Chapter: Civil : Construction Materials: Lime, Cement, Aggregates, Mortar

Cement: Natural Aggregates and Bulking

Natural

Aggregates: These are obtained by crushing from quarries of

igneous, sedimentary or metamorphic rocks. Gravels and sand reduced to

their present size by the natural agencies also fall in this category. The most

widely used aggregate are from igneous origin. Aggregates obtained from pits or

dredged from river, creek or sea are most often not clean enough or well graded

to suit the quality requirement. They therefore require sieving and washing

before they can be used in concrete.

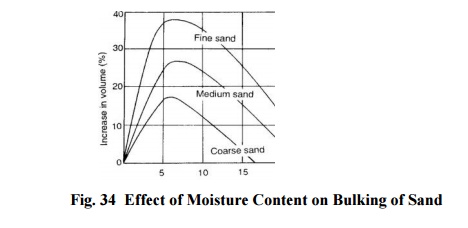

Bulking: The

increase in the volume of a given mass of fine aggregate caused by the presence

of water is known as bulking. The water forms a film over the fine

aggregate particles, exerts force of surface tension and pushes them apart

increasing the volume. The extent of bulking depends upon the percentage of

moisture present in the sand and its fineness. With ordinary sand bulking

varies from 15-30 percent. It increases with moisture content up to a certain

point (4-6%), reaches maximum, the film of water on the sand surface breaks,

and then it starts decreasing. Figure 6.2 shows the bulking of sand with

moisture content. In preparing concrete mixes if sand is measured by volume and

no allowance is made for bulking, the moist sand will occupy considerably

larger volume than that prepared by the dry sand and consequently the mix will

be richer. This will cause, less quantity of concrete per bag of cement. For

example, if the bulking of sand is 10% and if mix ratio is 1:2:4, the actual

volume of sand used will be 1.1 × 2 =2.2 instead of 2 per unit volume of

cement. If this correction is not applied the actual dry sand in the concrete

will be , instead of 2 per unit volume of cement. The mix proportion then would

be 1:1.82:4 rather than 1: 2: 4. Which indicates lesser production of concrete.

Also, there will be chances of segregation, honeycombing and reduced yield of

concrete.

Bulking

of sand can be determined, in field, by filling a container of known volume (A)

with damp sand in the manner in which the mixer hopper will be filled. The

height of sand in the container is measured. The sand is then taken out of

container carefully, ensuring no sand is lost during this transaction. The sand

is then either dried and filled back into the gauge box, or the container is

filled with water and the damp sand is poured in to displace the water.

Whichever method is adopted, the new depth of aggregate in the container gives

the unbulked volume (B).

Then

percentage bulking expressed as a percentage of the dry volume = A B

Note: The dry

and fully saturated (flooded) sand occupy almost same volume

Related Topics