Chapter: Pharmaceutical Drug Analysis: Gas Liquid Chromatography (GLC)

Instrumentation - High Performance Liquid Chromatography (HPLC)

INSTRUMENTATION

Modern HPLC essentially comprises of the following main

components namely :

(i) Solvent

reservoir and degassing system,

(ii) Pressure,

flow and temperature,

(iii) Pumps and

sample injection system,

(iv) Columns,

(v) Detectors,

(vi) Strip-chart

recorder, and

(vii) Data

handling device and microprocessor control.

All these vital components will be discussed with

adequate details, wherever necessary, in the various sections that follow :

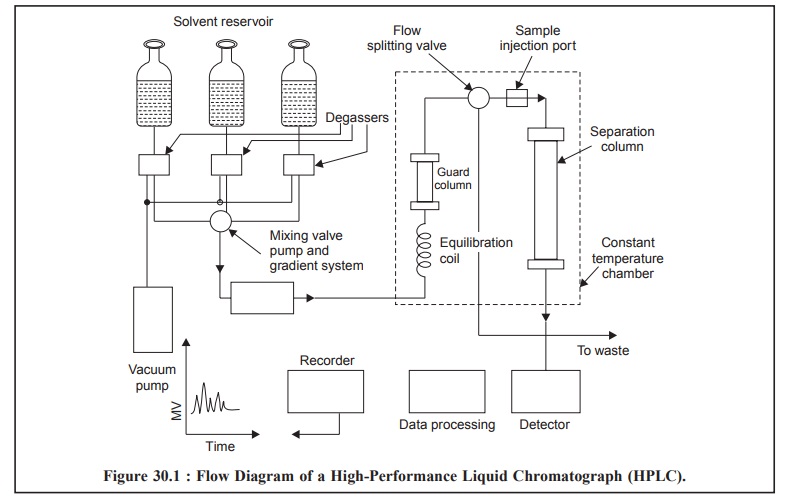

The Figure 30.1, illustrates the flow diagram of a high

performance liquid chromatograph, wherein all the vital components have been

duly represented.

The mobile phase, that may be either a single liquid or a

mixture of two or more liquids, is pumped at high pressure into a temperature

controlled oven, where it first, gains its entry into an equilibration coil to

bring it to the operating temperature, and secondly, through a ‘guarded column’

specially designed and strategically positioned to protect the analytical

column from impurities and ultimately extend its lifetime.

1. SOLVENT RESERVOIR AND DEGASSING SYSTEM

Mobile phase consisting of mixture of organic solvents or

an aqueous-orgainc mixture or a buffer solution may be employed depending upon

the chromatograohic method vis-a-vis the detector to be used.

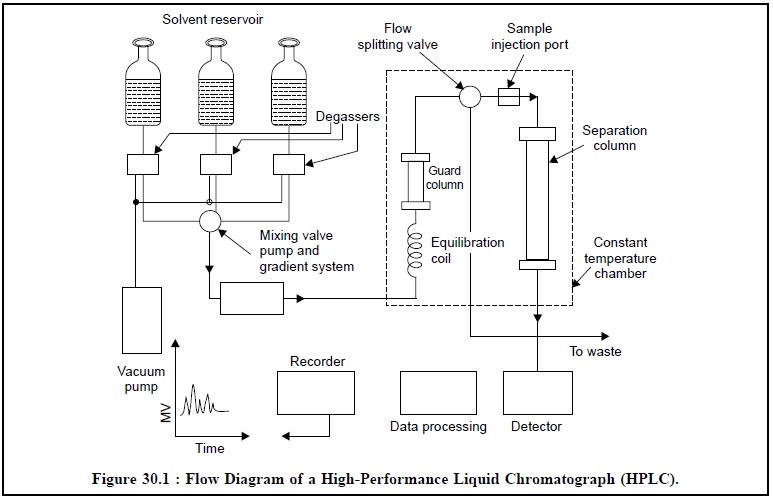

2. PRESSURE, FLOW AND TEMPERATURE

There are, in fact, several factors that are solely

responsible for the ‘pressure’

developed in a column, namely :

(a) the length

of the column,

(b) particle

size of the stationary phase,

(c) viscosity

of the mobile-phase, and

(d) flow-rate

of the mobile-phase.

