Chapter: Mechanical : Computer Integrated Manufacturing

Flexible manufacturing system - FMS

Flexible manufacturing system - FMS

A flexible manufacturing system

consists of a group of processing stations, interconnected by means of a

automated material handling and storage systems, and controlled by an

integrated computer system.

FMS Flexibility:

The three capabilities that a manufacturing system must

process in order to the flexible

1. The

ability to identify and distinguish among the different incoming part or

product styles processed by the system.

2. Quick

changeover of operating instructions.

3. Quick

changeover of physical setup. Flexibility is an attribute that applies to both

manual and automated systems. In manual systems the human workers are often the

enables of the systems flexibility.

Types of flexibility;

The flexibility allows a mixed

model manufacturing system to cope with level of variation in part or product

style without interruptions in production for changeover between models. It is

generally a desirable feature of a manufacturing system.

The

feature of flexibility is broadly classified in to following ways

1. Machine

flexibility

2. Part

flexibility

3. Route

flexibility

4. Volume

flexibility

5. Man

flexibility.

FMS technology is approaches to

simultaneously manufacture different parts in the shortest time possible, with

the highest quality and at the lowest costs possible. To do this a maximum of

management of management information must be available for the FMS host to work

with. When this is achieved there are several types of flexibility available;

to an FMS user.

1. FMS user

flexibility

2. FMS

supplier flexibility.

1. FMS user

flexibility

The first area is that in which the FMS user is interested.

This most important area.

The available flexibilities are

provided for the FMS user to be able to satisfy the demands of their customers.

2. FMS supplier flexibility.

The second type of flexibility

concerns the method of applying FMSs.this is of extreme interest to the FMS

host supplier. Every FMS application’s different, and no. of

FMS supplier can start from scratch to supply a FMS host

solution every time for each new

FMS user. A supplier’s solution need to be flexible

enough to integrate the different machine types in to different FMS

configurations and layouts for different product mixes.

1. Components of FMS systems;

·

Workstations

·

Material handling and storage

·

Computer control system

·

Human resources

1. Workstations

The first element in the FMS is work stations; it may,

·

Load/unload stations

·

Machining stations

·

Other processing stations

·

Assembly

2. Material

handling and storage systems

For the belowmentioned functions are the material handling

device

·

Random, independent movement of workparts between

stations.

·

Handle a variety of workpart configurations.

·

Temporary storage.

·

Convenient access for loading and unloading

workpartcontrol.s.

·

Compatible with computer

The material handling is classified in ot two types they are,

§ Primary

material handling

§ Secondary

material handling

The material handling function in a FMS is often shared

between two systems:

1. Primary

handling system - establishes the basic layout of the FMS and is

responsible for moving work parts between stations in the system.

2. Secondary

handling system - consists of transfer devices, automatic pallet changers,

and similar mechanisms located at the workstations in the FMS.

3. Computer

control system

§ Workstation

control

§ Distribution

of control instructions to workstations

§ Production

control

§ Traffic

control

§ Shuttle

control

§ Work

piece monitoring

§ Tool

control

§ Performance

monitoring and reporting

§ Diagnostics

4. Human

resources

For loading and unloading the materials in the

machines and for the maintenance works the human resource are required in the

flexible manufacturing system.

2. Benefits

of FMS

The

various benefits are listed below,

·

Higher machine utilization

·

Reduced work in process

·

Lower manufacturing lead time

·

Greater flexibility in production scheduling.

3. Types of

FMS;

·

Flexible manufacturing module (FMM)

·

Flexible manufacturing cell (FMC)

·

Flexible manufacturing group (FMG)

Flexible fabrication-machining-assembly system (FFMAS)

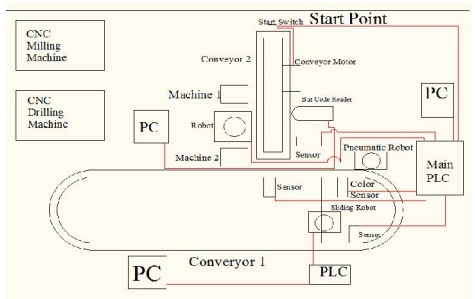

FMS layout

§ In-line

layout

§ Loop

layout

§ Ladder

layout

§ Open

field layout

§ Robot

centered layout

Glossary;

§ Production

Planning and Control - PPC

§ Master

Production Planning - MPP

§ Manufacturing

Requirements Planning - MRP

§ Manufacturing

Resource Planning - MRPII

§ Factory

Data Collection - FDC

§ Flexible

manufacturing module - (FMM)

§ Flexible

manufacturing cell - (FMC)

§ Flexible

manufacturing group - (FMG)

§ Flexible

fabrication-machining – FFM

§ Automated

Guided Vehicle – AGV.

Related Topics