Chapter: Mechanical and Electrical : Power Plant Engineering : Power Plants and Boilers

Fluidised Bed Combustion (FBC)

FLUIDISED

BED COMBUSTION (FBC)

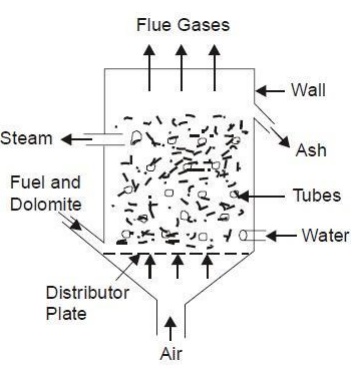

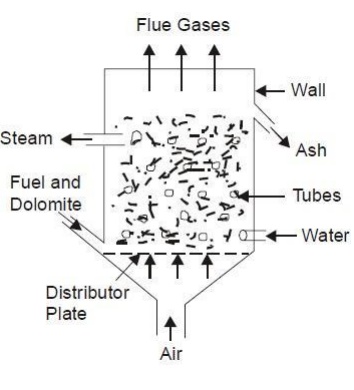

Fluidised Bed

combustion system can burn any fuel including low grade coals (even containing

70% ash), oil, gas or municipal waste. Improved desulphurisation and low NOX

emission are its main characteristics. The fuel and inert material dolomite are

fed on a distribution plate and air is supplied from the bottom of distribution

plate. The air is supplied at high velocity so that solid feed material remains

in suspension condition during burning.

The heat produced is used to heat water flowing through the tube

and convert water into

steam. During burning SO2 formed is absorbed by

the dolomite and thus prevents its escape

with the exhaust gases. The molten slag is

tapped from the top surface of the bed. The bed

temperature is nearly 800-9000C which

is ideal for sulphur retention addition of limestone or

dolomite to the bed brings down SO2 emission

level to about 15% of that in conventional firing

methods.

Various advantages of FBC system are as follows:

1. FBC system can use any type of low grade fuel including

municipal wastes and therefore is a cheaper method of power generation.

2. It is easier to control the amount of SO2 and NOX, formed during burning. Low emission of SO2 and NOX will help in controlling the undesirable effects of SO2 and NOX. During combustion. SO2 emission is nearly 15% of that in conventional firing methods.

3. There is a saving of about 10% in operating cost and 15% in the

capital cost of the power plant.

4. The size of coal used has pronounced effect on the operation and

performance of FBC system. The particle size preferred is 6 to 13 mm but even

50 mm size coal can also be used in this system.

The major

portion of the coal available in India is of low quality, high ash content and

low calorific value. The traditional grate fuel firing systems have got

limitations and are techno-economically unviable to meet the challenges of

future. Fluidized bed combustion has emerged as a viable alternative and has

significant advantages over conventional firing system and offers multiple

benefits – compact boiler design, fuel flexibility,

higher combustion efficiency and reduced emission of noxious pollutants such as

SOx and NOx.

Related Topics