Chapter: Mechanical and Electrical : Power Plant Engineering : Power Plants and Boilers

Diesel Power Plants

DIESEL POWER PLANTS

Diesel power plants produce power

from a diesel engine. Diesel electric plants in the range of 2 to 50 MW

capacities are used as central stations for small electric supply networks and

used as a standby to hydroelectric or thermal plants where continuous power

supply is needed. Diesel power plant is not economical compared to other power

plants.

The diesel power plants are cheaply used in the fields

mentioned below.

1. Mobile

electric plants

2. Standby

units

3. Emergency

power plants

4. Starting

stations of existing plants

5. Central

power station etc.

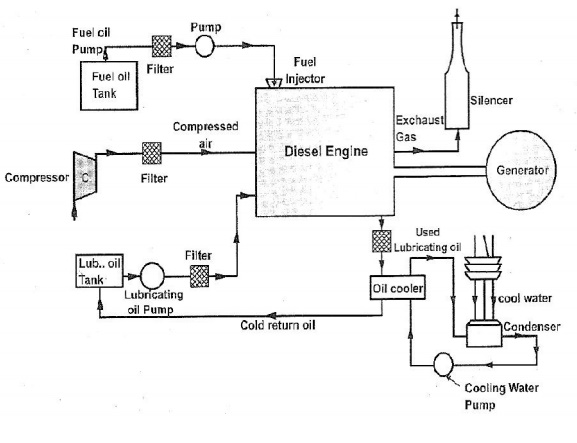

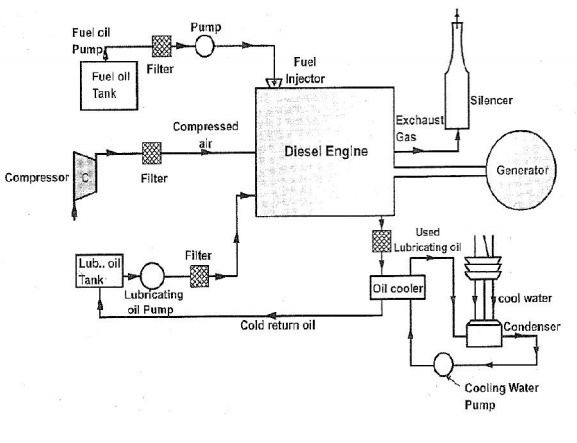

LAYOUT OF

DIESEL POWER PLANT:

Figure shows the arrangements of

the engine and its auxiliaries in a diesel power plant. The major components of

the diesel power plant are:

1) Engine

Engine is the heart of a diesel

power plant. Engine is directly connected through a gear box to the generator.

Generally two-stroke engines are used for power generation. Now a days,

advanced super & turbo charged high speed engines are available

for power production.

2) Air supply system

Air inlet is arranged outside the

engine room. Air from the atmosphere is filtered by air filter and conveyed to

the inlet manifold of engine. In large plants supercharger/turbocharger is used

for increasing the pressure of input air which increases the power output.

3) Exhaust System

This includes the silencers and

connecting ducts. The heat content of the exhaust gas is utilized in a turbine

in a turbocharger to compress the air input to the engine.

4) Fuel System

Fuel is

stored in a tank from where it flows to the fuel pump through a filter. Fuel is

injected to the engine as per the load requirement.

5) Cooling system

This system includes water circulating pumps, cooling towers,

water filter etc. Cooling water

is circulated through the engine block to keep the temperature

of the engine in the safe range.

6) Lubricating system

Lubrication system includes the air pumps, oil tanks, filters,

coolers and pipe lines. Lubricant

is given to reduce friction of moving parts and reduce the

wear and tear of the engine parts.

7) Starting System

There are three commonly used starting systems, they are;

1) A petrol

driven auxiliary engine

2) Use of

electric motors.

3) Use of

compressed air from an air compressor at a pressure of 20 Kg/cm.

8) Governing

system

The function of a governing system is to maintain the speed of

the engine constant irrespective

of load on the plant. This is done by varying fuel supply to

the engine according to load.

Advantages

Ø Diesel

power plants can be quickly installed and commissioned.

Ø Quick

starting.

Ø Requires

minimum labour.

Ø Plant is

smaller, operate at high efficiency and simple compared to steam power plant.

Ø It can be

located near to load centres.

Disadvantages

Ø Capacity

of plant is low.

Ø Fuel,

repair and maintenance cost are high.

Ø Life of

plant is low compared to steam power plant.

Ø Lubrication

costs are very high.

Ø Not

guaranteed for operation under continuous overloads.

Ø Noise is a serious problem in diesel power plant.

Ø Diesel power plant cannot be constructed for large scale.

Related Topics