Chapter: Mechanical : Metrology and Measurements : Measurement of Power, Flow and Temperature Related Properties

Flow Measurements

FLOW MEASUREMENTS

The flow rate of a fluid flowing in a

pipe under pressure is measured for a variety of applications, such as

monitoring of pipe flow rate and control of industrial processes. Differential

pressure flow meters, consisting of orifice, flow nozzle, and venturi meters,

are widely used for pipe flow measurement and are the topic of this course. All

three of these meters use a constriction in the path of the pipe flow and

measure the difference in pressure between the undisturbed flow and the flow

through the constriction. That pressure difference can then be used to

calculate the flow rate. Flow meter is a device

that measures the rate of flow or quantity

of a moving fluid in an open or closed conduit.

Flow measuring devices are generally classified into four groups.

They are

1. Mechanical type flow

meters

Fixed restriction variable

head type flow meters using different sensors like orifice plate, venturi tube,

flow nozzle, pitot tube, dall tube, quantity meters like positive displacement

meters, mass flow meters etc. fall under mechanical type flow meters.

2. Inferential type flow

meters

Variable area flow meters

(Rotameters), turbine flow meter, target flow meters etc.

3. Electrical type flow

meters

Electromagnetic flow

meter, Ultrasonic flow meter, Laser doppler Anemometers etc. fall under

electrical type flow meter.

4. Other flow meters

Purge flow regulators,

Flow meters for Solids flow measurement, Cross-correlation flow meter, Vortex

shedding flow meters, flow switches etc.

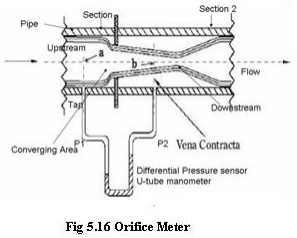

Orifice

Flow Meter

An Orifice flow meter is

the most common head type flow measuring device. An orifice plate is inserted

in the pipeline and the differential pressure across it is measured.

Principle of Operation

The orifice plate inserted in the

pipeline causes an increase in flow velocity and a corresponding decrease in

pressure. The flow pattern shows an effective decrease in cross section beyond

the orifice plate, with a maximum velocity and minimum pressure at the

venacontracta.

The flow pattern and the sharp leading

edge of the orifice plate which produces it are of major importance. The sharp

edge results in an almost pure line contact between the plate and the effective

flow, with the negligible fluid-to-metal friction drag at the boundary.

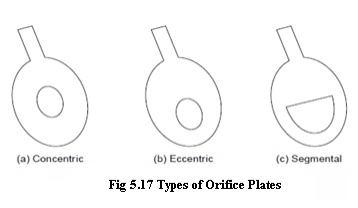

Types of Orifice Plates

The simplest form of

orifice plate consists of a thin metal sheet, having in it a square edged or a

sharp edged or round edged circular hole.

There are three types of orifice plates namely

1. Concentric

2. Eccentric and

3. Segmental type.

The concentric type is

used for clean fluids. In metering dirty fluids, slurries and fluids containing

solids, eccentric or segmental type is used in such a way that its lower edge

coincides with the inside bottom of the pipe. This allows the solids to flow

through without any obstruction. The orifice plate is inserted into the main

pipeline between adjacent flanges, the outside diameters of the plate being

turned to fit within the flange bolts. The flanges are either screwed or welded

to the pipes.

Applications

The concentric orifice plate is used

to measure flow rates of pure fluids and has a wide applicability as it has

been standardized

·

The eccentric and

segmental orifice plates are used to measure flow rates of fluids containing

suspended materials such as solids, oil mixed with water and wet steam.

Advantages

·

It is very cheap and easy

method to measure flow rate

·

It has predictable characteristics

and occupies less space

·

Can be used to measure

flow rates in large pipes

Limitations

· The vena-contracta length depends on the roughness of the inner

wall of the pipe and sharpness of the orifice plate. In certain case it becomes

difficult to tap the minimum pressure due the above factor

· Pressure recovery at downstream is poor, that is, overall loss

varies from 40 to 90% of the differential pressure.

· In the upstream straightening vanes are a must to obtain laminar

flow conditions.

· The orifice plate gets corroded and due to this after sometime,

inaccuracy occurs. The coefficient of discharge is low.

