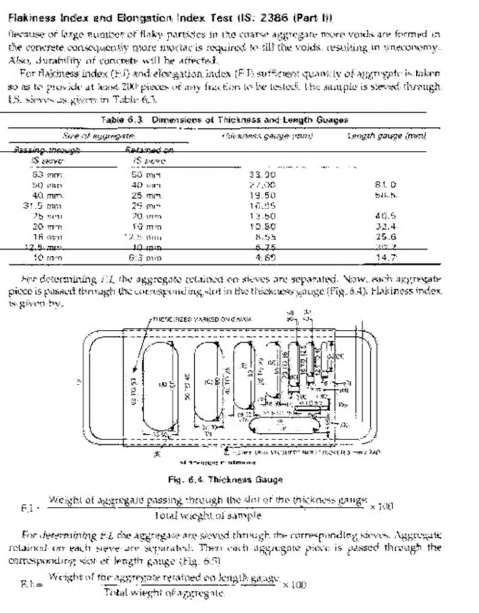

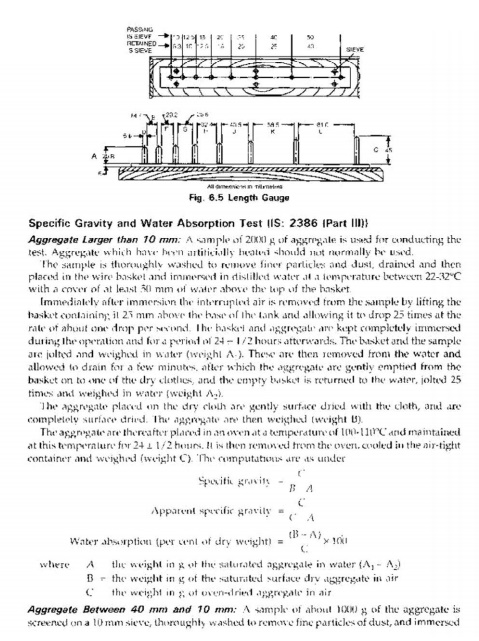

Chapter: Civil : Construction Materials: Lime, Cement, Aggregates, Mortar

Testing Of Aggregates

Testing Of Aggregates

The size,

shape, grading of aggregate and their surface moisture affect directly the

workability and strength of concrete whereas soundness, alkali-aggregate

reaction and presence of deleterious substances adversely affect the soundness

and durability of concrete. The following tests are conducted to ensure

satisfactory performance of aggregate

Table Weights of Sample

Max. size

present in substantial Proportion (mm) : Approximate sample weight (g)

63 to 25 : 6000

20 to 12.5 : 1000

10 to 6.3 : 500

4.75 or smaller : 300

For testing fine

aggregate for clay, fine silt and dust weight approximately 300g of the air

dried sample, passing the 4.75 mm IS sieve, and place it in the screw-topped

glass jar, together with 300 ml of diluted sodium oxalate solution. The jar is

then rotated about its long axis (with this axis horizontal) at a speed of 80

rpm for 15 minutes. The suspension is then poured into 1000 ml measuring

cylinder and the residue washed by gentle swirling and decantation of

successive 150 ml portions of sodium oxalate solution, the washings being added

to the cylinder until the volume is made up to 1000 ml.

For coarse

aggregate the sample is placed in a suitable container, covered with a measured

volume of sodium oxalate solution (0.8 g/l), agitated vigorously and the liquid

suspension transferred to the 1000 ml measuring cylinder. The process is

repeated until all clayey material is transferred to the cylinder. The volume

is made upto 1000 ml with sodium oxalate solution.

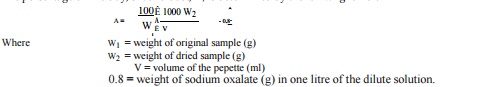

The percentage of fine

clay, silt and dust, A, is

Where W1 = weight of original sample (g)

W2 = weight of dried sample (g)

V = volume of the pepette (ml)

0.8 = weight of sodium oxalate (g) in

one litre of the dilute solution.

Note: These impurities should not exceed 3% for fine and coarse

aggregates except for crushed

fine aggregate for which the limit is 15% (IS:383).

