Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Modern Methods of Railway Track Maintenance

Measured Shovel Packing

Measured Shovel Packing

Measured shovel packing (MSP) is

an improved form of manual packing, which aims to provide a scientific method

of track maintenance that does not use any sophisticated mechanical aid. This

method, which was perfected on SNCF (French Railways) about 40 years ago, was

the standard method of track maintenance in the UK prior to the introduction of

mechanical maintenance. Even today, tracks on SNCF are mostly maintained by

MSP. This method makes it possible to maintain fish-plated and LWR tracks for

speeds of up to 160 km/h in these countries. As such, this method has the

potential of being used as a standard method of maintenance for high-speed

routes, particularly for flat-bottomed sleepers. It is definitely an asset for

controlling the overall economy by way of direct savings in labour and

maintenance of the track, and long-term savings in terms of longer life of

rails, sleepers, and fastenings due to improved track maintenance.

1 Essentials of MSP

MSP essentially consists of

taking accurate measurements of track defects, particularly of any existing

unevenness and voids, caused in the course of service and attending to the same

by placing a measured quantity of small-sized stone chips under the sleeper to

bring the track levels to their predetermined state. The compaction of these

stone chips occurs as a consequence of the passage of traffic. The extent to

which the track is required to be lifted is calculated by measuring the

longitudinal unevenness in the track once the cross levels and the voids under

the sleepers have been corrected. The longitudinal levels are measured with the

help of two optical instruments-the viseur and the mire-while the voids

under the sleeper bed are assessed by a ball-ended rod called canne-a-boule

and checked with the help of a mechanical device called the dansometer.

The track is lifted by 40 mm by means of special types of non-infringing jacks,

and a measured quantity of stone chips is then placed in the sleeper bed with

the help of a particular type of packing shovel. The jacks are then tripped off

and the alignment is finally corrected.

2 Scope of MSP

The process of MSP is suitable for the following types of

work.

(a) Through

packing of flat-bottomed sleepers

(b) Packing

of joint wooden sleepers in metal sleeper tracks

(c) Through

packing of points and crossings with wooden and steel sleepers

(d) Dehogging

of rail ends

3 Advantages and Disadvantages of MSP

Even though MSP is an excellent

method of track maintenance, it does have its drawbacks. The following are the

advantages and disadvantages of MSP.

Advantages of MSP

(a) The work

carried out is precise, wherein the track is worked upon as close to the

tolerances as possible because of the finer adjustments that are permissible in

MSP.

(b) The

retentivity of packing, particularly for joint sleepers, is more in the case of

MSP as compared to other modes of maintenance.

(c) MSP gives

increased output per gangman and is, therefore, economical.

(d) A minimum

clean ballast cushion is not needed when work is done through MSP.

(e) MSP does

not require any traffic blocks.

(f) MSP does

not damage the undersides of wooden sleepers, which are otherwise damaged in

manual methods of maintenance.

(g) MSP is

less strenuous and labourers do not shirk in doing the required work.

(h) The

gangman and the supervisory staff are able to pick up the uncomplicated

technique with very little training and experience.

Disadvantages of MSP

(a) Normally,

MSP can be done only in the case of flat-bottomed sleepers and this puts a

severe limitation on the scope of its application.

(b) This

procedure requires special size stone chips, which may not be easily available.

(c) MSP is

not effective in maintaining newly screened tracks. A consolidated bed is a

prerequisite for maintaining a track by means of MSP.

(d) MSP makes

use of delicate instruments and devices that can get damaged easily.

(e) Although

MSP is not a complicated process, it still requires a certain amount of skill,

for which the labourers have to be educated and trained.

4 Equipment Used in MSP

Special types of equipment are

used to carry out MSP. A brief description of each of these instruments is

given in the following paragraphs.

