Chapter: Civil : Principles of Solid Mechanics : Stress-Strain Relationships (Rheology)

Simple Viscoelastic Behavior

Simple

Viscoelastic Behavior

All solids are to some extent 'fluid' in that they

will flow, even if only a minuscule amount, at working stress levels if enough

time passes. Thus stress-strain relationships are actually functions of time

(and temperature) and it can be dangerous, even disastrous, to neglect creep

effects in such mate-rials as concrete, plastics, wood, or soil when

dimensional tolerances must be maintained over time.* Moreover, as we might

expect, an increase in temper-ature accelerates viscous flow. All solids turn

into liquids or (gases) at their melting point, but long before that, many

materials such as metals (which appear elastic at room temperature) will loose

stiffness and become viscous** at higher temperatures. Such viscous flow, which

can occur under either iso-tropic or deviatoric stress, is easily confused with

plastic flow which, as we will see, is a purely deviatoric phenomenon. However,

in areas of plastic flow,

(*For example,

time-dependent creep distortion of the concrete in Hoover dam (where the load

is essentially constant) eventually (after forty years), necessitated

replacement of the steel pen-stock liners at great expense. Creep of concrete

and wood can reduce effective prestress signifi-cantly (or destroy shallow

arches) and the long-term deviatoric creep sometimes thought of as secondary

consolidation can, even after hundreds of years, lead to foundation failure as

wit-nessed in the Tower of Pisa.

**The melting point of iron, for example, is 1535 o C

but at only 300 o C it begins to flow under load. That is why

unprotected steel buildings have a lower fire rating (higher insurance

premiums) than concrete or even wooden ones.

)

all distortional

resistance is gone* and there is therefore no deviatoric stiffness. An increase

in temperature will reduce both the deviatoric stiffness and the yield

strength, but it is important to keep the two properties, stiffness and

strength, separate in our minds.

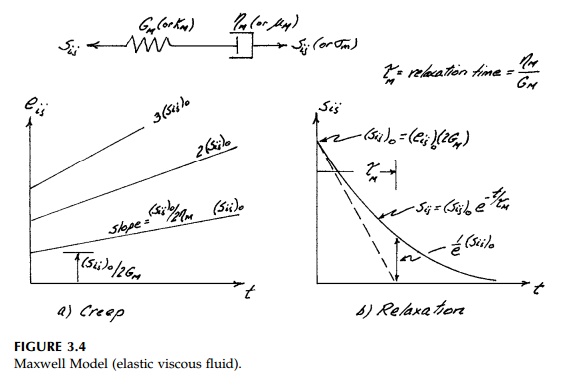

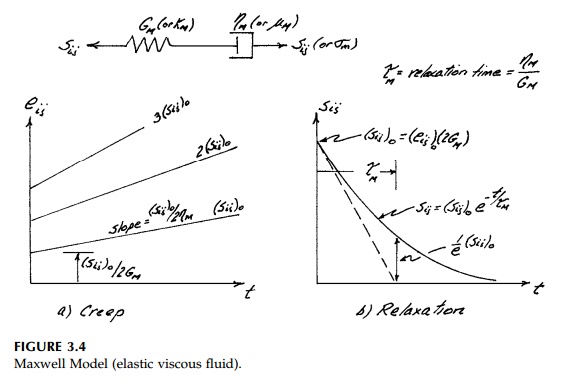

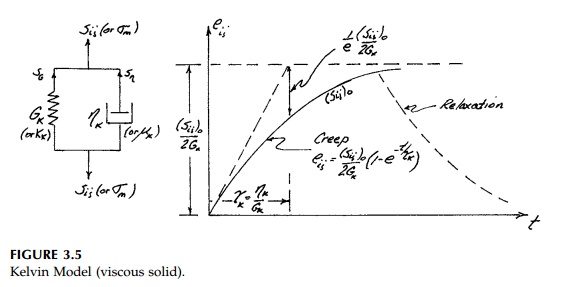

Elastic behavior can be

modified to include viscous effects by combining dashpots with springs to any

degree of complexity deemed necessary to cap-ture the essential stiffness

response observed in the laboratory. The simplest such 'models' for

viscoelastic behavior combine a single spring and a single dashpot either in

series or in parallel. The corresponding 'Maxwell Model' and 'Kelvin Model' are

shown in Figures 3.4 and 3.5. In general a separate model may be necessary to

depict the observed isotropic and deviatoric behav-ior. This is true, for

example, in saturated clays where the volumetric behavior is well represented

by a Kelvin model and the deviatoric response by the Maxwell model. The

viscoelastic deformation of most solids, however, exhibits much more flow under

shear than mean stress. Thus we will discuss the various vis-coelastic models

in terms of deviatoric stress and the corresponding distor-tional strain,

recognizing that similar models can apply to volumetric behavior

with ![]() m,

m, ![]() m,

3K, and 3

m,

3K, and 3![]() substituted in place

of Sij, eij, 2G, and 2

substituted in place

of Sij, eij, 2G, and 2![]() .

