Chapter: Mechanical and Electrical : Power Plant Engineering : Power Plants and Boilers

Steam Power Plants

STEAM POWER P LANTS

A thermal power station is a

power plant in which the prime mo ver is steam driven. Water is heated, turns

into ste am and spins a steam turbine which drives an electrical generator.

After it passes through the tur bine, the steam is condensed in a condenser an

d recycled to where it was heated; this is known as a Rankine cycle. The

greatest variation in t he design of thermal power stations is due to the

different fuel sources. Some prefer to use the term energy center

because such facilities convertt forms of heat energy into electricity. Some t

hermal power plants also deliver heat energy for industrial purposes, for district

heating, or for d esalination of water as well as delivering electric al power.

A large proportion of CO2 is prod uced by the worlds fossil fired thermal power

pla nts; efforts to reduce these outputs are various and widespread.

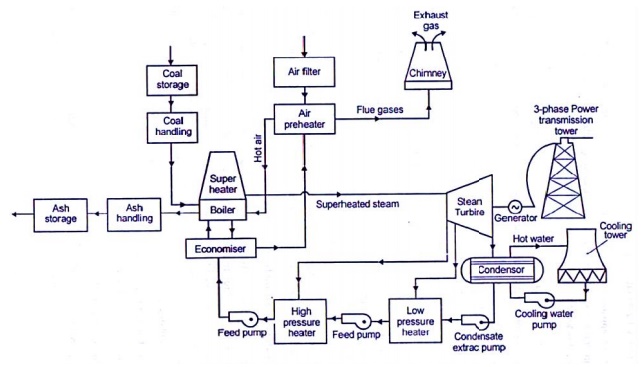

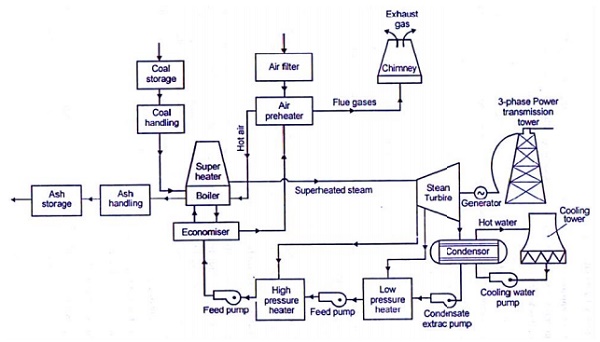

LAYOUT OF

STEAM POW ER PLANT:

The four main circuits one wo uld come across in any thermal

power plant layout are

- Coal and

Ash Circuit

- Air and

Gas Circuit

- Feed

Water and Steam Circu it

Cooling

Water Circuit

Coal and Ash Circuit

Coal and Ash circuit in a thermal

power plant layout mainly takes care of feeding the boiler with coal from the

storage for combustion. The ash that is generated during combustion is

collected at the back of the boiler and removed to the ash storage by scrap

conveyors. The combustion in the Coal and Ash circuit is controlled by

regulating the speed and the quality of coal entering the grate and the damper

openings.

Air and Gas Circuit

Air from the atmosphere is

directed into the furnace through the air preheated by the action of a forced

draught fan or induced draught fan. The dust from the air is removed before it

enters the combustion chamber of the thermal power plant layout. The exhaust

gases from the combustion heat the air, which goes through a heat exchanger and

is finally let off into the environment.

Feed Water and Steam Circuit

The steam produced in the boiler

is supplied to the turbines to generate power. The steam that is expelled by

the prime mover in the thermal power plant layout is then condensed in a

condenser for re-use in the boiler. The condensed water is forced through a

pump into the feed water heaters where it is heated using the steam from

different points in the turbine. To make up for the lost steam and water while

passing through the various components of the thermal power plant layout, feed

water is supplied through external sources. Feed water is purified in a

purifying plant to reduce the dissolve salts that could scale the boiler tubes.

Cooling Water Circuit

The quantity of cooling water

required to cool the steam in a thermal power plant layout is significantly

high and hence it is supplied from a natural water source like a lake or a

river. After passing through screens that remove particles that can plug the

condenser tubes in a thermal power plant layout, it is passed through the

condenser where the steam is condensed. The water is finally discharged back

into the water source after cooling. Cooling water circuit can also be a closed

system where the cooled water is sent through cooling towers for re-use in the

power plant. The cooling water circulation in the condenser of a thermal power

plant layout helps in maintaining a low pressure in the condenser all

throughout.

All these

circuits are integrated to form a thermal power plant layout that generates

electricity to meet our needs.

Advantages

Ø Generation

of power is continuous.

Ø Initial

cost low compared to hydel plant.

Ø Less

space required.

Ø This can

be located near the load centre so that the transmission losses are reduced.

Ø It can

respond to rapidly changing loads.

Disadvantages

Ø Long time

required for installation.

Ø Transportation

and handling of fuels major difficulty.

Ø Efficiency

of plant is less.

Ø Power

generation cost is high compared to hydel power plant.

Ø Maintenance

cost is high.

Related Topics