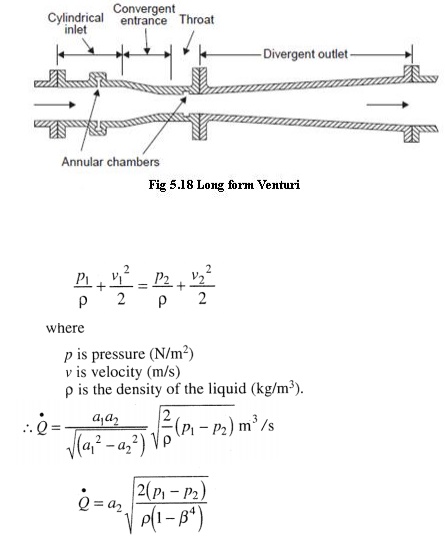

Venturi

Meter

General performance and calculations

are similar to those for orifice plates. In these devices, there is a

continuous contact between the fluid flow and the surface of the primary

device.

It consists of a cylindrical inlet

section equal to the pipe diameter, a converging conical section in which the

cross sectional area decreases causing the velocity to increase with a

corresponding increase in the velocity head and a decrease in the pressure

head; a cylindrical throat section where the velocity is constant so that the

decreased pressure head can be measured and a diverging recovery cone where the

velocity decreases and almost all of the original pressure head is recovered. The

unrecovered pressure head is commonly called as head loss.

Limitations

This flow meter

is limited to use on

clean, non- corrosive liquids and

gases, because it is impossible to clean out or flush out the pressure taps if

they clog up with dirt or debris.

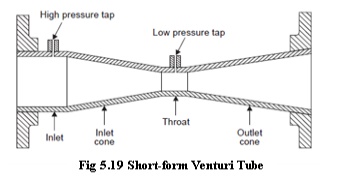

Short Form Venturi Tubes

In an effort to reduce costs and

laying length, manufactures developed a second generation, or short-form

venturi tubes shown in Figure 5.19.

There were two major differences in this design. The

internal annular chamber was replaced by a single pressure tap or in some cases

an external pressure averaging chamber, and the recovery cone angle was

increased from 7 degrees to 21 degrees. The short form venture tubes can be

manufactured from cast iron or welded from a variety of materials compatible

with the application.

The pressure taps are located one-quarter to

one-half pipe diameter upstream of the inlet cone and at the middle of the

throat section. A piezometer ring is sometimes used for differential pressure

measurement. This consists of several holes in the plane of the tap locations.

Each set of holes is connected together in an annular ring to give an average

pressure. Venturis with piezometer connections are unsuitable for use with

purge systems used for slurries and dirty fluids since the purging fluid tends

to short circuit to the nearest tap holes. Piezometer connections are normally

used only on very large tubes or where the most accurate average pressure is

desired to compensate for variations in the hydraulic profile of the flowing

fluid. Therefore, when it is necessary to meter dirty fluids and use piezometer

taps, sealed sensors which mount flush with the pipe and throat inside wall

should be used. Single pressure tap venturis can be purged in the normal manner

when used with dirty fluids. Because the venturi tube has no sudden changes in

contour, no sharp corners, and no projections, it is often used to measure

slurries and dirty fluids which tend to build up on or clog of the primary

devices.

Flow

Nozzle

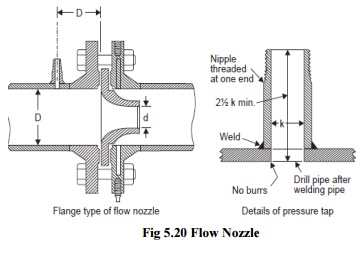

Flange Type Flow Nozzle

The Flow nozzle is a smooth, convergent section that

discharges the flow parallel to the axis of the downstream pipe. The downstream

end of a nozzle approximates a short tube and has the diameter of the

venacontracta of an orifice of equal capacity. Thus the diameter ratio for a

nozzle is smaller or its flow coefficient is larger. Pressure recovery is

better than that of an orifice. Figure shows a flow nozzle of flange type.

Advantages

1. Permanent pressure loss lower than that for an orifice plate.

2. It is suitable for fluids containing solids that settle.

3. It is widely accepted for high pressure and temperature steam

flow.

Disadvantages

1. Cost is higher than orifice plate.

2. It is limited to moderate pipe sizes, it requires more

maintenance.

Pitot

tube

An obstruction type

primary element used mainly for fluid velocity measurement is the Pitot tube.