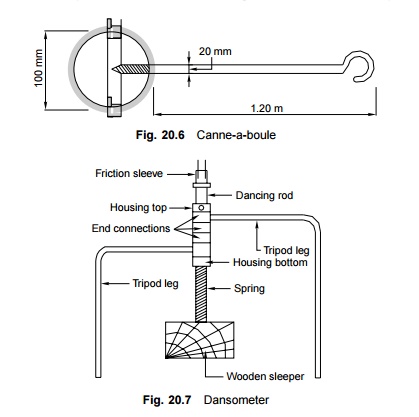

Canne-a-boule

A canne-a-boule is used for

assessing the extent of voids in the packing under the sleepers. In the case of

wooden sleepers, it consists of an iron ball of a diameter of 100 mm with a

1.20-m-long mild steel rod handle that has a diameter of 20 mm (Fig. 20.6). In

the case of steel trough sleepers, a 1.20-m-long wooden canne-a-boule is used

with a cylindrical wooden block that is 155 mm long and has a diameter of 100

mm. The canne-a-boule is dropped from a height of 40 cm at both ends of the

sleeper. The height of the rebound and the sound emitted in the process

determines the extent of the existence of packing voids. A value of 'zero' is

given to a sleeper that gives a good rebound and produces a solid sound. The

values increase as the sound gets dull and the rebound decreases.

Dansometer

A dansometer is used for

measuring the voids in the packing under the sleeper ends. The tripod legs

(Fig. 20.7) are fixed in the ballast bed while the dancing rod rests on the

sleeper. The extent to which the friction sleeve can shift from its original

position helps in determining the presence of voids under the sleeper in

dynamic conditions.

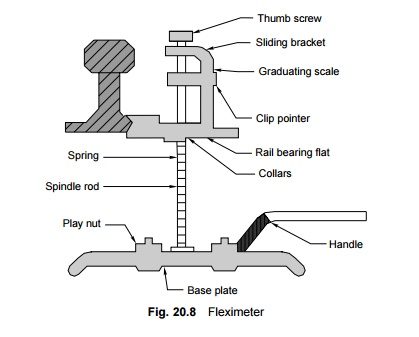

Fleximeter

A fleximeter is used to measure

the depression of the rail under the weight of plying traffic. It determines

the degree to which voids occur in the packing together with the play in the

fastenings, i.e., the gap between the rail foot and the sleeper. It is used in

conjunction with the dansometer to check the tightness of fastenings.

The difference between the

fleximeter and dansometer readings indicates the extent to which the fittings

between the rail and the sleeper have become loose (Fig. 20.8).

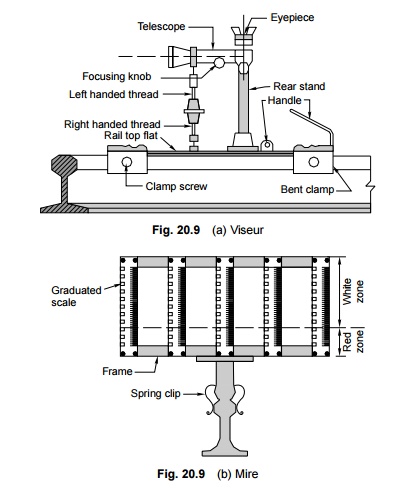

Viseur and mire

The viseur and mire are used to

measure the unevenness of the tail top and for rectifying the alignment. The

viseur is a type of telescope that has a magnifying power of about 12 and is

supported on a stand which can be fixed to the rail seat with the help of two

clamps [Fig. 20.9(a)]. The mire is a staff bearing five graduated scales, in

millimetres. It has a supporting frame that can be fixed to the rail head by

means of bent clamps [Fig. 20.9(b)].

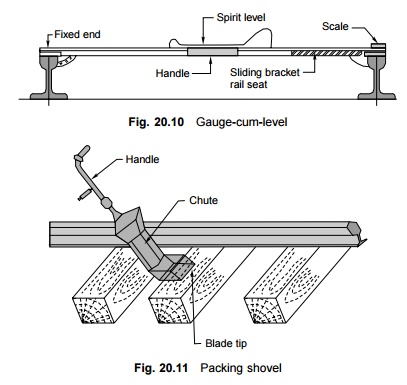

Gauge-cum-level

The gauge-cum-level is used for

measuring the gauge of the track as well as the cross levels (Fig. 20.10). The

cross level is measured with the help of an approximately 200-mm-long sensitive

spirit level with a sensitivity of 2' 30". The cross level can be measured

to an accuracy of 1 mm with the help of this instrument.

Packing shovel

A packing shovel is used for

placing stone chips over the full width of the sleeper under the rail seat. It

is about 1 m long and has a pan for collecting the chips under the sleeper bed.

