Chapter: Modern Analytical Chemistry: Developing a Standard Method

Verifying the Method

Verifying the Method

After developing and optimizing a method, it is necessary

to determine the quality

of results that can reasonably be expected when

the method is used by a single

ana- lyst. Generally, three steps are included in the process

of verifying a method: deter- mining single-operator characteristics, the blind analysis

of standards, and deter-

mining the method’s ruggedness. In addition, if an alternative standard method exists,

both the standard

method and the new method

can be used to analyze

the same sample, and

the results compared. If the quality

of the results

is unacceptable, the method

is not suitable for consideration as a standard

method.

Single-Operator Characteristics

The first step in verifying a method is to determine the precision, accuracy, and de- tection limit

when a single analyst uses the method

to analyze a standard sample

of known composition. The detection limit,

which was discussed, is de- termined by analyzing a reagent blank

for each type of sample

matrix for which

the method will be used. Precision is determined by analyzing replicate portions,

preferably more than ten, of a standard

sample. Finding the method’s accuracy

is evaluated by a t-test.

Precision and accuracy

should be evaluated for several different concentration levels of analyte, including at least one concentration near the detection

limit, and for each type of sample matrix that will

be encountered. The analysis of several concentrations allows for the detection of constant sources of determinate error and establishes the range of concentrations

for which the method is applicable.

Blind Analysis of Standard Samples

Single-operator characteristics are determined by analyzing a sample whose

concen- tration of analyte

is known to the analyst. The second step

in verifying a method is the blind analysis of standard samples where the analyte’s

concentration remains unknown to the analyst. The standard sample

is analyzed several

times, and the

av- erage concentration of the analyte

is determined. This value should

be within three, and preferably two standard deviations (as determined from the single-operator characteristics) of the analyte’s known

concentration.

Ruggedness Testing

In many cases

an optimized method

may produce excellent results in the laboratory

developing the method,

but poor results

in other laboratories. This is not

surprising since a method

is often optimized by a single

analyst under an ideal set

of condi- tions, in which the

sources of reagents, equipment, and instrumentation remain the same for each trial. The procedure

might also be influenced by environmental fac- tors, such as the

temperature or relative humidity in the

laboratory, whose levels

are not specified in the procedure and which may differ between

laboratories. Finally, when optimizing a method the analyst usually

takes particular care to perform

the analysis in exactly

the same way during every trial.

An important step in developing a standard method

is to determine which fac- tors have a pronounced effect on the quality of the analytical method’s result. The procedure can then be written to specify the degree to which these

factors must be controlled. A procedure that,

when carefully followed, produces high-quality results in different laboratories is considered rugged.

The method by which the critical fac- tors are discovered is called ruggedness testing.

Ruggedness testing is often performed by the laboratory

developing the stan- dard method.

Potential factors are

identified and their

effects evaluated by perform-

ing the analysis while the

factors are held

at two levels.

Normally one level

for each factor is that given

in the procedure, and the other is a level

likely to be encountered

when the procedure is used by other

laboratories.

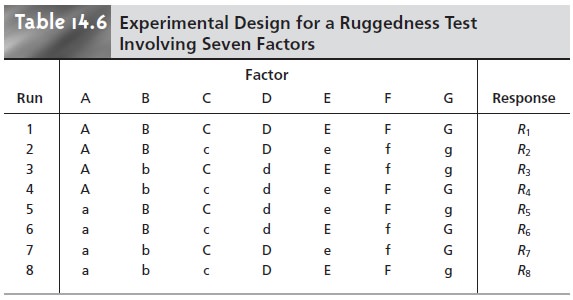

This approach to ruggedness testing can be time-consuming. If

seven poten- tial factors are identified, for example, ruggedness testing can be accomplished with a 27 factorial design. This requires

a total of 128 trials,

which is a prohibitively

large amount of work. A simpler experimental design is shown in Table 14.6, in which

the two factor

levels are identified by upper case and lower

case letters. This design,

which is similar

to that for the 23 factorial design discussed in the previous section, is called

a fractional factorial design and provides information about the first-order effect of each

factor. It does

not, however, provide

suffi- cient information to evaluate higher

order effects or potential interactions be- tween factors, both of which are assumed to be of less importance

than first- order effects.