The pressures mentioned above correspond to mobile-phase

flow rates of approximately 1-5 cm3 min–1 through the column.

Flow : The flow can be measured

periodically at the column outlet by collecting the liquid for a known period, and thereafter, either

measuring the volume or weighing it physically.

Temperature : In reality, the maintenance of

strict ‘temperature control’ plays a vital role in measuring the retention-data correctly and

precisely. It makes use of the refractometer detectors specifically. In HPLC,

difficult separations may be achieved by increasing the temperature carefully,

but this must be done initially on a hit and trial basis.

3 PUMPS AND SAMPLE INJECTION SYSTEM

Pumps : The two major functions of the pump in a modern HPLC are, namely :

(i) To pass the

mobile-phase through the column at a high pressure, and

(ii) At a

constant a controlled flow rate.

HPLC makes use of two types of pumps. They are :

(a) Constant Pressure Pump : A

constant-pressure pump acts by applying a constant pressure to the

mobile-phase. The flow rate through the column is determined by the flow

resistance of the column.

(b) Constant Flow Pump : A constant-flow

pump affords and maintains a given flow of liquid. The pressure developed

entirely depends upon the flow resistance.

Importantly, in a constant-pressure pump the flow rate

will change if the flow resistance changes. Whereas in the constant flow pumps

the changes in flow resistance are compensated duly by a change of pressure.

Therefore, it is always advisable to use constant flow pump in HPLC

determinations.

Salient features of HPLC pump are as follows :

(i) Interior of

the pump must not be corroded by any solvent to be used in the system,

(ii)

Variable-flow-rate device must be available to monitor flow rate,

(iii) Solvent

flow must be non-pulsing,

(iv) Changing

from one mobile-phase to another must be convenient, and

(v) It should

be easy to dismantle and repair.

The pump is a very delicate and sensitive part of HPLC

unit ; therefore, all buffer solutions should be removed carefully after use

either by pumping water (HPLC-grade) or an appropriate solvent (HPLC-grade) for

several minutes.

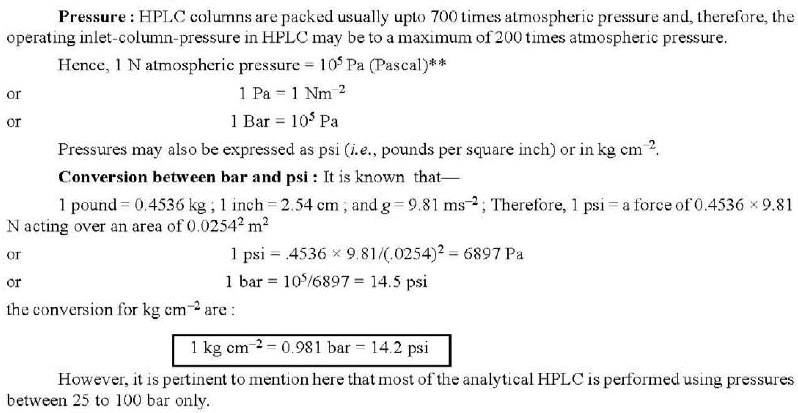

Reciprocating Pump : Figure 30.2 represents the

schematic diagram of a typical reciprocating pump along with its various essential components. The piston is moved

in and out of a solvent chamber by an eccen-tric cam or gear. The

forward-stroke closes the inlet-check value while the outlet valve opens and

the respective mobile phase is duly pumped into the column. Consequently, the

return-stroke-closes the outlet valve and it refills the chamber.

