Chapter: Modern Analytical Chemistry: Developing a Standard Method

Mathematical Models of Response Surfaces

Mathematical Models of Response Surfaces

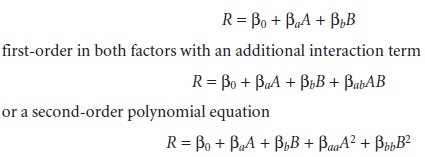

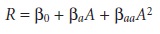

Earlier we noted that a response surface can be described mathematically by an equation relating the response to its factors. If a series of experiments is carried out in which we measure the response for several combinations of factor levels, then lin- ear regression can be used to fit an equation describing the response surface to the data. The calculations for a linear regression when the system is first-order in one factor (a straight line). A complete mathematical treat- ment of linear regression for systems that are second-order or that contain more than one factor is beyond the scope of this text. Nevertheless, the computations for a few special cases are straightforward and are considered in this section.

Theoretical Models of the Response Surface

Mathematical models

for response surfaces are divided into two categories: those based on theory and those that are

empirical. Theoretical models are

derived from known chemical and physical rela- tionships between the response and the factors. In spectrophotometry, for

example, Beer’s law is a theoretical model relating a substance’s absorbance, A, to its concen- tration, CA

A = εbCA

where ε is the molar absorptivity, and b is the pathlength of the electromagnetic ra- diation through the sample. A Beer’s law calibration curve,

therefore, is a theoretical

model of a response surface.

Empirical Models of the Response Surface

In many cases the underlying theoreti- cal relationship between the response

and its factors

is unknown, making

impossi- ble a theoretical model of the response surface.

A model can still be developed if we

make some reasonable assumptions about

the equation describing the response sur- face. For example, a response surface

for two factors, A and B, might be represented

by an equation that is first-order in both factors

The terms β0, βa, βb, βab,

βaa,and βbb, are

adjustable parameters whose

values are de- termined by using linear regression to fit the data to the equation.

Such equations are empirical models

of the response surface because they

have no basis

in a theo- retical understanding of the relationship between the response

and its factors. An empirical model

may provide an excellent description of the response

surface over a wide

range of factor

levels. It is more common,

however, to find

that an empirical model only applies to the range

of factor levels

for which data have been collected.

To develop an empirical model

for a response surface, it is necessary to collect the right

data using an appropriate experimental design. Two popular

experimental designs are considered in the following sections.

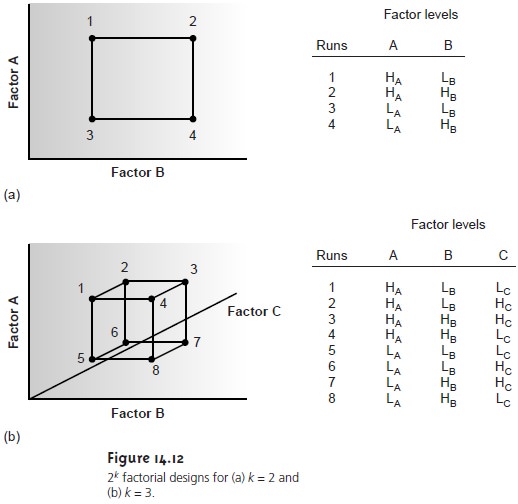

Factorial Designs

To determine a factor’s effect

on the response, it is necessary to measure the response for at least

two factor levels.

For convenience these

levels are labeled high,

Hf, and low, Lf, where

f is the factor; thus HA is the high level for factor

A, and LB is the low

level for factor

B. When more

than one factor

is included in the

empirical model, then each factor’s

high level should

be paired with both the high

and low levels for all other factors.

In the same way, the low level

for each factor should be paired with the high and low levels for all other factors (Figure

14.12). All together, a minimum of 2k experiments is necessary, where k is the number of fac-

tors. This experimental design is known as a 2k factorial design.

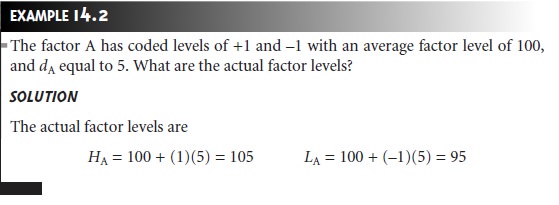

|

f |

value, xf,

is given as

xf = cf + d fxf* …………..14.3

where cf is the factor’s

average level, and df is the absolute

difference between the factor’s average level and its high and low values. Equation

14.3 is used to transform coded results back to their actual

values.

