Chapter: Mechanical and Electrical : Power Plant Engineering : Power Plants and Boilers

High Pressure Boilers

HIGH PRESSURE BOILERS

A boiler is

a closed vessel in which water or other fluid is heated. The heated or

vaporized fluid exits the boiler for use in various processes or heating

applications.

In all modern power

plants, high pressure boilers (> 100 bar) are universally used as they offer

the following advantages. In order to obtain efficient operation and high

capacity, forced circulation of water through boiler tubes is found helpful.

1.

The efficiency and the capacity of

the plant can be increased as reduced quantity of steam is required for the

same power generation if high pressure steam is used.

2.

The forced circulation of water

through boiler tubes provides freedom in the arrangement of furnace and water

walls, in addition to the reduction in the heat exchange area.

3. The tendency of scale formation is reduced due to high velocity

of water.

4. The danger of overheating is reduced as all the parts are

uniformly heated.

5.

The differential expansion is

reduced due to uniform temperature and this reduces the possibility of gas and

air leakages.

Superheater

operation is similar to that of the coils on an air conditioning unit, although

for a different purpose. The steam piping is directed through the flue gas path

in the boiler furnace. The temperature in this area is typically between 1,300–1,600 degrees Celsius. While the

temperature of the steam in the superheater rises, the pressure of the steam

does not. Almost all the steam superheater systems are designed to remove

droplets entrained in the steam to prevent damage to the turbine blading and

associated piping.

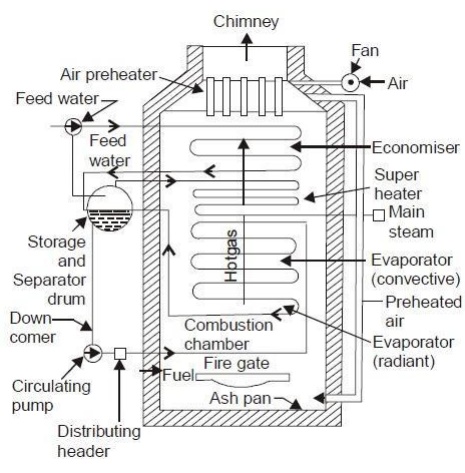

1LA-MONT BOILER

It is a forced circulation- water tube boiler which was first

introduced in 1925 by La

Mont.

The feed water from hot well is supplied to a storage and

separating drum (boiler) through the economizer. Most of the sensible heat is

supplied to the feed water passing through the economizer

The feed water from

hot well is supplied to a storage and separating drum (boiler) through the

economizer. Most of the sensible heat is supplied to the feed water passing

through the economizer. A pump circulates the water at a rate 8 to 10 times the

mass of steam evaporated. This water is circulated through the evaporator tubes

and the part of the vapour is separated in the separator drum. The large

quantity of water circulated (10 times that of evaporation) prevents the tubes

from being overheated.

The centrifugal

pump delivers the water to the headers at a pressure of 2.5 bar above the drum

pressure. The distribution headers distribute the water through the nozzle into

the evaporator. The steam separated in the boiler is further passed through the

super-heater.

To secure a uniform

flow of feed water through each of the parallel boiler circuits a choke is

fitted entrance to each circuit. These boilers have been built to generate 45

to 50 tons of superheated steam at a pressure of 120 bar and temperature of

500°C.

Important Components

1. Steam separating drum – The feed water from the hot well is

stored in the drum. The steam is separated from water in the drum and

the steam is usually collected at the top

of the drum.

2. Circulating pump – Water from the steam separating drum

is drawn by a circulating pump and it circulates water through the

evaporator tubes. Pump circulates water at a rate of 8-10 times the mass of

steam evaporated. Forced circulation is necessary to prevent the overheating of

tubes.

3. Distribution header – The distribution header distributes

the water through the nozzle into the evaporator.

4. Radiant evaporator – Water from the drum first enters the

radiant evaporator through the pump and header. The water is heated by

the radiation heat from the combustion chamber. In radiant evaporator, the hot

flue gases do not pass over the water tubes.

5. Convective evaporator – The mixture of water and steam

coming out from the radiant evaporator enters the convective evaporator

tubes. The hot flue gases passing over the evaporator tubes transfer a large

portion of heat to the water by convection. Thus, water becomes steam and the

steam enters to the steam separating drum.

6. Superheater – The steam from the steam separating

drum enters the superheater tubes where it is superheated by the hot

flue gases passing over them. The superheated steam then enters the steam

turbine to develop power.

7. Economiser – The waste hot flue gases pass

through the economiser where feed water is pre-heated. By pre-heating

the feed water, the amount of fuel required to convert water into steam is

reduced.

8. Air pre-heater – The hot flue gases then passes

through the air pre-heater where the air required for combustion is

pre-heated.

Advantages

1. La-Mont boilers can generate 45 to 50 tons of superheated steam

at a pressure of 120 bar and temperature of 500°C.

2. Drum is of small size.

3. Tendency of scale formation is eliminated due to forced

circulation of water.

Disadvantages

1. Bubbles are formed on the inside of the water tubes and this

bubbles reduce the heat transfer rate.

2. Initial and operating costs are high.

3. Maintenance costs are very high.

Related Topics