Chapter: Pharmaceutical Biotechnology: Fundamentals and Applications : Gene Therapy

General Anatomy and Production of a Gene Transfer Vector

General Anatomy and Production of a Gene Transfer Vector

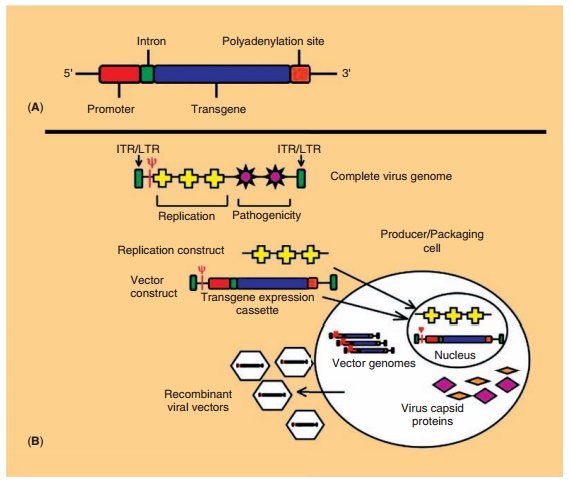

A gene-based medicine typically consists of an expression cassette made

of cDNA flanked by apromoter on the 50 side and

a transcription stop and polyadenylation site on the 30 side (Fig. 4A). This is incorporated into a DNA plasmid or a

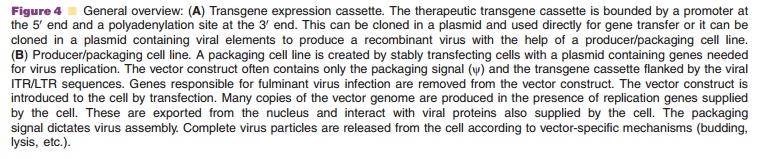

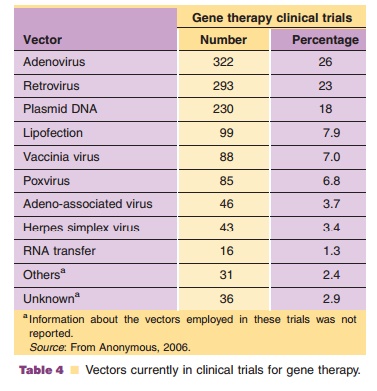

recombinant virus, based upon therapeutic requirements (Tables 4 and 5). The

genes responsible for the pathogenicity of viral vectors are removed and

replaced with the expression cassette in order to limit virus reproduc-tion and

fulminant disease. In many vectors, all that remains of the original virus

genome are long terminal repeats (LTRs), 5 and 3 terminal regions of the virus

that control transcription for RNA viruses or inverted terminal repeats (ITRs),

identical but oppo-sitely oriented sequences that drive DNA replication and

stabilize the genome of DNA viruses. The packaging signal (y), responsible for virus assembly, is also kept intact. Genes for

replication are supplied in trans by a producer/packaging cell line

for large-scale production (Fig. 4B). Virus biology will dictate the manner in

which the recombinant vector is produced. Careful thought must go into the

design of a packaging cell line in order to minimize overlap between sequences

in the virus genome and the cell that dictate replication and/or pathogenesis.

If sub-stantial overlap exists, these sequences can inadver-tently be

incorporated in the recombinant virus by homologous recombination. Replication

competent (pathogenic) virus particles will then be produced with replication

deficient particles. Preparations are often screened for replication competent

virus (RCV) prior to clinical use. After production and harvest from a

packaging cell line, recombinant vectors are purified, quantified and/or

titered. Traditionally, purification strategies have relied upon density

gradient ultracentrifugation to separate the vector from cellular proteins.

This process is laborious, difficult to scale up and can reduce the effective

titer of stock preparations by disrupting vector structure (Shamlou, 2003;

Burova, 2005). Advances in column chromatography have mitigated these issues

for many vectors, allowing them to be grown and purified to high concentrations

needed for human use.

Given the diversity of diseases suitable for gene therapy, it is

apparent that there can be no single vector that is appropriate for all gene

transfer applications. Thus, selection of an appropriate vector for gene

delivery requires careful consideration of a number of factors including: (a) size limitations for transgene cassettes, (b) transduction efficiency in therapeutic target (ability to infect

dividing and/or non-dividing cells, appropriate receptors present on target

cells), (c) duration of gene expression required for treatment (long-term vs.

transient expression, integrating vs. non-integrating vectors), (d) necessity of temporal gene expression (inducible expression vs.

constitutive expression), (e) maximum threshold of

vector-induced immune response and toxicity

Related Topics