Advantages : It has the following

advantages, namely :

(i) It has an

unlimited capacity,

(ii) The

internal-volume can be made very small from 10-100 μ l,

(iii) The

flow-rate can be monitored either by changing the length of the piston or by

varying the speed of the motor, and

(iv) It has an easy access to

the valves and seals.

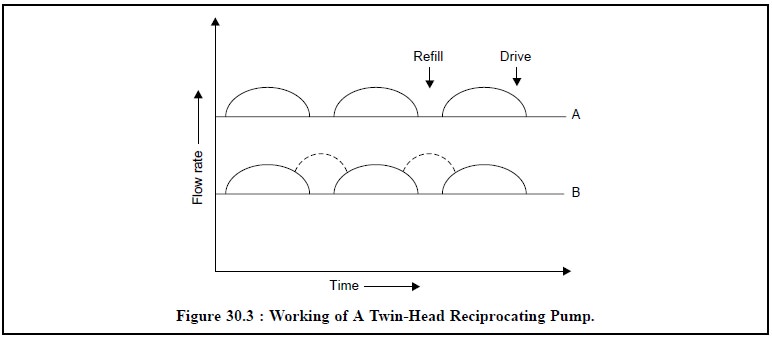

The use of twin-head reciprocating pump (i.e., having the two heads operated 180°

out of phase) func-tions in such a manner that while one head is pumping, the

other is refilling as could be seen in Figure 30.3.

In Figure 30.3, the flow rate of a twin-head reciprocal

pump has been plotted against time. The stage-A depicts the drive while the

refill zone is vacant ; while the stage-B evidently shows the two-heads

functioning simultaneously thereby the drive and the refill both zones could be

visualized.

Sample Injection System : There are in all three different modes of sample injection

system that are used in HPLC, namely

:

(a) Septum Injectors : They usually permit

the introduction of the sample by a high pressure syringe through a

self-sealing elastometer septum. The major drawback associated with this type

of injec-tors is ‘leaching effect’

of the mobile-phase just in contact with the septum, thereby resulting in the

formation of ‘ghost peaks’ or ‘pseudo peaks’. In short, in HPLC the

mode of syringe injection brings about more problems than in GC.

(b) Stop-flow Septumless Injection : Here,

most of the problems associated with septum-injectors have been duly

eliminated. The flow of the mobile-phase through the column is stopped for a

while, and when the column reaches an ambient pressure the top of the column is

opened and the sample introduced at the top of the packing.

The first two methods are relatively very cheap.

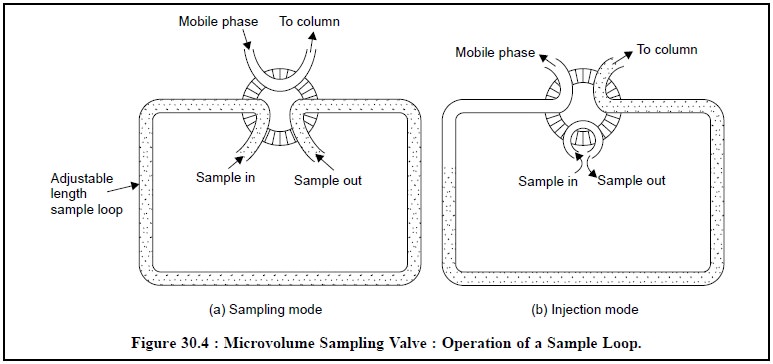

(c) Microvolume Sampling Valves : Highly

sophisticated modern HPLC frequently make use of microvolume sampling valves

for injection which not only give fairly good precision, but also are adaptable

for automatic injection. These valves enable samples to be introduced

reproducibly into pressurized columns without causing the least interruption of

the mobile-phase flow.