The throw of the blade is 100 mm for BG lines and 85 mm for MG lines (Fig.

20.11).

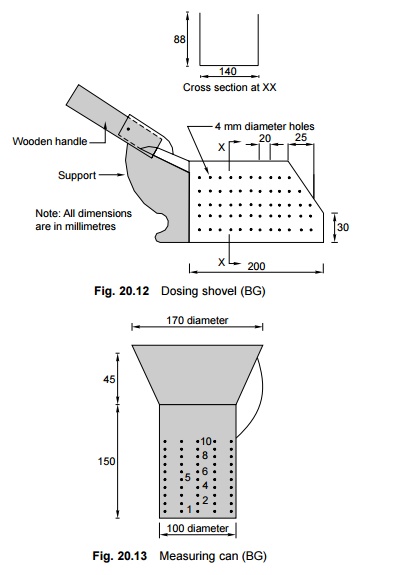

Dosing shovel

A dosing shovel is used for

picking up a measured quantity of stone chips for packing. This shovel has a

series of holes at different levels. By picking up chips to a specified height

in the shovel (Fig. 20.12), the quantity of the chips can be measured.

Measuring can

A measuring can is used to check

the accuracy of the dosing shovel. It is a cylindrical container of a height of

150 mm for BG lines and 120 mm for MG lines, with perforated holes at

calibrated intervals (Fig. 20.13).

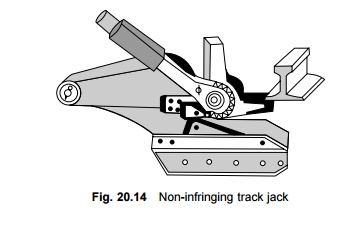

Non-infringing track jacks

Non-infringing track jacks (Fig.

20.14) are used for lifting the rail to a desired height. The jacks are

referred to as 'non-infringing' because the lifted rail can easily be returned

to its normal position in the case of an approaching train with little

manipulation and because they can be left on the track as none of their

components project above the rail level and infringe on movement. These jacks

are designed for a safe working load of 5 t and for a maximum lift of 200 mm

and 160 mm in the case of BG and MG lines, respectively.

5 Through MSP of Flat Bottomed Sleeper

Tracks

MSP has been found to be very

suitable for flat-bottomed sleepers, particularly wooden ones. About 33% of the

running track on Indian Railways is on wooden sleepers and MSP can only be done

on this length. The sequential description of this procedure is given in the

following paragraphs.

Measurements of voids A sleeper

is assessed to see whether it is fully packed or not. If not, the extent

of the existence of packing voids is determined with the help of a

canne-a-boule.

Fixation of high points The high

points are then marked on each rail with the naked eye. At these high

points, the cross levels are measured accurately up to 1 mm using a

gauge-cum-level and any cross level errors are then corrected. These high

points are called 'PH points' as per French terminology. These are normally

spaced not more than 25 m apart.

Converting high points to good

points The track is normally given a general lift of 10 mm for

the first round of MSP and 5 mm for the second round of MSP, so that packing

under the sleepers may be done effectively. New points, referred to as good

points (or 'PB points'), are then marked on both the rails. For a higher rail,

the PB value will be equal to the value of the general lift, i.e., 10 mm as a

result of the first MSP, and for the lower rail, it will be equal to the sum of

the value of the general lift and the cross level.

Longitudinal leveling Longitudinal

levels are then measured between two high points on every alternate

sleeper with the help of a viseur and a mire. The readings on intermediate

sleepers are obtained by interpolation.

Total lift The total

lift is calculated by adding the value of the voids assessed in the

packing to the amount of lift discerned as per the requirement of the

longitudinal levels. This value is called 'mark definitive' and is marked on

the inside of the foot of the rail.

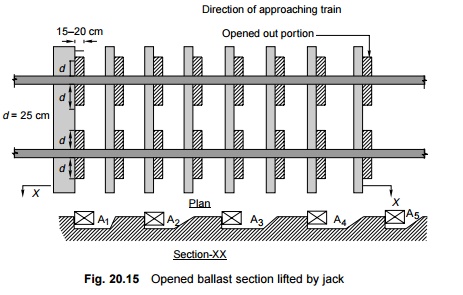

Opening out of ballast The

ballast section is then opened out with the help of ballast rakes or

special types of beaters as shown in (Fig. 20.15).