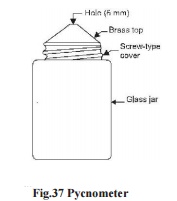

Aggregate Smaller than 10 mm: A Pycnometer

shown in Fig. 37 is used for specific gravity. A sample about 1000 g for

10 mm to 4.75 mm or 500 g if mm, is placed in the tray and covered with

distilled water at a temperature of 22-32 o C. Soon after immersion, air

entrapped in or bubbles on the surface of the aggregate are removed by gentle

agitation The sample is kept immersed for 24 ± 1/2 hours.

The water is then carefully drained from the sample through a

filter paper, retained being returned to the sample. The aggregate including

any solid on the filter paper should be exposed to a gentle current of warm air

to evaporate surface moisture and stirred at frequent intervals to insure

uniform drying until no free surface moisture can be seen and the material just

attains a free-running condition. The saturated and surface-dry sample is

weighted ( weight A).

The aggregate is then placed in the pycnometer which is filled

with distilled water. The pycnometer is dried on the outside and weighed

(weight B).

The contents of the pycnometer are emptied into the tray. The

pycnometer is refilled with distilled water to same level as before, dried on

the outside and weighed (weight C).

The water is then carefully drained from the sample by

decantation through a filter paper and any material retained is returned to the

sample. The sample is placed in the oven at a temperature of 100 to 110 o C for

24 ± 1/2 hours, during which period it shou ld be stirred occasionally to

facilitate drying. It is then cooled in the air-tight container and weighed

(weight D).

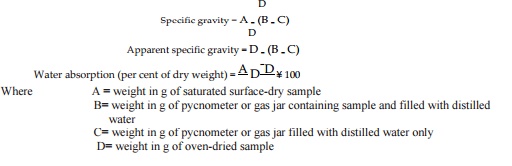

Where A = weight in

g of saturated surface-dry sample

B= weight in g of

pycnometer or gas jar containing sample and filled with distilled water

C= weight in g of

pycnometer or gas jar filled with distilled water only

D= weight in g of

oven-dried sample

Bulking Test for Fine Aggregate (IS:

2386 (Part III))

Fine aggregate

(sand) has a tendency to increase in volume (bulk) depending upon the moisture

present in it. In making concrete mix, if the batching in done by volume, the

actual quantity of sand in each batch will be less than the recommended volume

and actual quantity of sand in each batch will be less than the recommended

volume and consequently the mix will be rich in cement, i.e. the proportions of

cement and sand will be different to be provided. This will result in uneconomy

and may affect adversely teh concrete also. Therefore, the amount of sand will

have to be increased by percentage bulking (B).

The field method of

determination of bulking is explained in Sec. 6.3. In the laboratory test

sufficient quantity of oven dried sand is filled in graduated cylinder up to a

certain fixed mark. The sand is emptied in a container and the weigh of dry

sand is determined 1% water is added in the sand mixed thoroughly and filled in

the graduated cylinder. The volume of sand will be found to increase. The

process is repeated by increasing the percentage of water in steps of 1% each

time till a decrease in the volume of sand is observed. Still this addition of

water is continued till the volume of sand comes back to the original volume

(fully saturated).

A graph is plotted

between moisture content and percentage increase in volume. The graph will be

of the shape as shown in Fig. 6.2. The percentage bulking is given by,

B = bulked volume - dry volume ¥ 100 dry

volume

Crushing Value Test (IS: 2386 (Part

IV))

The material for

the test should consist of aggregate passing 12.5 mm sieve and retained on 10

mm sieve. For other sizes, the materials are separated on the appropriate

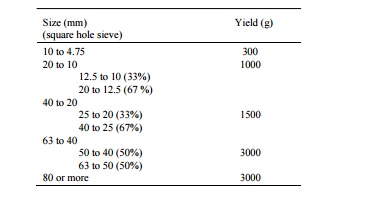

sieves given in Table 6.6.

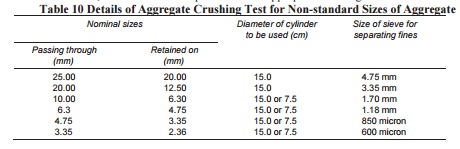

Table 10 Details of Aggregate Crushing Test for Non-standard

Sizes of Aggregate

Note: About 6500 g of natural aggregate is required to provide

samples for the 150 mm cylinder, or about 1000 g for the 75 mm cylinder.

The aggregate is

tested in a surface-dry condition. The weight of material comprising the test

sample is determined (weight A).