Figure 30.4, displays the operation of a sample loop in

two different modes i.e., (a) sampling mode and (b) injection mode. Here, the sample is

loaded at atmospheric pressure into an external loop in the

microvolume-sampling valve, and subsequently injected into the mobile-phase by

a suitable rotation to the valve. However, the volume of sample introduced

usually ranges between 2 µl to over 100 µl ; but can be varied either by

altering the volume of the sample loop or by employing specific variable-volume

sample valves.

Therefore, it is always preferred for most quantitative

work by virtue of its very high degree of precision and accuracy.

4. COLUMNS

(a) Dimensions and Fillings : Following are

the various dimensions of HPLC columns :

Material:

Stainless-steel (highly polished surface)

External Diameter: 6.35

mm (or ≡ 0.25 inch),

Internal Diameter: 4-5

mm (usual : 4.6 mm), and

Length: 10-3 cm (usual :

25 cm).

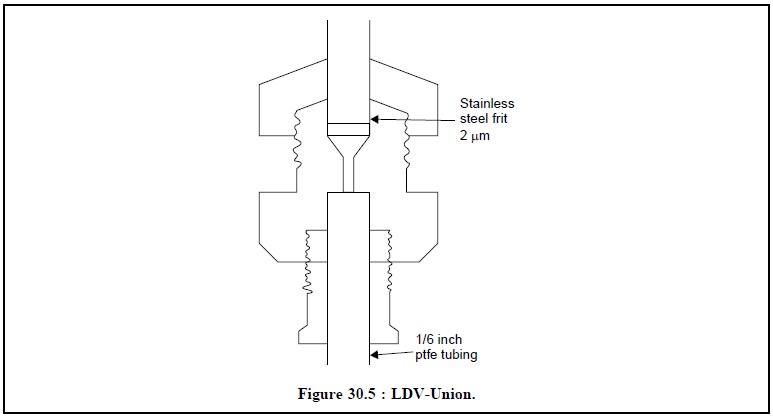

(b) Fittings : Each end of the column is

adequately fitted with a stainless-steel gauze or frit with a mesh of 2 μ m or less so as to retain the packing material (usually

having a particle diameter 10, 5 and 3 μ m).

A stainless-steel-reducing union for a column of ID 4.6

mm type makes use of a 1/4-1/6 inch union with a short length of 0.25 mm (or

0.01 inch) ID ptfe tube so as to connect the column to the detector.

In actual practice, three conventional reducing unions

available are employed, namely :

(i) Large Dead Volume (LDV)) Union :

Loss of efficiency,

(ii) Zero Dead Volume (ZDV) Union :

Loss of efficiency, and

(iii) Low Dead Volume (LDV) Union :

Most efficient, most expensive, and dead-volume 0.1 μ l.

Figure 30.5 depicts the diagram of a typical LDV-Union

having a SS-frit of 2 μ m and a ptfe tubing of 1/6

inch.

(i)

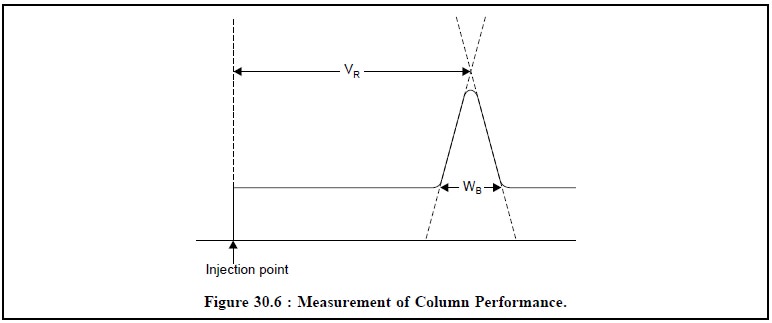

Performance : Inside a column the

concentration of a band of solute decreases as it moves through the system. The

column performance or the efficiency of a column entirely depends on the amount

of spreading that takes place. The measurement is represented in Figure 30.6,

below :

The efficiency or

performance of a column may be measured by the following expression :

N = 16(VR/WB)2 ...(a)

H = L/N ...(b)

VR = Retention volume of a solute,

WR = Volume occupied by a solute (or ‘Peak-Width’). Evidently, for a more

efficient column, WB will be smaller at a given value of VR,

H= Plate number of the column

(dimensionless), H = Plate height of the column (mm × μ m), and L = Length of the column (cm).

