Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Modern Methods of Railway Track Maintenance

Mechanized Methods of Railway Track Maintenance

Mechanized Methods of Track Maintenance

The need to switch over from

manual to mechanized methods of track maintenance is progressively being felt

due to the following reasons.

(a) Beater

packing is a very hard and strenuous job and thus the labourers have a tendency

to shirk from doing this type of work.

(b) It is

difficult to ensure the uniform quality of the compaction under the sleepers

carried out by manual means due to the uncertainties associated with the

varying physical strength of the labourers, commitment of the workers, varying

weather conditions, and other allied factors.

(c) The

intensity of the pressure and shock that the ballast is subjected to when the

beater is being used is very high and in many cases exceeds the crushing

strength of the stone. This results in the progressive clogging of the ballast

section.

(d) Traffic

densities, axle loads, and speeds have increased considerably on Indian

Railways considerably in the recent past. Beater packing does not enable track

geometry to be maintained within the tolerances prescribed for a satisfactory

length of time.

(e) The

retention of the packing done via manual maintenance is not very good and the

track geometry gets distorted in a short time due to high-speed traffic.

(f) Manual

maintenance is not much suited to the modern track, which consists of long

welded rails and heavy concrete sleepers.

(g) With the

increase in traffic density, the time available between trains is becoming

progressively short. It is, therefore, becoming increasingly difficult to

maintain tracks by manual methods, which take a considerably long time.

(h) When a

track is maintained manually, it takes considerable time for it to get fully

consolidated and, therefore, speed restrictions exist for a long period after

track renewal work has been completed.

(i) Manual

methods do not emphasize on the identification of defects and monitoring of the

work being done. These are, however, done in the case of modern methods of

track maintenance, thereby giving move effective results.

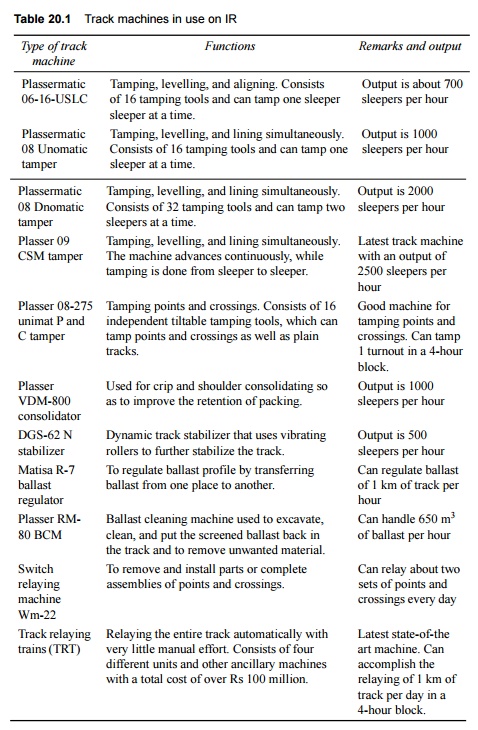

Some of the important heavy track

machines being used on Indian Railways (IR) are listed in Table 20.1.

Table 20.1 Track machines in use on

IR

On railways, the mechanized

maintenance of tracks normally involves the use of mechanical tampers, which

are used to tamp or pack the ballast. Mechanical tampers are generally of two

types, namely, off-track tamper and on-track tampers.

Related Topics