Chapter: Mechanical and Electrical : Power Plant Engineering : Power Plants and Boilers

Magneto Hydr O Dynamic (Mhd) Power Plants

MAGNETO HYDRO DYNAMIC (MHD) POWER PLANTS

MHD power generatio n is a new

system of electric power generation which is said to be of high efficiency and

low pollution. In advanced countries MHD generator are widely used but in

developing countries li ke India it is still under construction. This con

struction work is in progress at Tiruchirapalli in Tamilnadu under joint

efforts of BARC (Bhab ha Atomic Research Centre), BHEL, Associated Cement

Corporation and Russian technologist s.

As its name implies,

magneto-hydro-dynamic (MHD) is concern ed with the flow of conducting fluid in

presence of magnetic and electric field. This fluid may be gas at elevated

temperature or liquid metal li ke sodium or potassium.

A MHD generator is a device for

converting heat energy of fuel directly into electric energy without a

conventiona l electric generator. The basic difference be tween conventional

generator and MHD generator is in the nature of conductor.

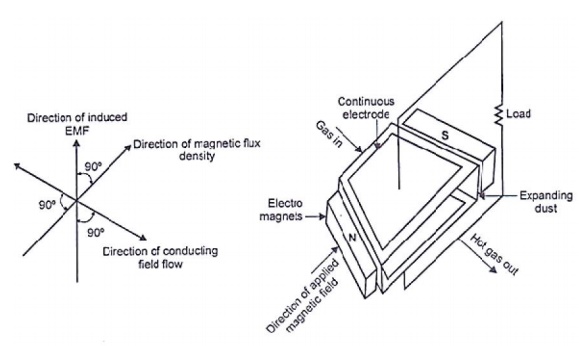

Principle

of MHD Power Ge neration

When an electric con ductor moves

across a magnetic field; an e mf is induced in it, which produced an electric

current. This is the principle of the conventi onal generator also, where the

conductors consists of copper strips.

In MHD

generator the solid conductors are replaced by a gaseo us conductor; i.e.an

ionized gas. If such gas is passed at high velocity through a powerful mag

netic field, a current is generated and can extract b y placing electrodes in a

suitable position in t he stream.

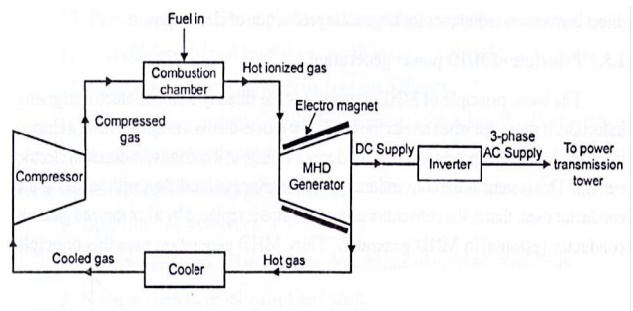

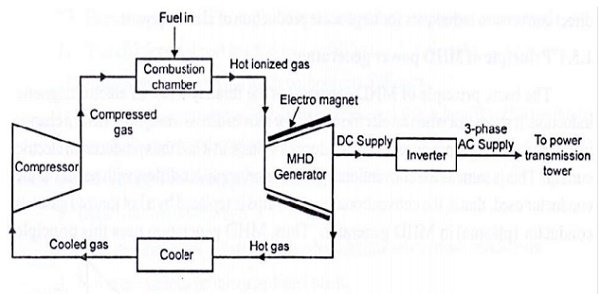

LAYOUT OF MHD POWER PLANT

A MHD conversion is known as

direct energy conversion because it produces electricity directly from heat

source without the necessity of the additi onal stage of steam generation as in

a steam po wer plant. An ionized gas is employed as a conducting field.

Ionization is produced either by thermal means i.e. by an elevated temperature or

by seeding with substance like cesium or potassium vapour which ionize at

relatively low temperature.

The atom of seed element split

off electrons. The presence of negatively charge electrons make the carrier gas

an electrical conductor.

Advantages

1. Large

amount of power is g enerated.

2. No moving

parts, so more reliable.

3. Closed

cycle system produ ces power, free of pollution.

4. Ability

to reach its full pow er as soon as started.

5. Size of

the plant is consider ably small.

6. Low

overall operation cost.

7. Better

utilization of fuel.

Disadvantages

1. Needs

very large magnets (high expensive).

2. Very high

friction and heat transfer losses.

3. It

suffers from the reverse flow of electrons through the conducting fluid s

around the ends

of the

magnetic field.

Related Topics