Chapter: Mechanical and Electrical : Power Plant Engineering : Power Plants and Boilers

Benson Boiler (Supercritical Boiler)

BENSON BOILER (SUPERCRITICAL

BOILER)

The main difficulty experienced in the La Mont boiler is the

formation and attachment of bubbles on the inner surfaces of the heating tubes.

The attached bubbles reduce the heat flow and steam generation as it offers

higher thermal resistance compared to water film. Benson of siemens- West

Germany in 1922 argued that if the boiler pressure was raised to critical

pressure (225 atm.), the steam and water would have the same density and

therefore the danger of bubble formation can be completely removed.

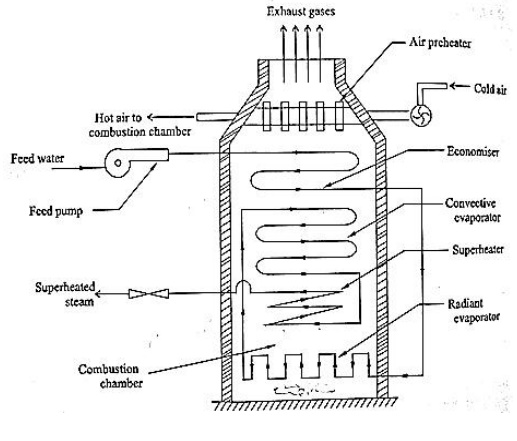

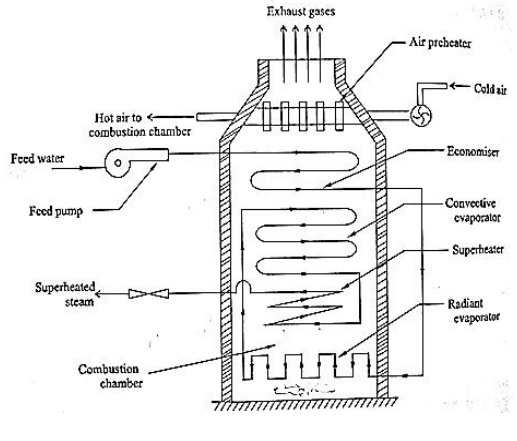

Important Components

1. Economiser – The feed water from the well passes

through the economiser where it is pre-heated by the pre-heat of exhaust

hot flue gases.

2. Radiant evaporator – The feed water after circulation

through the economiser flows through the radiant evaporator tubes. Water

is heated up by the radiation heat from the combustion chamber. Here, part of

the water is converted to steam directly.

3. Convective evaporator – The mixture of water and steam

coming out from the radiant evaporator enters the convective evaporator

tubes. The hot flue gases passing over the evaporator tubes transfer a large

portion of heat to the water by convection. Thus, water becomes steam in the

convective evaporator.

4. Superheater – The steam from the convective

evaporator enters the superheater tubes where it is superheated by the

hot flue gases passing over them. The superheated steam then enters the steam

turbine to develop power.

5. Air pre-heater – The hot flue gases then passes

through the air pre-heater where the

air required for combustion is pre-heated.

Advantages

1. As there is no drum, the total weight of Benson boiler is 20%

less than other boilers. This reduces the cost of the boiler.

2. Floor space requirements of Benson boiler are very less.

3. Transportation of Benson boiler parts and its erection is very

easy as there are no drums.

4. Natural circulation boilers require expansion joints in pipes

but the pipes in Benson boilers are welded.

Disadvantages

1. As the Benson boiler operates at high pressure and temperature,

special alloy materials are required.

2. Maintenance costs are very high.

3. This is more efficient, resulting in slightly less fuel use.

Related Topics