Chapter: Mechanical : Metrology and Measurements : Measurement of Power, Flow and Temperature Related Properties

Thermoresistive Temperature Measuring Devices

THERMORESISTIVE

TEMPERATURE MEASURING DEVICES

Principle of operation

·

A change in temperature causes the electrical

resistance of a material to change.

·

The resistance change is measured to

infer the temperature change.

·

There are two types of thermoresistive

measuring devices: resistance temperature detectors and thermistors, both of

which are described here.

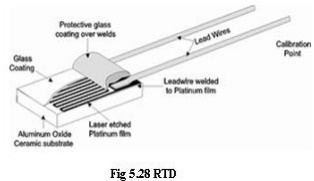

Resistance temperature detectors

A resistance temperature detector (abbreviated RTD)

is basically either a long, small diameter metal wire (usually platinum) wound

in a coil or an etched grid on a substrate, much like a strain gauge.

The resistance of an RTD increases with increasing

temperature, just as the resistance of a strain gage increases with increasing

strain. The resistance of the most common RTD is 100 Ω at 0ºC.

If the temperature

changes are large, or if precision is not critical, the RTD resistance can be

measured directly to obtain the temperature. If the temperature changes are

small, and/or high precision is needed, an electrical circuit is built to

measure a change in resistance of the RTD, which is then used to calculate a

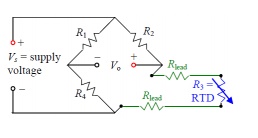

change in temperature. One simple circuit is the quarter bridge Wheatstone

bridge circuit, here called a two-wire RTD bridge circuit

Rlead

represents the resistance of one of the wires (called lead wires) that run from

the bridge to the RTD itself. Lead resistance is of little concern in strain

gage circuits because Rlead remains constant at all times, and we

can simply adjust one of the other resistors to zero the bridge.

For RTD circuits, however, some portions of the lead

wires are exposed to changing temperatures. Since the resistance of metal wire

changes with temperature, Rlead changes with T and this can cause

errors in the measurement. This error can be non-trivial changes in lead

resistance may be misinterpreted as changes in RTD resistance, and therefore

give a false temperature measurement.

Thermistors

A thermistor is similar

to an RTD, but a semiconductor material is used instead of a metal. A

thermistor is a solid state device. Resistance thermometry may be performed

using thermistors. Thermistors are many t useful over limited ranges of

temperature. They are small pieces of ceramic material made by sintering

mixtures of metallic oxides of Manganese, Nickel, Cobalt, Copper and Iron etc.

Resistance of a

thermistor decreases non-linearly with temperature. Thermistors are extremely

sensitive but over a narrow range of temperatures. A thermistor has larger

sensitivity than does an RTD, but the resistance change with temperature is

nonlinear, and therefore temperature must be calibrated with respect to

resistance. Unlike RTDs, the resistance of a thermistor decreases with

increasing temperature. The upper temperature limit of thermistors is typically

lower than that of RTD. However, thermistors have greater sensitivity and are

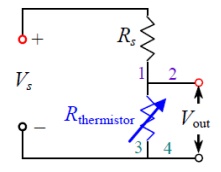

typically more accurate than RTDs or thermocouples. A simple voltage divider,

where Vs is the supply voltage and Rs is a fixed (supply) resistor. Rs and Vs

can be adjusted to obtain a desired range of output voltage Vout for a given

range of temperature. If the proper value of Rs is used, the output voltage is

nearly (but not exactly) linear with temperature. Some thermistors have 3 or 4

lead wires for convenience in wiring –two wires are connected to one side and

two to the other side of the thermistor (labeled 1, 2 and 3, 4 above).

Related Topics