Principle

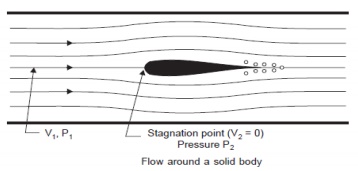

Consider Figure which shows flow

around a solid body. When a solid body is held centrally and stationary in a

pipeline with a fluid streaming down, due to the presence of the body, the

fluid while approaching the object starts losing its velocity till directly in

front of the body, where the velocity is zero. This point is known as the

stagnation point. As the kinetic head is lost by the fluid, it gains a static

head. By measuring the difference of

pressure between that at normal flow line and that at the stagnation point, the velocity is found out.

This principle is used in pitot tube sensors.

Fig 5.21 Flow through solid body

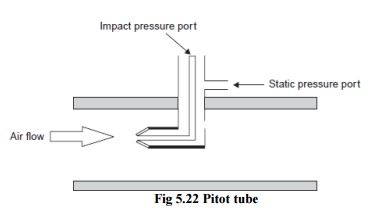

Fig 5.22 Pitot tube

A common industrial type of pitot tube

consists of a cylindrical probe inserted into the air stream, as shown in

Figure. Fluid flow velocity at the upstream face of the probe is reduced

substantially to zero. Velocity head is converted to impact pressure, which is

sensed through a small hole in the upstream face of the probe. A corresponding

small hole in the side of the probe senses static pressure. A pressure

instrument measures the differential pressure, which is proportional to the

square of the stream velocity in the vicinity of the impact pressure sensing

hole.

The velocity equation for the pitot

tube is given by,

Advantages

1. No pressure loss.

2. It is relatively simple.

3. It is readily adapted for flow measurements made in very large

pipes or ducts

Disadvantages

1. Poor accuracy.

2. Not suitable for dirty or sticky fluids and fluids containing

solid particles.

3. Sensitive to upstream disturbances.

Rotameter

The orificemeter, Venturimeter and flow

nozzle work on the principle of constant area variable pressure drop. Here the

area of obstruction is constant, and the pressure drop changes with flow rate.

On the other hand Rotameter works as a constant pressure drop variable area

meter. It can be only be used in a vertical pipeline. Its accuracy is also less

(2%) compared to other types of flow meters. But the major advantages of

rotameter are, it is simple in construction, ready to install and the flow rate

can be directly seen on a calibrated scale, without the help of any other

device, e.g. differential pressure sensor etc. Moreover, it is useful for a

wide range of variation of flow rates (10:1).

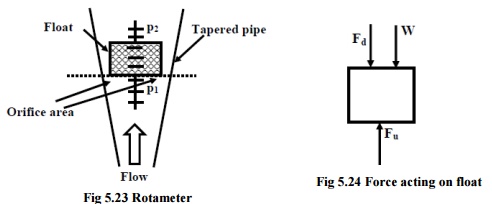

The basic construction of a rotameter is shown in

figure. It consists of a vertical pipe, tapered downward. The flow passes from

the bottom to the top. There is cylindrical type metallic float inside the

tube. The fluid flows upward through the gap between the tube and the float. As

the float moves up or down there is a change in the gap, as a result changing

the area of the orifice. In fact, the float settles down at a position, where

the pressure drop across the orifice will create an upward thrust that will

balance the downward force due to the gravity. The position of the float is

calibrated with the flow rate.

Fig

5.23 Rotameter

γ1=

Specific weight of the float

γ2=

specific weight of the fluid

ν= volume of the float

Af= Area of the float.

At= Area of the tube at equilibrium

(corresponding to the dotted line)

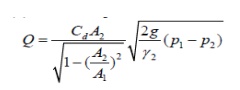

Fd = Downward thrust on the float Fu

= Upward thrust on the float

The major source of error in rotameter

is due to the variation of density of the fluid. Besides, the presence of

viscous force may also provide an additional force to the float.

Applications

·

Can be used to measure flow rates of

corrosive fluids

·

Particularly useful to measure low flow

rates

Advantages

·

Flow conditions are visible

·

Flow rate is a linear function(uniform

flow scales)

·

Can be used to measure flow rates of

liquids, gases and vapour

·

By changing the float, tapered tube or

both, the capacity of the rotameter can be changed.

Limitations

· They

should be installed vertically

· They

cannot be used for measurements in moving objects

· The

float will not be visible when coloured fluids are used, that is, when opaque

fluid are used.

· For

high pressure and temperature fluid flow measurements, they are expensive

· They cannot be used for fluids containing high percentage of solids in suspension.

Related Topics