Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Modern Methods of Railway Track Maintenance

Directed Track Maintenance

Directed Track Maintenance

As the name suggests, directed

track maintenance (DTM) is a method of maintaining the track on the basis of

directions that are given in this regard every day, and not as a prescribed

routine. Directed track maintenance essentially consists of need-based

maintenance rather than routine maintenance. In the case of DTM, track

maintenance is done by proper identifying any defects in track geometry and

rectifying these defects by attending to the track at the affected locations

under close supervision, thereby maintaining the track at predetermined

standards.

1 Objectives

The two main objectives of DTM are as follows.

(a) To

maintain high standards of track maintenance as per predetermined tolerances.

(b) Reduction

in the cost of maintenance mainly by the avoidance of unnecessary work.

In order to achieve the desired

objectives, the following special features are incorporated in DTM vis-à-vis

the conventional system of maintenance.

(a) The level

of supervision is improved by hiring a well-trained and qualified permanent way

mistry.

(b) A

thorough record of the track defects identified before and after the completion

of work is maintained to assess the inputs and also to help devise remedial

measures of a more permanent nature by carrying out a scientific study based on

the assimilated facts.

(c) Increasing

the length of the unit especially on single lines increases the number of the

gangmen available, resulting in an improvement in the productivity of the gang

as well as the quality of work.

(d) The track

is aimed to be brought to a predetermined level of service tolerances.

2 Work Done Under DTM

The maintenance operations to be

carried out in a section where DTM has been introduced can be placed into the

following four categories.

(a) Systematic overhauling In DTM,

while the emphasis is on need-based maintenance, the intention is not to

completely dispense with routine maintenance works such as systematic

overhauling. Instead, the frequency of systematic overhauling is suitably

increased, say by three to four years or as decided by the chief engineer,

depending on local factors such as the condition of the track and the

formation, traffic density, permissible speed, and rainfall. A certain number

of working days in the appropriate months of the year are earmarked for this

work so as to cover one-third or one-fourth of the gang length by systematic

overhauling, depending on the site conditions.

(b)

Periodic maintenance work This

includes works such as the lubrication of joints, cleaning of side

drains, catch water drains, and repairs of the formation and cess. In the

annual program, an adequate number of working days should be set aside during

the appropriate months for periodic maintenance work.

(c)Occasional

maintenance work This includes other works such as scattered renewal

of rails, sleepers, and other track components, adjusting creep, restoring

correct spacing between sleepers, building damaged rail ends, realigning

curves, overhauling level crossings as well as points and crossings, and

properly removing any deficiencies in the ballast section. The permanent way

inspector assesses the quantum of such works that are to be carried out

periodically in the order of their priority and draws up a programme in

consultation with engineers after taking into consideration the availability of

track material, ballast, welding parties, etc.

(d) Need-based

maintenance The remaining working days in the annual programme

are devoted to need-based maintenance, which is a new concept and forms the

main distinguishing feature of DTM as compared to the conventional system of

maintenance. The operations involved in need-based maintenance are as follows.

(a) Location

of defects by analysing the results of the track recording car/ oscillograph

car/hallade recorder and by foot plate/rear vehicle/trolley/foot inspection.

(b) Identification

of defects by means of systematic inspection and by ground measurements taken

by trained supervisors using precision instruments.

(c) Recording

of the observations.

(d) Rectifying

track defects by attending only to the defective portion followed by a post

check of the same portion conducted by the supervisor to check its quality and

output.

3

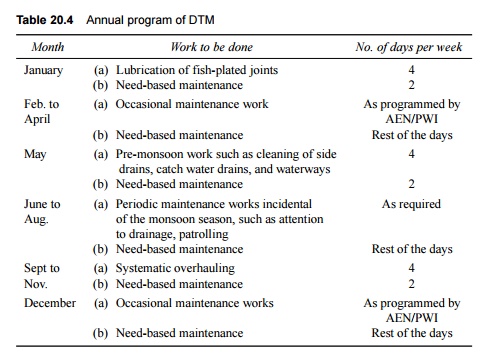

Annual Program for DTM

Table 20.4 depicts a typical chart showing the annual program

of track maintenance under DTM.

The following points need to be mentioned with

respect to the data given in Table 20.4.

(a) The chart

is only for guidance, and the chief engineers of zonal railways can make

variations to suit the local conditions.

The chart is for that section of

the track where manual methods of maintenance are adopted. Whenever maintenance

involves the use of machines, the DTM unit will assist in the same by taking

care of the work of pre-tamping and post-tamping and other operations not

covered by machines.

Table 20.4 Annual program of DTM

Related Topics