.

Since in this book we consider only static loads,

the viscoelastic creep (and relaxation) behavior of our models is of primary

importance. For many struc-tures, particularly large ones like bridges or the

foundations on which they sit, the major part of the stress field in service is

due to constant 'dead' loads

anyway. Moreover, even

when live loads from wind, temperature changes, earthquakes, or traffic are

significant and generate important stress fields, little viscous flow will

occur since dashpots cannot react to sudden loads of short duration.* Thus, it

is generally a reasonable engineering assumption for viscoelastic solids to

calculate live-load stresses from the purely elastic response of the material

and the viscous strains from the dead-load part of the stress field neglecting

the comparatively transitory effects.**

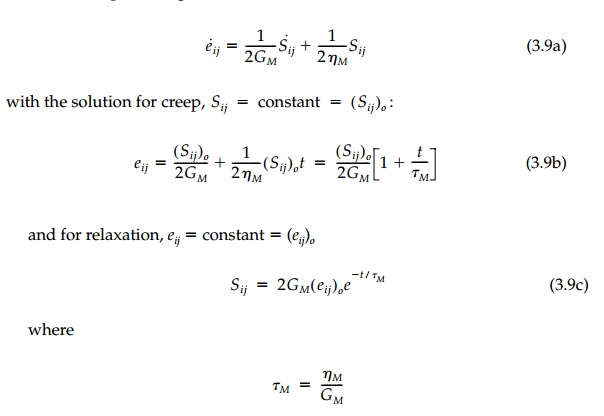

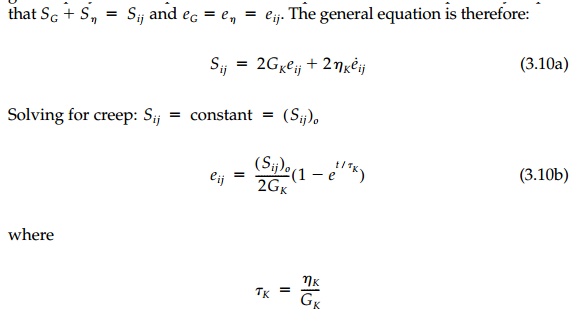

The creep curves for the Maxwell and Kelvin models

are shown in Figures 3.4 and 3.5. In each case the derivation of the

fundamental stress-strain equation from equilibrium and compatibility is

straightforward. For the Maxwell model with the spring and dashpot in series,

the stress in each component equals the total applied stress, Sij,

and the total deviatoric strain is the sum of that in each. Therefore, the

general equation for the deviatoric Maxwell model is

As can be seen in

Figure 3.4, the Maxwell model is essentially a fluid. Although it responds

elastically and appears to be solid, it flows indefi-nitely under sustained

stress. Silly putty is a perfect example of such a material.

The Kelvin* model where the components are in

parallel (Figure 3.5) is, on the other hand, a solid with the dashpot only

serving to delay the elastic response. In this case the stress in each

component depends on time with the dashpot taking all the stress at t =

0 and the spring only able to accept the stress given up by the dashpot as it

strains. Equilibrium and compatibility require

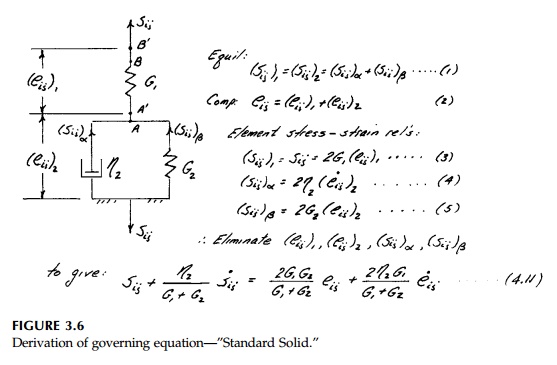

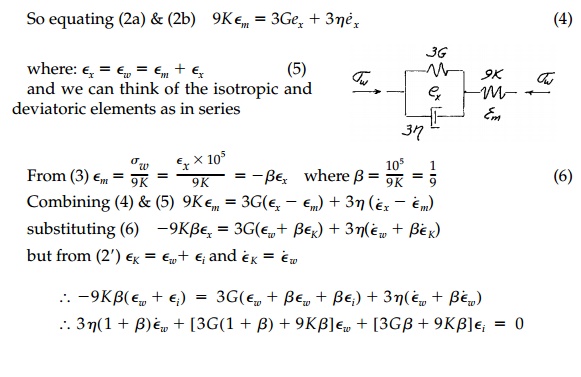

More complicated models can be developed to depict

viscoelastic behavior to any degree of sophistication. To illustrate the

procedure for determining the basic equations for such hybrid models, the

derivation for the 'standard solid' is shown as an example in Figure 3.6 while

others are left for home-work problems.