Lifting and packing of tracks Normally,

a party of nine men is required for lifting and packing a track. The

track is lifted with the help of non-infringing jacks. These jacks are placed

nine sleepers apart on an evenly made up ballast bed. Not more than 4 cm of

track should be lifted at a time to ensure that bigger ballast pieces do not

roll in under the sleeper. The track is packed with the help of a special

packing shovel. Depending upon the amount of voids present and the lifting

done, the required quantity of small-sized stone chips is picked up by means of

a dosing shovel from the wheelbarrow. For the first round of MSP, the quantity

of chips required is about 3 m3 for 250/300 sleepers on BG/MG lines

with a general lift measuring 10 mm and for the second and subsequent rounds of

MSP it is 3 m3 for 1000/1250 sleepers on BG/MG lines with a general

lift equal to or less than 5 mm. About 2.0, 1.5, or 1.0 m3 of chips

are required for the MSP of one turnout of 1 in 16, 1 in 12, and 1 in 81/2,

respectively.

Provision of ramps Ramps are

provided to gradually ease off the difference in the longitudinal levels

of the track between the portion of the track that has been attended to and the

portion that is yet to be attended to. The provision of such ramps becomes

necessary either in the case of an approaching train or at the end of a day's

work. A provisional ramp of 3 mm per sleeper is provided in the face of

approaching trains, whereas a ramp of 1 mm per sleeper is provided at the end

of a day's work.

Alignment After

correcting the longitudinal and cross levels of the track, the alignment

is checked with the help of a viseur and a mire, using the vertical line on the

rear side of the mire as a target. The use of guides is very important when

alinging tracks, as the guides ensure that the viseur and mire are undisturbed

while slewing is in progress.

Boxing and dressing of ballast After the

surfacing and alignment of the track has been taken case of, the removed

ballast is put back in the track by means of ballast rakes and the ballast section

is boxed and dressed properly.

Majoration of joints Joints

are checked for a second time on the following day and if any low joints

are discovered, they are attended to. This second attention that is paid to the

joints is technically called majoration of joints.

Checking of work done The cross

levels and the longitudinal levels of the portion of the track that has

already been attended to are checked after the passage of two trains. The

variation in the cross level should not be more than 3 mm at any sleeper and

the variation from sleeper to sleeper should not exceed 1 mm.

6 MSP of Joint Wooden

Sleepers on Metal Sleeper Track

A joint is the weakest link in

the track and special attention has to be paid towards its maintenance. The

maintenance of joint sleepers is not very effective in the case of the

conventional beater packing method because of the close spacing of the sleepers

at the joint. The loosening of the packing at the joints results in a number of

maintenance problems. MSP has been found to be very effective for packing joint

wooden sleepers.

This method involves the usual

through beater packing of the intermediate sleepers followed by MSP of the

joint sleepers so as to bring the surface of the track to longitudinal and

cross levels consistent with that of metal sleeper tracks. A detailed account

of this procedure follows.

Calculation of total lift The total

lift required is calculated by evaluating the voids at the joint

sleepers and adding this value to the longitudinal lift required on account of

the general sag of the track. The total lift for the two rails is then assessed

as follows:

Total lift for sighting rail = longitudinal lift + voids under

the sighting rail Total lift for second rail = fleximeter reading on sighting

rail + voids under

the second rail + cross level difference at the joint

The cross levels are then

correctly noted with the help of an accurate gauge-cum-level.

Lifting and packing of joint

sleepers Joint sleepers are lifted to the required extent, but

not more than 40 mm by means of non-infringing jacks. The required quantity of

small stone chips are placed under the joint sleepers with the help of packing

shovels. The jacks are then released from their positions and the sleepers are

tamped with the help of blunt-ended crowbars so that they are evenly seated on

the layer of chips.

Alignment corrections General

alignment corrections are made while work is underway on the

intermediate sleepers by way of the conventional beater packing method. Any

disturbances that occur in the alignment during the MSP of joint sleepers are

subsequently corrected.

