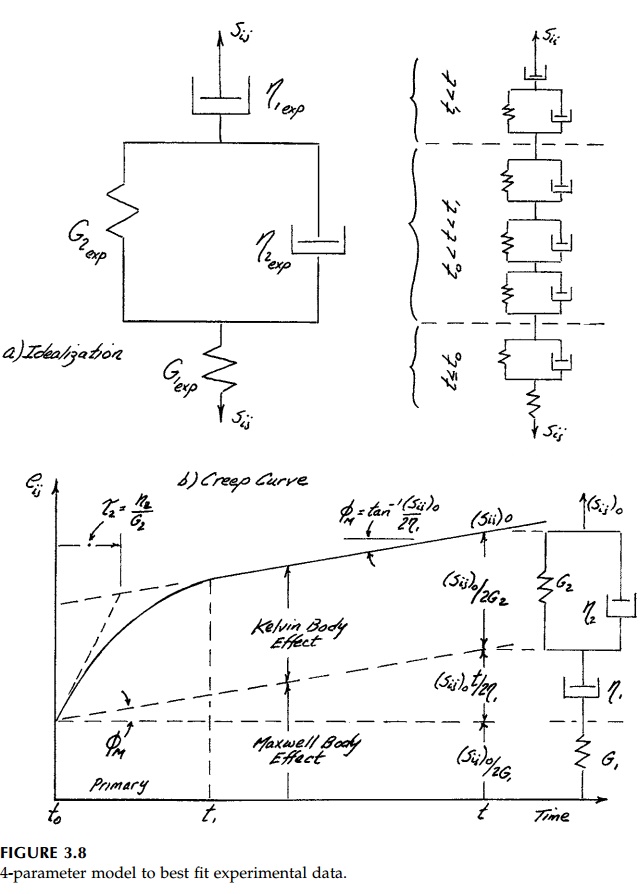

A combination of either

n Maxwell models in parallel or n Kelvin models in series with a

simple Maxwell model can represent observed linear vis-coelastic behavior to

any degree of accuracy desired. However, a 4-parameter model (Burger body)

shown in Figure 3.8 will generally capture the funda-mentals of the viscoelastic

response with sufficient accuracy for most engi-neering purposes. The

deformation at the first time reading, t to , is modeled by a

spring and primary behavior, to <

t < t1, by a single Kelvin body. The

contribution of each element is shown in Figure 3.8. Time t1

is chosen to be where, by eye, the creep curve plotted from the experimental

data appears to become a straight line at the angle ![]() M.

The initial tangent to the curve at t=to is drawn and

M.

The initial tangent to the curve at t=to is drawn and ![]() 2

determined as shown.

2

determined as shown.

The basic equation for the 4-parameter model is:

From t1, ![]() 2, and

2, and ![]() M

as found from the experimental curve drawn by eye to best fit the laboratory

data, the element parameters G1, G2,

M

as found from the experimental curve drawn by eye to best fit the laboratory

data, the element parameters G1, G2, ![]() ,

, ![]() 2

can be com-puted. If, as in Figure 3.6, the experiment indicates that bonds

begin to weaken at large strains, this tertiary behavior can be represented by

plastic elements such as those discussed later.

2

can be com-puted. If, as in Figure 3.6, the experiment indicates that bonds

begin to weaken at large strains, this tertiary behavior can be represented by

plastic elements such as those discussed later.

Related Topics