Based on Eq. (b)

one may clearly observe that for a more efficient column ‘N’ gets larger and

corre-spondingly ‘H’ gets smaller.

(iii) Types of Packing : Modern HPLC makes

use of packing which essentially consist of small and rigid particles with a

very narrow particle size distribution. Broadly speaking three types of packing

are invariably used in HPLC column, namely :

(a) Styrene-divinylbenzene copolymers based

porous polymeric beads have been employed exclusively for size-exclusion and

ion-exchange chromatography, but now mostly been replaced by silica-based

packings that proved to be more efficient and mechanically stable.

(b) Porous-layer beads with a diameter

ranging between 30-35 μ m comprising of a thin shell

(1-3 μ m) of silicon or modified

silica, on an inert spherical core material, such as : glass beads are still

being employed for certain ion-exchange procedures ; but of late their usage as

such in HPLC have been superseded by 100% porous microparticulate packings, and

(c) Porous-silica particles (100%) with a

diameter less than 1 μ m and narrow-particle size

range, nowadays, form the basis of most abundantly available important column

packings used in analytical HPLC. In comparison to the porous-layer beads, as

detailed in (b) above, the

porous-silica particles yield significant improvements not only in column

efficiency but also in sample capacity and speed of analysis.

5. DETECTORS

The main function of the detector in HPLC is to monitor

the mobile-phase coming out of the column, which in turn emits electrical

signals that are directly proportional to the characteristics either of the

solute or the mobile-phase.

The various detectors often used in HPLC may be

categorized into three major heads,

namely :

(i) Bulk-property detectors : They

specifically measure the difference in some physical property of the solute

present in the mobile-phase in comparison to the individual mobile-phase, for

instance :

(a)

Refractive-index detectors, and

(b)

Conductivity detectors.

(ii) Solute-property detectors. They

critically respond to a particular physical or chemical characteristic of the

solute (in question), which should be ideally and absolutely independent of the

mobile-phase being used. But complete independence of the mobile-phase is

hardly to be seen, however, signal discrimination is good enough to enable

distinctly measurable experimental procedures with solvent changes, such as :

gradient-elution.

The solute-property detectors include :

(a)

UV-detectors, and

(a)

Fluorescence Detectors.

(iii) Multipurpose detectors : Besides,

providing a high degree of sensitivity* together with a

broad-linear-response-attainable range, invariably a particular situation

critically demands detectors of more selective nature in the domain of

‘analytical chemistry’ vis-a-vis

‘Pharmaceutical Analysis’ that could be accomplished by using ‘multipurpose

detectors’, such as : “Perkin-Elmer ‘3D’

Sys-tem” that combines UV absorption, fluorescence and conductometric

detection.

(iv) Electrochemical detectors :

‘Electrochemical detector’ in HPLC usually refers to either amperometric or

coulometric detectors, that specifically measure the current associated with

the reduction or oxidation of solutes. As only a narrow spectrum of compounds

undergo electrochemical oxidation, such detectors are quite selective ; and

this selectivity may be further enhanced by moni-toring the potential applied

to the detector so as to differentiate between various electroactive spe-cies.

Naturally, electrochemical detection essentially makes use of conducting mobile

phases, for instance : inorganic salts or mixtures of water with water-miscible

organic solvents.

The five important

types of detectors shall be discussed along with their simple diagrammatic

sketches, in the sections that follow :

5.1. UV-Detectors

Principle : An UV-detector is based on the

principle of absorption of UV visible light from the effluent emerging out of the column and passed

though a photocell placed in the radiation beam.

