Chapter: Linear Integrated Ciruits : Application of ICs

Generating Multiple Outputs

Generating Multiple Outputs:

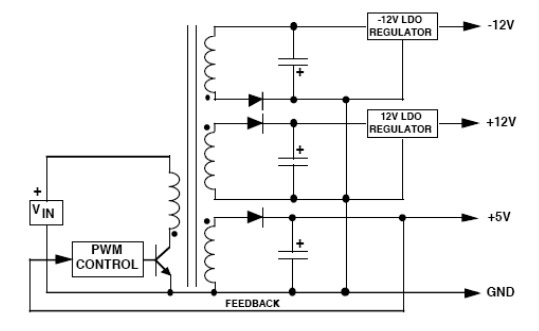

Another

big advantage of a Flyback is the capability of providing multiple outputs .In

such applications, one of the outputs (usually the highest current) is selected

to provide PWM feedback to the control loop, which means this output is

directly regulated. The other secondary winding(s) are indirectly regulated, as

their pulse widths will follow the regulated winding. The load regulation on

the unregulated secondaries is not great (typically 5 - 10%), but is adequate

for many applications. If tighter regulation is needed on the lower current

secondaries, an LDO post-regulator is an excellent solution. The secondary

voltage is set about 1V above the desired output voltage, and the LDO provides

excellent output regulation with very little loss of efficiency.

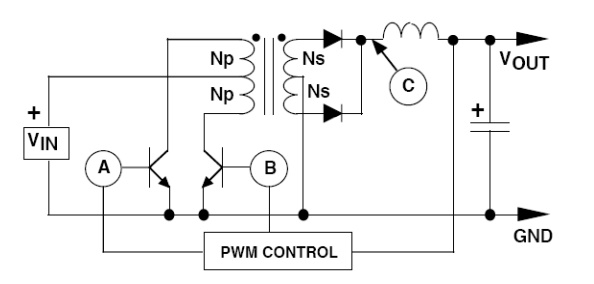

The

Push-Pull converter uses two to transistors perform DC-DC conversion. The

converter operates by turning on each transistor on alternate cycles (the two

transistors are never on at the same time). Transformer secondary current flows

at the same time as primary current (when either of the switches is on). For

example, when transistor "A" is turned on, the input voltage is

forced across the upper primary winding with dot-negative polarity. On the

secondary side, a dot-negative voltage will appear across the winding which

turns on the bottom diode. This allows current to flow into the inductor to

supply both the output capacitor and the load. When transistor "B" is

on, the input voltage is forced across the lower primary winding with

dot-positive polarity.

The same

voltage polarity on the secondary turns on the top diode, and current flows

into the output capacitor and the load. An important characteristic of a Push-Pull

converter is that the switch transistors have to be able the stand off more

than twice the input voltage: when one transistor is on (and the input voltage

is forced across one primary winding) the same magnitude voltage is induced

across the other primary winding, but it is "floating" on top of the

input voltage. This puts the collector of the turned-off transistor at twice

the input voltage with respect to ground. The "double input voltage"

rating requirement of the switch transistors means the Push-Pull converter is

best suited for lower input voltage applications. It has been widely used in

converters operating in 12V and 24V battery-powered systems.

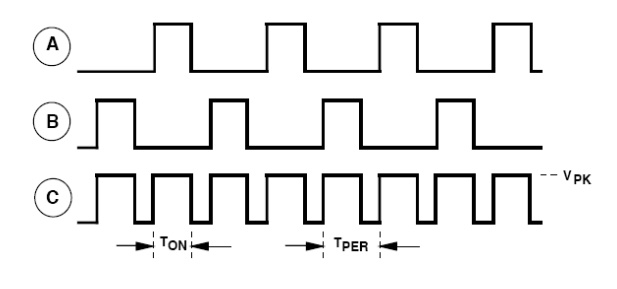

Figure

shows a timing diagram which details the relationship of the input and output

pulses. It is important to note that frequency of the secondary side voltage

pulses is twice the frequency ofoperation of the PWM controller driving the two

transistors. For example, if the PWM control chip was set up to operate at 50

kHz on the primary side, the frequency of the secondary pulses would be 100

kHz. This highlights why the Push-Pull converter is well-suited for low voltage

converters. The voltage forced across each primary winding (which provides the

power for conversion) is the full input voltage minus only the saturation

voltage of the switch. If MOS-FET power switches are used, the voltage drop

across the switches can be made extremely small, resulting in very high

utilization of the available input voltage. Another advantage of the Push-Pull

converter is that it can also generate multiple output voltages (by adding more

secondary windings), some of which may be negative in polarity. This allows a

power supply operated from a single battery to provide all of the voltages

necessary for system operation. A disadvantage of Push-Pull converters is that they require very good matching of the switch transistors to

prevent unequal on times, since this will result in saturation of the

transformer core (and failure of the converter).

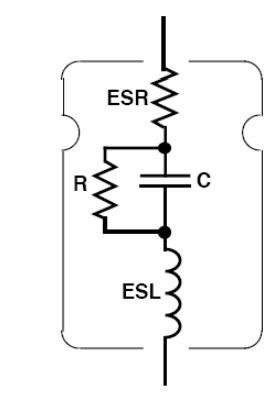

Output Capacitor ESR effects:

The

primary function of the output capacitor in a switching regulator is filtering.

As the converter operates, current must flow into and out of the output filter

capacitor. The ESR of the output capacitor directly affects the performance of

the switching regulator. ESR is specified by the manufacturer on good quality

capacitors, but be certain that it is specified at the frequency of intended

operation.

General-purpose

electrolytes usually only specify ESR at 120 Hz, but capacitors intended for

high-frequency switching applications will have the ESR guaranteed at high

frequency (like 20 kHz to 100 kHz). Some ESR dependent parameters are: Ripple

Voltage: In most cases, the majority of the output ripples voltage results from

the ESR of the output capacitor. If the ESR increases (as it will at low

operating temperatures) the output ripple voltage will increase accordingly.

Efficiency:

As the switching current flows into and out of the capacitor (through the ESR),

power is dissipated internally. This "wasted" power reduces overall

regulator efficiency, and can also cause the capacitor to fail if the ripple

current exceeds the maximum allowable specification for the capacitor.

Loop

Stability: The ESR of the output capacitor can affect regulator loop stability.

Products such as the LM2575 and LM2577 are compensated for stability

assumingthe ESR of the output capacitor will stay within a specified range.

Keeping the ESR within the "stable" range is not always simple in

designs that must operate over a wide temperature range. The ESR of a typical

aluminum electrolytic may increase by 40X as the temperature drops from 25°C to

-40°C.

In these

cases, an aluminum electrolytic must be paralleled by another type ofcapacitor

with a flatter ESR curve (like Tantalum or Film) so that the effective ESR

(which is the parallel value of the two ESR's) stays within the allowable

range. Note: if operation below -40°C is necessary, aluminum electrolytics are

probably not feasible for use.

Related Topics