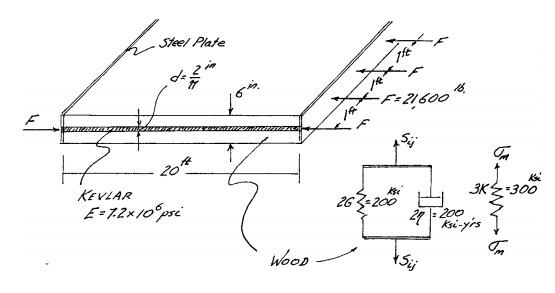

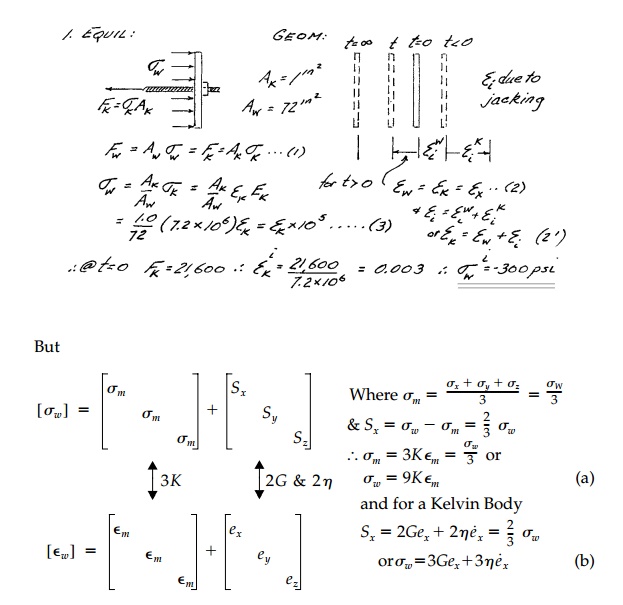

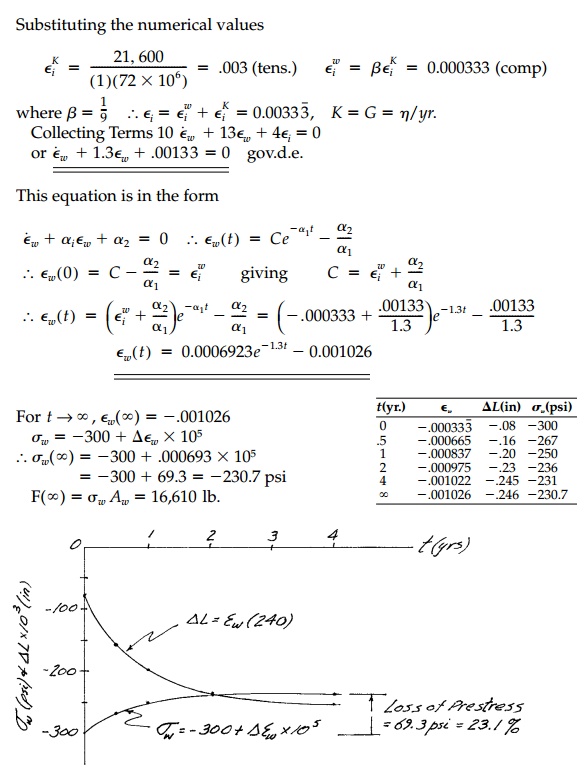

Example 3.2

A six-inch thick wooden

bridge deck is post-tensioned with 1 in.2 Kevlar tendons with a 1 ft

spacing jacked to an initial prestressing force F 21,600 lb as shown.

Kevlar can be considered elastic ( E=7.2 x

106 psi), but wood might be an elastic material in isotropic stress

and a Kelvin material in deviatoric stress with properties as shown.

Calculate and plot the stress in the wood and the

change in length ![]() L

as a function of time.

L

as a function of time.

Note:

a)We

are concerned only with stress and strain in x direction.

Assume both wood and Kevlar are free to expand in y

and z directions.

Related Topics