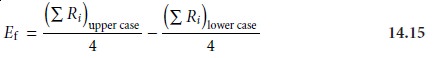

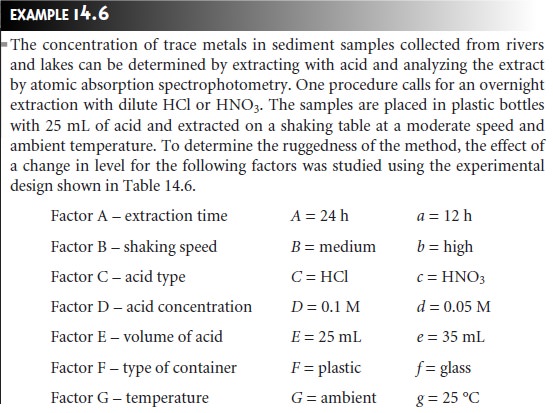

The experimental design for ruggedness testing is balanced in that each factor level is paired an equal number of times with the upper case and lower case levels for every other factor. The effect of changing the level for any one factor, Ef, is de- termined by subtracting the average response when the factor is at its upper case level from the average value when it is at its lower case level

Because

the design

is balanced, the levels for

the remaining factors

appear an equal number

of times in both summation terms, and, consequently, their effect on the response is canceled. For example, the effect of changing the level for fac-

tor A is determined by averaging the

responses from runs

1 through 4 and sub- tracting the average response

from runs 5 through 8. Factor B does not affect Ef

because its upper case levels

in runs 1 and 2 are canceled

by the upper case levels in runs 5 and 6, and its lower

case levels in runs 3 and 4 are canceled

by the lower case levels in runs 7 and 8. Similar reasoning shows that the remaining factors

are also canceled.

After each of the effects

is calculated, they are ranked

from largest to smallest,

without regard to sign, and those factors

whose effects are substantially larger

than the other factors

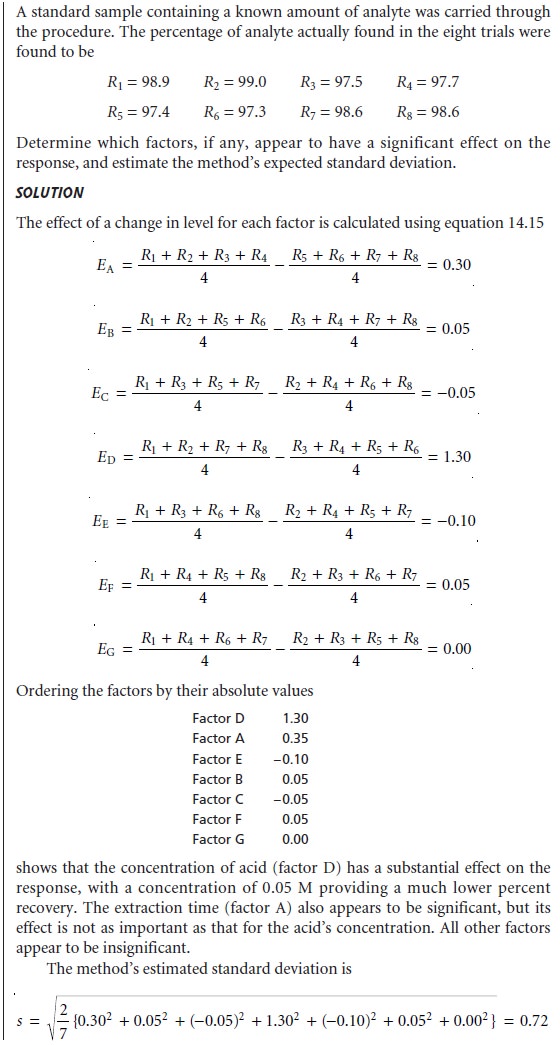

are identified. The estimated standard

deviation for the analysis is given

by

This provides the best estimate

of the expected standard deviation for results ob- tained by several laboratories, due to the effects of small changes

in uncontrolled or poorly controlled factors. If this standard

deviation is unacceptably large, then the procedure may be modified

to bring under

greater control those

factors whose lev- els

have the greatest

effect on the response.

Equivalency Testing

If a standard method is available, the performance of a new

method can be evalu-

ated by comparing results with those obtained

with an approved standard method. The comparison should be done at a minimum

of three concentrations to evaluate the applicability of the new method for different amounts

of analyte. Alternatively, we can plot the

results obtained by the new

method against those

obtained by the approved standard method. A linear regression analysis should give

a slope of 1 and a

y-intercept of 0 if the results

of the two methods are equivalent.

Related Topics