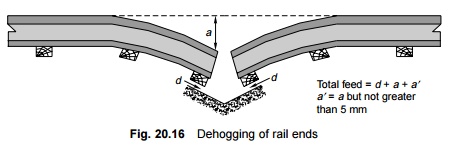

7 Dehogging of Rail Ends

Hogged rail ends can be dehogged

with the help of MSP in the following manner (Fig. 20.16).

1. The dip

at the joint sleeper (a) is measured by using a 1.5-m straight edge and

a feeler gauge at a distance of 50 mm from the rail end.

2. The dance

at the joint sleepers (d), which is the gap between the sleeper and the

ballast, is measured by a canne-a-boule or dansometer.

3. The joint

sleepers are lifted and packed to a value equal to d + a + a',

where

d is the value of dance, a is

the amount of dip, and a' is equal to a or 5 mm, whichever

is lower.

After allowing traffic to run on

the track for a period of two days, the adjoining sleepers are beater or shovel

packed depending upon whether it consists of metal or wooden sleepers. The

dehogging of rail ends is achieved because of the train loads. It may be

necessary to repeat this procedure in case the rails are not completely

dehogged.

8 MSP of Turnouts

The MSP of turnouts laid on

wooden sleepers is quite effective. This process involves the following steps.

Measurement of voids Voids in

the main line as well as on the turnout side are measured by a canne-a-boule.

Location of high points The high

points are then located using a gauge-cum-level and these are

marked on the stock rail.

Conversion of high points to good

points High points are converted into good points

on the stock rail.

Longitudinal levelling Longitudinal

levels on the stock rail are measured by means of a viseur and a

mire.

Total lift Total

lift is the sum of the number of packing voids and the difference in the

longitudinal levels.

Shovel packing The

ballast between sleepers is completely removed and the track is

lifted by using track jacks.

Putting back the ballast After

packing, the ballast is put back and the joints are tackled once

again, if necessary.

Alignment correction The main

line is aligned with the help of a viseur and a mire.

Attention to approaches Approaches

to the turnout are dealt with by means of MSP or beater packing

to adjust the longitudinal levels.

9 Organization of Labour for MSP

Proper organization of labour is

necessary for successfully implementing the MSP programme on Indian Railways.

Normally, a gang of 9 to 15 persons khalasis and one mate headed by a PWI grade

III are employed for carrying out various MSP works. A rough estimate of the

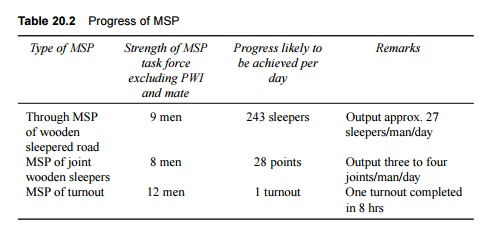

strength of the MSP task force is given in Table 20.2 along with the average

progress achieved by it.

20.5.10 Equipment Required

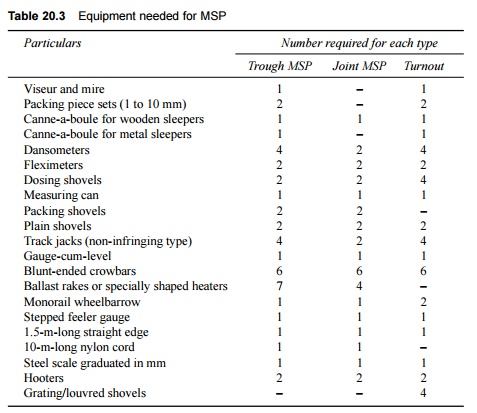

Table 20.3 lists the equipment

normally required for carrying out the MSP of different works.

Table 20.3 Equipment needed for MSP

11 Future of MSP on

Indian Railways

MSP, though introduced only

recently, has shown great potential for being used extensively on Indian

Railways. The method is simple but scientific. It provides a better and lasting

surface to the tracks and has also proved to be very beneficial to the economy.

The method is particularly suited to Indian conditions due to the abundance of

cheap labour and use of simple equipment manufactured indigenously. It was

earlier believed that the method was suitable only for flat-bottomed sleepers

such as wooden and concrete sleepers, but recent trials have proved that the

technique can be used for maintaining steel and CST-9 sleepers as well.

Related Topics