The cylinder of the

test apparatus is positioned on the base-plate and the test sample is added in

thirds, each being subjected to 25 strokes from the tamping rod. The surface of

the aggregate is carefully levelled and the plunger is inserted so that it

rests horizontally on this surface.

The apparatus, with

the test sample and plunger in position is then placed between the platens of

the testing machine and loaded at an uniform rate as possible, so that the

total load is reached in 10 minutes. The total load should be 400 kN.

The load is released

and the whole of the material is removed from the cylinder and sieved on a 2.36

mm sieve for the standard test, or on the appropriate sieve given in Table 6.5.

The fraction passing the sieve is weighed.

The ratio of the weight of fines formed to the total sample

weight in each test is expressed as a percentage, recorded to the first decimal

place:

Aggregate crushing value = B/A ¥ 100

Where

B = weight of fraction passing the appropriate sieve

A = weight of surface-dry sample

Aggregate Impact Value Test (IS:2386

(Part IV))

The aggregate

impact value gives a relative measure of the resistance of an aggregate to

sudden shock or impact, which in some aggregate differs from its resistance to

a slow compressive load.

The test sample consists

of aggregate the whole of which passes a 12.5 mm sieve and is retained on a 10

mm sieve. The aggregate comprising the test sample is dried in an oven for a

period of four hours at a temperature of 100-110 o C and cooled.

The measure is

filled about one-third full with the aggregate and tamped with 25 strokes of

the rounded end of the tamping rod. A further similar quantity of aggregate is

added and a further tamping of 25 strokes is given. The measure is finally

filled to overflowing, tamped 25 times and the surplus aggregate is struck off,

using the tamping rod as a straight-edge. The net weight of aggregate in the

measure is determined to the nearest gram (weight A).

A cup, 102 mm

internal diameter and 50 mm deep, is fixed firmly in position on the base of

the machine and the whole of the sample is placed in it and compacted by a

single tamping of 25 strokes of the tamping rod.

The hammer is

raised until its lower face is 380 mm above the upper surface of the aggregate

in the cup, and allowed to fall freely on to the aggregate. The test sample is

subjected to a total of 15 such blows each being delivered at an interval of

not less than one second.

The crushed

aggregate is then removed from the cup and the whole of it is sieved on 2.36 mm

IS sieve until no further significant amount passes in one minute. The fraction

passing the sieve is weighed to an accuracy of 0.1 g (weight B). The fraction

retained on the sieve is also weighed (weight C) and, if the total weight (B +

C) is less than the initial weight (A) by more than one gram, the result is

discarded and a fresh test made. Two tests are made.

The ratio of the

weight of fines formed to the total sample weight in each test are expressed as

a percentage, recorded to the first decimal place:

Aggregate impact value = AB ¥ 100

Where B = weight of fraction passing

2.36 mm sieve A = weight of oven-dried sample

Aggregate Abrasion Value Test (IS:

2386 (Part IV))

The abrasion value

of coarse aggregate may be determined by either Deval Machine or by Los Angeles

machine.

Using Deval Machine

Abrasive Charge: The abrasive charge consists of

6 cast iron or steel spheres approximately 48 mm in diameter, each weighing

between 390 and 445 g. An abrasive charge of 6 spheres weighing 2500 ± 10 g is

used with each test sample.

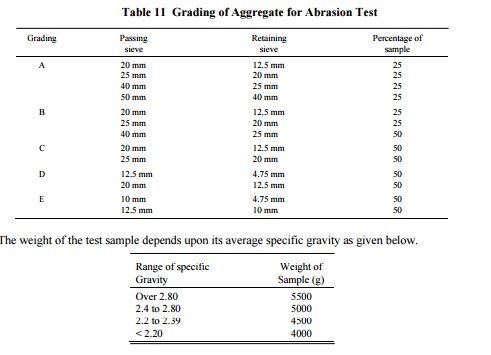

The test sample

consists of dry coarse aggregate made up of percentages of the various sizes

conforming to one of the gradings shown in Table 6.7. The grading used should

be that most nearly representing the coarse aggregate furnished for the work.

Procedure: The test sample and

the abrasive charge are placed in the Deval abrasion testing machine and the

machine is rotated for 10000 revolutions at a speed of 30 to 33 rev/min. At the

completion of the test, the material is removed from machine and sieved on a

1.70 mm sieve. The material retained on the sieve is washed, dried and

accurately weighed to the nearest gram.