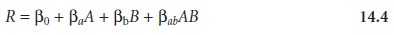

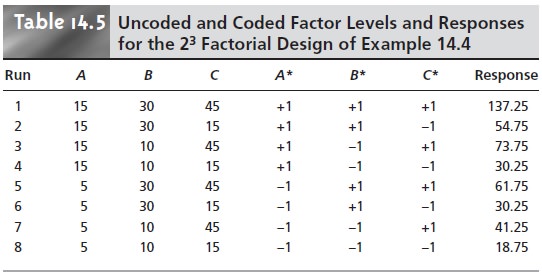

Let’s start by considering a simple example

involving two factors,

A and B, to which we wish to fit the following empirical model.

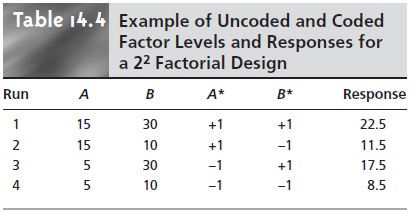

A 2k factorial design

with two factors

requires four runs,

or sets of experimental

conditions, for which the uncoded

levels, coded levels,

and responses are shown in Table

14.4. The terms

β0, βa, βb, and

βab in

equation 14.4 account

for, respectively, the mean effect (which

is the average response), first-order effects due to factors A and B, and the interaction between the two factors. Estimates

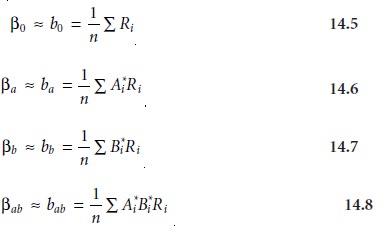

for these parameters are given by the following equations

where n is the number

of runs, and A* and B* are

the coded factor levels for the ithrun.

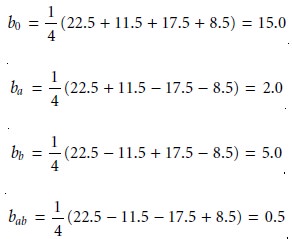

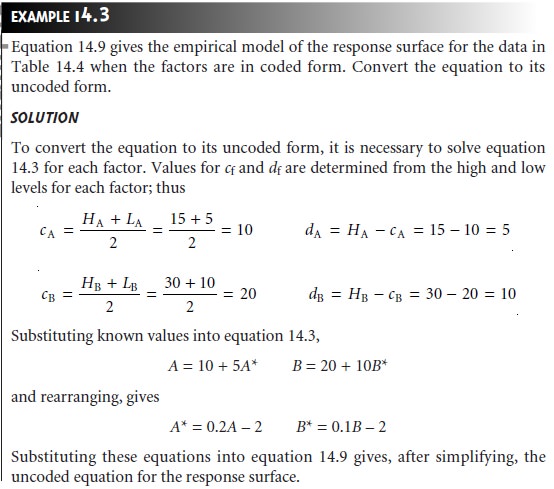

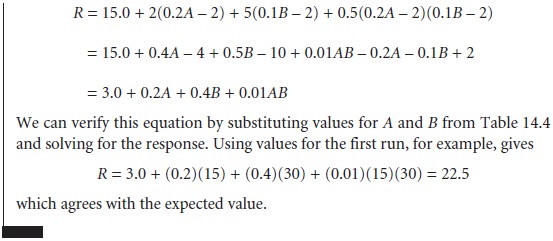

Solving for the estimated parameters using the data in Table 14.4

leaves us with the following empirical model for the response

surface

R =

15.0 + 2.0A* + 5.0B* + 0.5A*B* …………..14.9

The suitability of this model

can be evaluated by substituting values

for A* and B*

from Table 14.4 and comparing the calculated response to the known

response. Using the values for the first run as an example

gives

R = 15.0 + (2.0)(+1) + (5.0)(+1) + (0.5)(+1)(+1) = 22.5

which agrees with the known response.

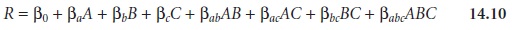

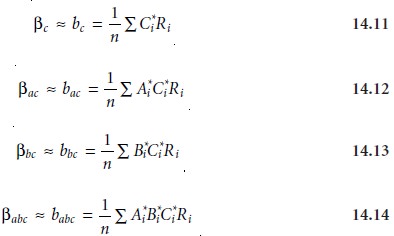

The computation just outlined is easily extended

to any number of factors.

For a system with three factors,

for example, a 23 factorial design can be used to deter-

mine the parameters for the

empirical model described by the following equation

where A, B, and

C

are the factors. The terms β0, βa, βb and βab

are estimated using equations 14.6–14.9. The remaining

parameters are estimated

using the following equations.