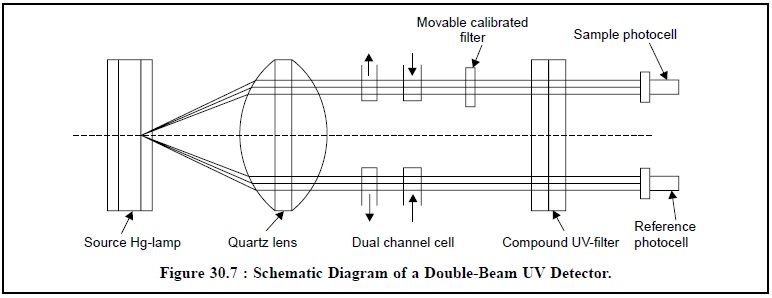

Figure 30.7 represents the schematic diagram of a

double-beam UV detector used in HPLC system. Initially, dual-wavelength

instruments having 254 and/or 280 nm were introduced which is presently being

replaced by more sophisticated and up-dated variable wavelength detectors

spread over wide range between 210-800 nm capable of performing more selective

detection possible.

Diode Array Detector (or Multichannel Detector) is also a UV detector wherein a

polychromatic light is made to pass

through the flow cell. A strategically placed grating diffracts the outcoming

radiation and subsequently meets an array of photodiodes whereby each

photodiode receives a different narrow wavelength band. Here, a microprocessor

scans the array of diodes several times in one second and the resulting

spectrum is visualized on the screen of a VDU or subsequently stored in the

instrument for a printout as and when required. Another extremely important and

useful characteristic feature of a diode-array detector is that it may be

‘programmed’ so as to affect changes in the detection wavelength at particular

points in the chromatogram. This versatile criterion is used to ‘clean up’ a chromatogram i.e., to discard all interfering peaks

caused due to components irrelevantly present in the sample.

Advantages : Various advantages are, namely

:

(a) A very

selective detector which will detect only such solutes that specifically absorb

UV/visible radiation e.g., alkenes,

aromatics and compounds having multiple bonds between C, O, N and S.

(b) The

mobile-phase* employed ideally must not absorb any radiation.

5.2. Fluorescence Detector

A plethora of compounds (solutes) present in the

mobile-phase on being passed as column effluent through a cell irradiated with

Xenon or Deuterium source first absorb UV radiation and subsequently

emit-radiation of a longer wavelength in two different manners, namely :

(a)

Instantly-termed as ‘Fluorescence’,

and

(b) After a time-gap-known

as ‘Phosphorescence’.

Fluorescent compounds : A relatively small proportion

of inorganic and organic compounds exhibit

natural fluorescence, whereas a larger number of pharmaceutical substances

and environmental contaminants [e.g.,

polycyclic aromatic hydrocarbons (PAH)] having a conjugated-cyclic system are

fluorescent. Such com-pounds having absorbed energy being re-emitted from

0.1-1.0 can be detected by a fluorescence detector. However, non-fluorescent

compounds can be converted to fluorescent derivatives by treatment with

appropri-ate solvents.

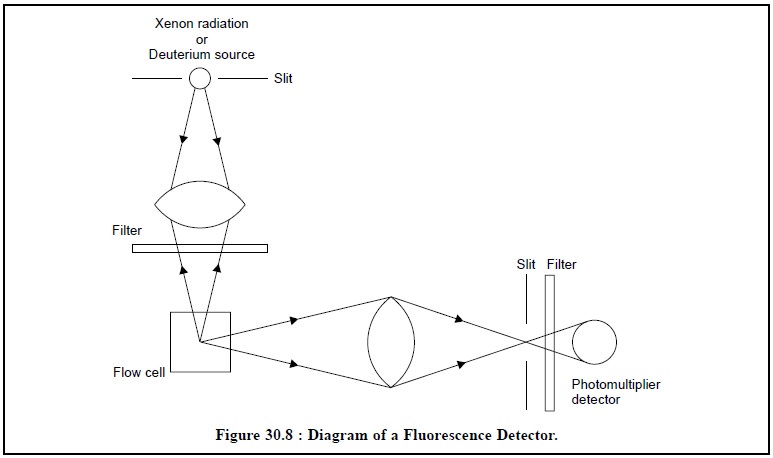

Figure 30.8, illustrates the diagram of a fluorescence

detector :