The loss by abrasion is

considered as the difference between the original weight of the sample and the

weight of the material retained on the 1.70 mm sieve, expressed as percentage

of the original weight of the test sample.

In case of crushed gravel, the

percentage by weight of crushed fragments is determined, and the permissible

percentage or wear is calculated as:

W = AL (100

A)L / 100

Where W =

permissible percentage of wear

A = percentage of

uncrushed fragments

L= maximum percentage of wear

permitted by the specifications for gravel consisting entirely of uncrushed

fragments

100 - A = percentage of crushed

fragments

L = maximum

percentage of wear permitted by the specifications for gravel consisting

entirely of crushed fragments

Using Los Angeles Machine

Abrasive Charge: The abrasive

charge consists of cast iron spheres or steel spheres approximately 48 mm in

diameter and each weighing between 390 and 445 g.

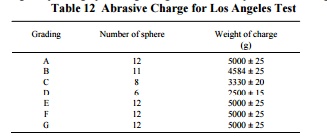

The

abrasive charge, depending upon the grading of the test sample should be as

given in Table 12.

The test sample consists of clean

aggregate dried in an oven at 105 -110 o C to substantially constant weight.

Note: It is recognized that

different specification limits may be required for gradings E, F and G than for

A, B, C and D. It is urged that investigations be conducted to determine the

relationship, if any, which exists between results for these coarse gradings

using the 10000 g samples and the finer ones using the 5000 g samples.

The test sample and the abrasive

charge is placed in the Los Angeles abrasion testing machine and the machine is

rotated at a speed of 20 to 33 rev/min. For gradings A, B, C and D, the machine

is rotated for 500 revolutions; for gradings E, F and G, it is rotated for 1000

revolutions. The machine is so driven and so counter-balanced as to maintain a

substantially uniform peripheral speed. If an angle is used as the shelf, the

machine is rotated in such a direction that the charge is caught on the outside

surface of the angle. At the completion of the test, the material is discharged

from the machine and a preliminary separation of the sample made on a sieve

coarser than the 1.70 mm. The finer portion is then sieved on a 1.70 mm

sieve.The material coarser than the 1.70 mm sieve is washed, dried in an oven

at 105 -110 o C to a substantially constant weight, and accurately weighed to the

nearest gram. The difference between the original and the final weights of the

test sample expressed as a percentage of the original weight of the test sample

gives the percentage of wear.

Soundness Test (IS: 2386 Part V)

The

sample of fine aggregate for the test is passed through 10-mm IS sieve and

should be of such size that it yields not less than 100 g of each of the sizes

as below.

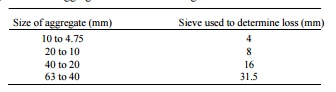

From the sample of coarse

aggregate, sizes finer than 4.75 mm are removed and the size of sample for

different sizes should be as follows.

Note: All-in-aggregate should be

separated in two major fractions, finer than 4.75 mm and coarser than 4.75 mm,

and tested.

In case of fine aggregate, these

are thoroughly washed on a 300 micron IS sieve and dried to constant weight at

105 to 110 o C and separated into different sizes by the set of sieves listed

earlier to yield at least 100g each. The coarse aggregate sample are washed

thoroughly and dried to constant weight at 105 to 110 o C and separated into

different sizes. Particles coarser than the 20 mm IS sieve are counted.

The aggregate sample is immersed

for 16 to 18 hours in the prepared solution of either sodium sulphate or

magnesium sulphate solution. The sample is maintained at 27 ± 1 o C. The

aggregate sample is then removed from the solution and drained for 15 ± 5

minutes, placed in drying oven at 105 -110 o C and dried to constant weight. The

sample is allowed to cool to room temperature. The process of immersion and

drying is repeated for as many number of cycles as agreed to between the

purchaser and vendor. The sample is then examined for quantitative and

qualitative examination.

Quantitative

examination: After the completion of final cycle the cooled sample is washed

free from the sodium sulphate or magnesium sulphate with barium chloride. Each

sample is dried to constant weight at 105 - 110 o C and weighed. Fine aggregate

are sieved over the same sieve on which it was retained before the test, and

coarse aggregate over the following sieves.

Qualitative

examination: Frations of samples coarser than 20 mm are examined qualitatively

for each immersion as well as at the completion of the test. The effects

observed may be classed as disintegration, splitting, crumbling, cracking,

flaking, etc.

Related Topics