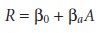

A 2k factorial design is limited

to models that include only a factor’s

first-order effects on the response. Thus,

for a 22 factorial design, it is possible to determine the first-order effect for each factor (βa and

βb), as well as the interaction between the factors

(βab). There is insufficient information in the factorial design, however, to determine any higher order

effects or interactions. This limitation is a consequence of having only two

levels for each

factor. Consider, for

example, a system

in which the response is a function of a single

factor. Figure 14.13a

shows the experimentally measured response

for a 21 factorial design in which

only two levels

of the factor are used. The

only empirical model

that can be fit to the data

is that for

a straight line.

If the actual

response is that represented by the dashed

curve, then the empirical

model is in error. To fit an empirical model

that includes curvature, a minimum of three levels must be included for each factor.

The 31

factorial design shown

in Fig- ure 14.13b,

for example, can

be fit to an empirical model that includes second-order effects for the factor.

In general, an n-level

factorial design can include single-factor and interaction terms up to the (n – 1)th order.

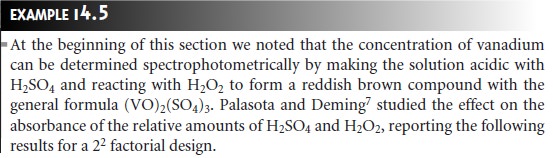

The effectiveness of a first-order empirical model can be judged

by measuring the response

at the center of the factorial design.

If there are no higher

order effects, the average

response of the runs in a 2k factorial design

should be equal

to the mea- sured response at the center

of the factorial design. The influence of random error can be accounted for

by making several

determinations of the

response at the

center of the factorial

design and establishing a suitable confidence interval. If the differ-

ence between the two responses

is significant, then a first-order empirical model is probably not appropriate.

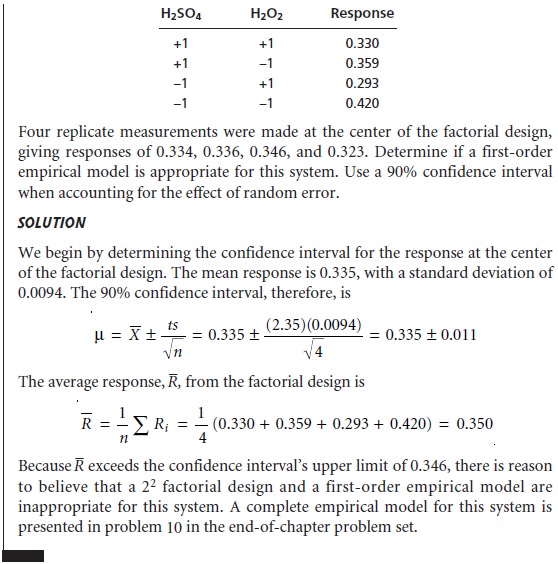

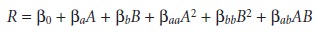

Many systems that cannot be represented by a first-order empirical model can be

described by a full second-order polynomial equation, such as that for two factors.

Because each factor

must be measured for at least

three levels, a convenient experi- mental design is a 3k factorial design.

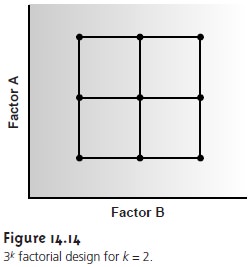

A 32

factorial design for two factors,

for exam- ple, is shown in Figure 14.14.

The computations for 3k factorial designs

are not as easily generalized as those

for a 2k

factorial design and

are not considered in this text.

Central Composite Designs

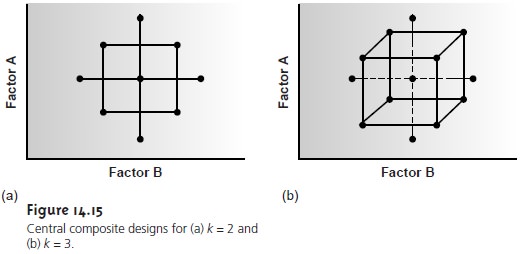

One limitation to a 3k factorial design is the number of trials that must be run. For two factors, as shown in Figure 14.14, a total of nine trials is needed. This number increases to 27 for three factors and 81 for four factors. A more efficient experimental design for systems containing more than two factors is the central composite design, two examples of which are shown in Figure 14.15. The central composite design consists of a 2k factorial de- sign, which provides data for estimating the first-order effects for each factor and interactions between the factors, and a “star” design consisting of 2k + 1 points, which provides data for estimating second-order effect. Although a central com- posite design for two factors requires the same number of trials, 9, as a 32 facto- rial design, it requires only 15 trials and 25 trials, respectively, for systems involving three or four factors. A discussion of central composite designs, includ- ing computational considerations.

Related Topics