Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Modern Methods of Railway Track Maintenance

Railway: Off-Track Tampers: Use and Limitations

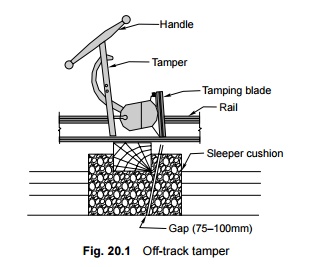

Off-Track Tampers

Off-track tampers are portable and can be quickly taken off

the track by just two people. These tampers work during the interval between

the passage of trains and do not require any traffic blockage (Fig. 20.1). They

consist of tools driven by compressed air, electricity, or petrol. There are

generally two types of tampers, namely, self-contained tampers and those that

are worked from a common power unit. Tampers may be vibratory or of the

percussion type or a combination of both. In the vibratory type, tamping is

achieved by vibration as well as by the weight of the tamper itself, while in

the percussion type. tamping is achieved by imparting blows. The important

off-track tampers tried on Indian Railways are Cobra tampers, Jackson tampers,

Shibaura tampers, and Kango tampers.

1 Use of Off-track Tampers

Off-track tampers are placed

diagonally under the rail and worked in pairs from the opposite sides of the

sleepers in order to ascertain the maximum consolidation of the ballast. Using

beaters, the ballast is first loosened around the rail seat in the crib for a

length of 450 mm (18") on either side of the foot of the raft. The tamper

is then inserted vertically and the tamping tool blades are kept about 75 to

100 mm away from the sleeper so that enough ballast is available between the

two as shown in Fig. 20.1. During its working, the head of the tamper should be

moved slightly backward in the shape of an arc of a circle so that the

surrounding ballast is well compacted. The operator should not exert force on

the tamper while tamping is being done using either the vibratory system or the

percussion system.

The average progress achieved by

one set of off-track tampers is about 3 km per month, after taking the repairs,

overhauling , etc. into consideration.

2 Limitations of Off-track Tampers

Off-track tampers have not been

much of a success on Indian Railways because of the following reasons.

(a) The

maintenance of these tampers has been found to be extremely difficult because

of the non-availability of spare parts, which are mostly imported.

(b) Transporting

off-track tampers along with their power units to the site of work in the

mid-section is quite problematic.

(c) Tamping

with off-track tampers is very strenuous and a worker normally gets fatigued

after 30-40 minutes. The quality of work done after this duration is likely to

deteriorate.

(d) Intensive

supervision is required to ensure the correct use of these tampers so that the

work done is of the desired quality. This type of supervision becomes

particularly difficult in the mid-section.

(e) The

quality of tracks maintained using tampers is not very high compared to those

maintained by manual methods.

(f) The use

of off-track tampers following deep screening and relaying work has been found

to be very unsuitable for the early restoration of normal

speed.

However, off-track tampers are

yet to be tried under the following conditions on Indian Railways.

(a) For

packing the points and crossings where normal packing cannot be done

effectively due to limited space.

(b) For packing newly realigned curves, on which the track requires immediate consolidation so that its alignment remains undisturbed and normal speed can be restored along its length as early as possible.

Related Topics