Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Modern Methods of Railway Track Maintenance

Through MSP(Measured Shovel Packing) of Flat Bottomed Sleeper Tracks

Through MSP of Flat Bottomed Sleeper Tracks

MSP has been found to be very suitable for flat-bottomed sleepers, particularly wooden ones. About 33% of the running track on Indian Railways is on wooden sleepers and MSP can only be done on this length. The sequential description of this procedure is given in the following paragraphs.

Measurements of voids A sleeper is assessed to see whether it is fully packed or not. If not, the extent of the existence of packing voids is determined with the help of a canne-a-boule.

Fixation of high points The high points are then marked on each rail with the naked eye. At these high points, the cross levels are measured accurately up to 1 mm using a gauge-cum-level and any cross level errors are then corrected. These high points are called 'PH points' as per French terminology. These are normally spaced not more than 25 m apart.

Converting high points to good points The track is normally given a general lift of 10 mm for the first round of MSP and 5 mm for the second round of MSP, so that packing under the sleepers may be done effectively. New points, referred to as good points (or 'PB points'), are then marked on both the rails. For a higher rail, the PB value will be equal to the value of the general lift, i.e., 10 mm as a result of the first MSP, and for the lower rail, it will be equal to the sum of the value of the general lift and the cross level.

Longitudinal leveling Longitudinal levels are then measured between two high points on every alternate sleeper with the help of a viseur and a mire. The readings on intermediate sleepers are obtained by interpolation.

Total lift The total lift is calculated by adding the value of the voids assessed in the packing to the amount of lift discerned as per the requirement of the longitudinal levels. This value is called 'mark definitive' and is marked on the inside of the foot of the rail.

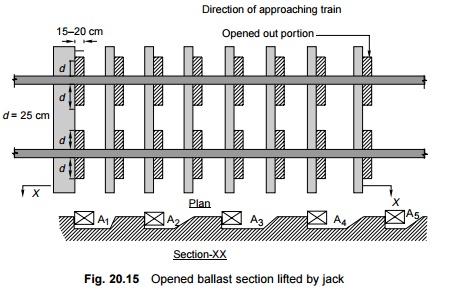

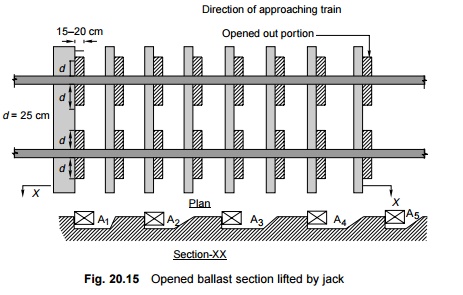

Opening out of ballast The ballast section is then opened out with the help of ballast rakes or special types of beaters as shown in (Fig. 20.15).

Lifting and packing of tracks Normally, a party of nine men is required for lifting and packing a track. The track is lifted with the help of non-infringing jacks. These jacks are placed nine sleepers apart on an evenly made up ballast bed. Not more than 4 cm of track should be lifted at a time to ensure that bigger ballast pieces do not roll in under the sleeper. The track is packed with the help of a special packing shovel. Depending upon the amount of voids present and the lifting done, the required quantity of small-sized stone chips is picked up by means of a dosing shovel from the wheelbarrow. For the first round of MSP, the quantity of chips required is about 3 m3 for 250/300 sleepers on BG/MG lines with a general lift measuring 10 mm and for the second and subsequent rounds of MSP it is 3 m3 for 1000/1250 sleepers on BG/MG lines with a general lift equal to or less than 5 mm. About 2.0, 1.5, or 1.0 m3 of chips are required for the MSP of one turnout of 1 in 16, 1 in 12, and 1 in 81/2, respectively.

Provision of ramps Ramps are provided to gradually ease off the difference in the longitudinal levels of the track between the portion of the track that has been attended to and the portion that is yet to be attended to. The provision of such ramps becomes necessary either in the case of an approaching train or at the end of a day's work. A provisional ramp of 3 mm per sleeper is provided in the face of approaching trains, whereas a ramp of 1 mm per sleeper is provided at the end of a day's work.

Alignment After correcting the longitudinal and cross levels of the track, the alignment is checked with the help of a viseur and a mire, using the vertical line on the rear side of the mire as a target. The use of guides is very important when alinging tracks, as the guides ensure that the viseur and mire are undisturbed while slewing is in progress.

Boxing and dressing of ballast After the surfacing and alignment of the track has been taken case of, the removed ballast is put back in the track by means of ballast rakes and the ballast section is boxed and dressed properly.

Majoration of joints Joints are checked for a second time on the following day and if any low joints are discovered, they are attended to. This second attention that is paid to the joints is technically called majoration of joints.

Checking of work done The cross levels and the longitudinal levels of the portion of the track that has already been attended to are checked after the passage of two trains. The variation in the cross level should not be more than 3 mm at any sleeper and the variation from sleeper to sleeper should not exceed 1 mm.

Related Topics