Chapter: Mechanical : Robotics : Sensors and Machine Vision

Slip sensing

Slip

sensing

Humans can grasp an object without information such

as a coefficient of friction or weight. To implement this graspingmotion with

the robot hand, sensors have been proposed that detect an incipient slip within

the contact surface or stick-slip.

Method of slip detection

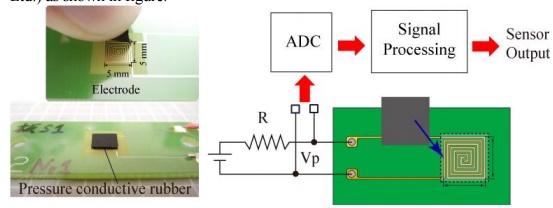

The sensor is constructed of electrode and pressure

conductive rubber(Inaba Rubber Co., Ltd.) as shown in figure.

The voltage difference Vp is measured and the signal

processing is performed. Then the initial slip can be detected. The pressure

conductive rubber was a high polymer material primarily composed of silicone

rubber with carbon particles uniformly distributed within.

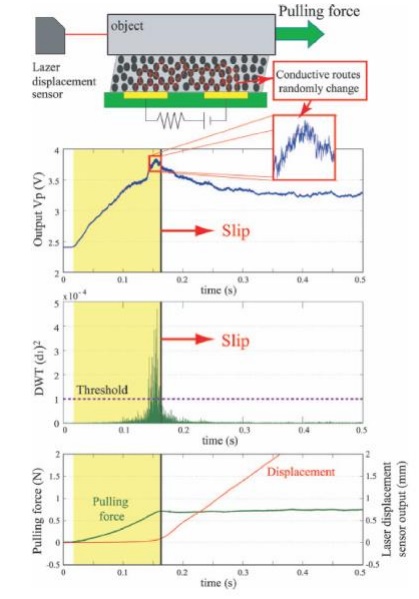

As shown in figure, the

object is placed on the surface of the sensor. The upper graph shows

the output of the

slip sensor when

pulling force is

applied to the

object.

The lowest

graph shows the pulling

force and its position

shifts through slippinge.

First, the pulling force

is increased until about 0.15s, after which it remains roughly constant.

Specifically, it can be considered that a transition from static friction to

dynamic friction occurs at the place marked with a verticalline in the figure.

In an unloaded condition, the electrical resistance

is infinity. However, the electrical resistance changes when the normal force

was added, because the mutual contact between carbon particles increases.

Moreover, when added a tangential force, the electrical resistance randomly

changes by changing the mutual contact between carbon particles.

Here, looking at the enlarged portion of the upper

graph, a complex change in the voltage emerges immediately before the

occurrence of slip (the time of the initial slip). Upon performing a frequency

analysis with respect to this voltage change, it was found that the sensor

output Vp at the time of the initial slip includes a high frequency component

of severalkHztoseveral10kHz.In this regard, such high-frequency change does not

occur when thechangeinforceisinnormaldirection.The slip sensor presented here

extracts this high-frequency component by applying the discrete wavelet

transform (DWT) and detects the initialslipoftheobject.The middle graph

presents the results of DWT power using Haar wavelets. It is clear that

immediately before slip occurs, the DWT power increases.

Frame Grabbers

Hundreds of frame grabbers are on the market to

allow integration of digital and analog machine-vision cameras with host

computers. Varying features make each one unique for a particular application.

When evaluating frame grabbers for a specific application, developers must be

aware of specific camera types (either digital or analog), the sensor types they

use (area or linescan), their systems requirements, and the cost of

peripherals.

Digital Frame Grabbers

To guarantee low latency between image acquisition

and processing, frame grabbers with digital camera interfaces such as Camera

Link cameras are often used, especially

in

high-speed semiconductor applications. The Cam a maximum of 680 Mbytes/s

(64-bit at 85 MHz), currently the highest bandwidth on the market.

High-speed

applications can also benefit from onboard tap reordering that can be

accomplished with many frame grabbers. This removes the burden of recomposing

an entire image from complex multitap cameras (several simultaneous data

channels) from the host computer. Other features, such as the recently

available power-over-Camera Link standard, offer simpler integration (a single

cable for power and data) of compatible Camera Link cameras when this feature

is available on the frame grabber.

Related Topics