Chapter: Mechanical and Electrical : Power Plant Engineering : Power Plants and Boilers

Gas Turbine Power Plants

GAS TURBINE POWER PLANTS

A gas turbine, also called a

combustion turbine, is a type of internal combustion engine. It has an upstream

rotating compressor coupled to a downstream turbine, and a combustion chamber

in-between.

Energy is

added to the gas stream in the combustor, where fuel is mixed with air and

ignited. In the high pressure environment of the combustor, combustion of the

fuel increases the temperature. The products of the combustion are forced into

the turbine section. There, the high velocity and volume of the gas flow is

directed through a nozzle over the turbine's blades, spinning the turbine which

powers the compressor and, for some turbines, drives their mechanical output.

The energy given up to the turbine comes from the reduction in the temperature

and pressure of the exhaust gas.

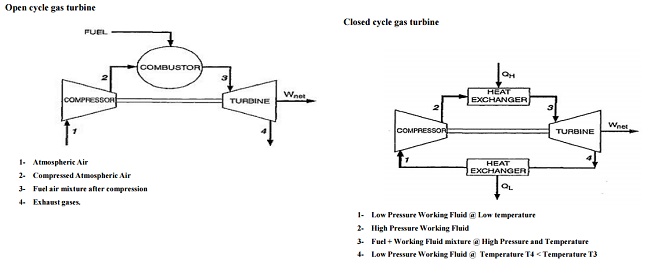

LAYOUT OF GAS TURBINE POWER PLANT

The gas turbine power plants

which are used in electric power industry are classified into two groups as per

the cycle of operation.

(1) Open cycle

gas turbine.

(2) Closed

cycle gas turbine.

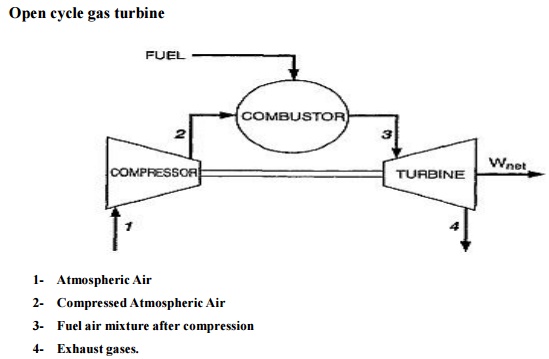

Open

cycle gas turbine

1- Atmospheric Air

2- Compressed Atmospheric Air

3- Fuel air mixture after compression

4- Exhaust gases.

The heated gases coming out of

combustion chamber are then passed to the turbine where it expands doing

mechanical work. Part of the power developed by the turbine is utilized in

driving the compressor and other accessories and remaining is used for power

generation.

Since ambient air enters into the

compressor and gases coming out of turbine are exhausted into the atmosphere,

the working medium must be replaced continuously. This type of cycle is known

as open cycle gas turbine plant and is mainly used in majority of gas turbine

power plants as it has many inherent advantages.

Advantages

1. Warm-up

time is very less.

2. Low

weight and size.

3. Almost

any hydrocarbon fuels can be used.

4. Open

cycle plants occupy comparatively little space.

6. Very

economical when compared to other plants.

7. Independent

of separate cooling medium.

Disadvantages

1. The part

load efficiency of the open cycle plant decreases rapidly as the considerable

percentage of power developed by the turbine is used to drive the compressor.

2. The

system is sensitive to the component efficiency; particularly that of

compressor.

3. The open

cycle plant is sensitive to changes in the atmospheric air temperature,

pressure and humidity.

3. The

open-cycle gas turbine plant has high air rate compared to the other cycles.

4. It is

essential that the dust should be prevented from entering into the compressor.

5. The

deposition of the carbon and ash on the turbine blades is not at all desirable

as it also reduces the efficiency of the turbine.

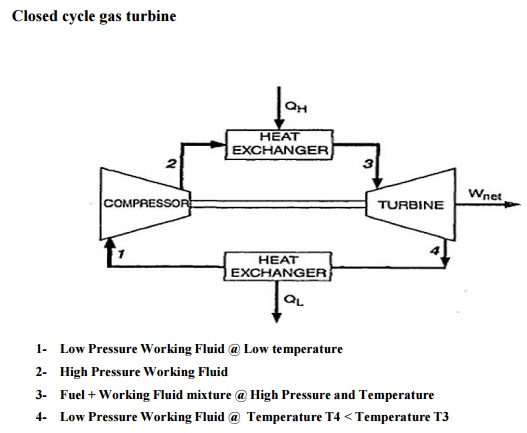

Closed

cycle gas turbine

1- Low Pressure Working Fluid @ Low temperature

2- High Pressure Working Fluid

3- Fuel + Working Fluid mixture @ High Pressure

and Temperature 4- Low Pressure Working Fluid @ Temperature T4 <

Temperature T3

In closed cycle gas turbine

plant, the working fluid (air or any other suitable gas) coming out from

compressor is heated in a heater by an external source at constant pressure.

The high

temperature and high-pressure air coming out from the external heater is passed

through the gas turbine. The fluid coming out from the turbine is cooled to its

original temperature in the cooler using external cooling source before passing

to the compressor.

The working fluid is continuously used in the system without

its change of phase and the

required heat is given to the working fluid in the heat

exchanger.

Advantages

1.The closed cycle plant is not

sensitive to changes in the atmospheric air temperature, pressure and humidity.

2. The

closed cycle avoids erosion of the turbine blades due to the contaminated gases

and fouling of compressor blades due to dust.

3. The need

for filtration of the incoming air which is a severe problem in open cycle

plant is completely eliminated.

4. Load

variation is usually obtained by varying the absolute pressure and mass flow of

the circulating medium, while the pressure ratio, the temperatures and the air

velocities remain almost constant.

5. The

density of the working medium can be maintained high by increasing internal

pressure range, therefore, the compressor and turbine are smaller for their rated

output. The high density of the working fluid further increases the heat

transfer properties in the heat exchanger.

6. As

indirect heating is used in closed cycle plant, the inferior oil or solid fuel

can be used in the furnace and these fuels can be used more economically

because these are available in abundance.

8. The

maintenance cost is low and reliability is high due to longer useful life.

Disadvantages

1. The

system is dependent on external means as considerable quantity of cooling water

is required in the pre-cooler.

2. Higher

internal pressures involve complicated design of all components and high

quality material is required which increases the cost of the plant.

3. The

response to the load variations is poor compared to the open-cycle plant.

4. It requires

very big heat-exchangers as the heating of workings fluid is done indirectly.

Related Topics