Chapter: Mechanical : Metrology and Measurements : Measurement of Power, Flow and Temperature Related Properties

Rotameter

Rotameter

The orificemeter, Venturimeter and flow nozzle work on the principle of constant area variable pressure drop. Here the area of obstruction is constant, and the pressure drop changes with flow rate. On the other hand Rotameter works as a constant pressure drop variable area meter. It can be only be used in a vertical pipeline. Its accuracy is also less (2%) compared to other types of flow meters. But the major advantages of rotameter are, it is simple in construction, ready to install and the flow rate can be directly seen on a calibrated scale, without the help of any other device, e.g. differential pressure sensor etc. Moreover, it is useful for a wide range of variation of flow rates (10:1).

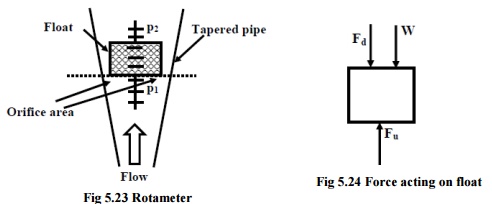

The basic construction of a rotameter is shown in figure. It consists of a vertical pipe, tapered downward. The flow passes from the bottom to the top. There is cylindrical type metallic float inside the tube. The fluid flows upward through the gap between the tube and the float. As the float moves up or down there is a change in the gap, as a result changing the area of the orifice. In fact, the float settles down at a position, where the pressure drop across the orifice will create an upward thrust that will balance the downward force due to the gravity. The position of the float is calibrated with the flow rate.

Fig 5.23 Rotameter

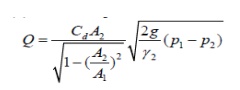

γ1= Specific weight of the float

γ2= specific weight of the fluid

ν= volume of the float

Af= Area of the float.

At= Area of the tube at equilibrium (corresponding to the dotted line)

Fd = Downward thrust on the float Fu = Upward thrust on the float

The major source of error in rotameter is due to the variation of density of the fluid. Besides, the presence of viscous force may also provide an additional force to the float.

Applications

· Can be used to measure flow rates of corrosive fluids

· Particularly useful to measure low flow rates

Advantages

· Flow conditions are visible

· Flow rate is a linear function(uniform flow scales)

· Can be used to measure flow rates of liquids, gases and vapour

· By changing the float, tapered tube or both, the capacity of the rotameter can be changed.

Limitations

· They should be installed vertically

· They cannot be used for measurements in moving objects

· The float will not be visible when coloured fluids are used, that is, when opaque fluid are used.

· For high pressure and temperature fluid flow measurements, they are expensive

· They cannot be used for fluids containing high percentage of solids in suspension.

Related Topics