Radiation from a Xenon-radiation or a Deuterium-source is

focussed on the flow cell through a filter. The fluorescent radiation emitted

by the sample is usually measured at 90° to the incident beam. The second

filter picks up a suitable wavelength and avoids all scattered light to reach

ultimately the photomultiplier detector.

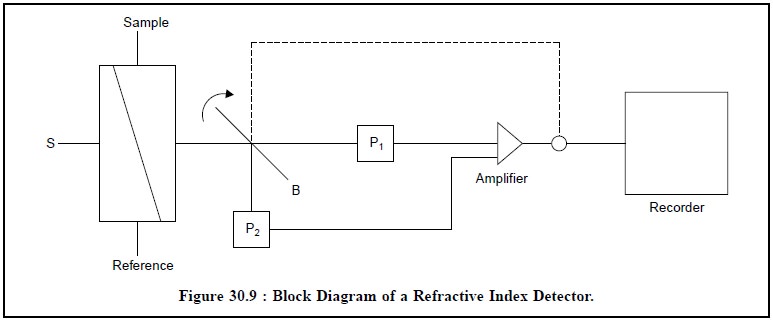

5.3. Refractive Index Detector

It is also known as ‘RI-Detector’

and ‘Refractmeter’. Figure 30.9,

represents the block-diagram of a refractive-index detector.

Light from the source(s) is focused into the cell, that

consists of sample and reference sample ; and the two chambers are separated by

a diagonal sheet of glass. After passing through the cell, the light is

diverted by a beam-splitter (B) to two photocells (P1 and P2

respectively. A change in the observed refractive index (RI) of the sample

stream causes a difference in their relative output, which is adequately

amplified and recorded duly.

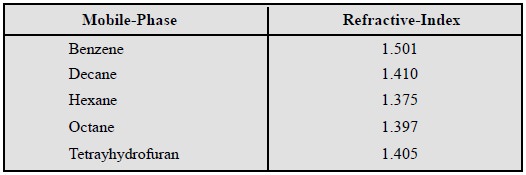

The RI of a few commonly used mobile-phase is stated

below :

Any solute can be detected as long as there exists a

measurable difference in refractive index between the solute and the

mobile-phase.

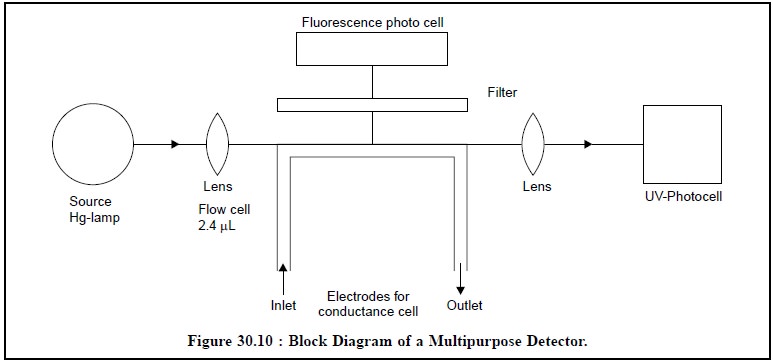

5.4. Multipurpose Detector

A multipurpose detector essentially comprises of three

detectors combined and housed together in a single unit. A typical example of

such a detector is the one developed by Perkin-Elmer known as “Perkin-Elmer ‘3D’ System” which is

depicted in Figure 30.10.

The functions of the three different detectors used in

Figure 30.10 are enumerated as under :

(i) Fluorescence Function : It can monitor

emission above 280 nm, based on excitation at 254 nm,

(ii) UV-Function : It is fixed wavelength

254 nm detector, and

(ii)

Conductance-Function : The metal inlet and outlet

tubes serve as electrodes to measure the con-ductance of the ions.

5.5. Electrochemical Detectors

In actual practice, however, it is rather difficult to

utilize the functions of electrochemical reduction as a means of detection of

HPLC by virtue of the fact that the serious interference (i.e., large background current) generated by reduction of oxygen in

the mobile phase. As complete removal of oxygen is almost difficult, therefore,

electrochemical detection is normally based upon the oxidation of the solute.

Examples : The various compounds that may

be detected conveniently are, namely : aromatic amines, phenols, ketones, and

aldehydes and heterocyclic nitrogen compounds.

In short, the amperometric

detector is presently considered to be the best electrochemical detector

having the following distinct advantages, such as :

(i) very small

internal cell-volume,

(ii) high

degree of sensitivity,

(iii) more

limited range of applications, and

(iv) excellent

for trace analyses as UV-detector lacks adequate sensitivity.

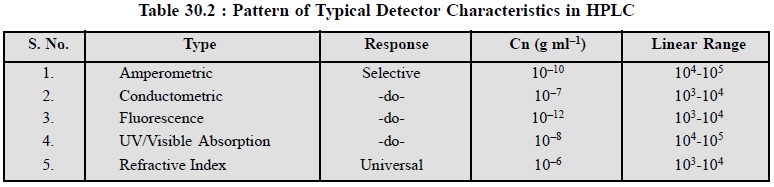

Table 30.2, provides a comprehensive comparison of

various typical detector characteristics invariably used in HPLC, such as :

response, concentration expressed in g ml–1 and the linear range.

However, the linear range usually refers to the range over which the response

is essentially linear. It is mostly expressed as the factor by which the lowest

factor (i.e., Cn) should be

multiplied in order to obtain the highest concentration.

6. STRIP CHART RECORDER

The signal emerging from the detector of a HPLC is

recorded continuously as function of time most commonly with the help of a

potentiometric recorder. Invariably, a recorder of 1 to 10 mV full-scale deflec

tion over a stretch of approximately ten inches and having a response-time of

one second or even less is regarded as most appropriate. Strip-chart recorder

with variable chart speeds ranging between 5 to 5 mm min–1 are

usually preferred.

The input signal of a potentiometric-recorder is balanced

continuously with the help of a feedback signal arrangement (device) using a servomechanism. A pen attached to this

device moves proportionately, with preadjusted attenuation, along the width of

the chart-paper thereby recording the signal accurately, while the chart-paper

moves at a fixed speed along the length.

It is pertinent to mention here that before commencing

the operation of a recorder, its zero point must be adjusted with the input

zero, otherwise the baseline will also shift with slight changes in the

attenuation of the signal.

Besides, it is also equally important to adjust properly

the amplifier gain so as to eliminate completely the dead-band and the

oscillations. A recorder having inadequate shielding from the AC circuits may

display shifting of its zero point.

7. DATA HANDLING DEVICE AND MICROPROCESSOR CONTROL

Modern HPLC is adequately provided with complete data

handling devices. Thousands of samples routinely analysed in Quality Assurance

Laboratories in Pharmaceutical Industries/Bulk Drug Industries etc. are duly

processed and the data stored in the computerised data-handling devices. Each

stored data may be retrieved from the memory of the computerised device with

the flick of a finger, as and when needed, in the form of print-out.

Microprocessor based analytical equipments is no longer

an uncommon phenomenon towards the mod-ernization, automation, and above all

the ease of function and handling of sophisticated devices, for instance : a

microprocessor scans the array of diodes many times a second in a ‘diode array detector’ ; a

microproces-sor does the temperature programming of a constant temperature

chamber of HPLC unit.

Related Topics