Chapter: Mechanical : Computer Integrated Manufacturing : Components of CIM

Important Questions and Answers: Components of CIM

COMPONENTS OF CIM

1. CIM

Computer-integrated manufacturing

(CIM) is the manufacturing approach of using computers to control the entire

production process.

CIM is the integration of the

total manufacturing enterprise through the use of integrated systems and data

communication coupled with new managerial philosophies that improve

organizational and personnel efficiency.

Computer integrated manufacturing

is defined as the effective use of computers to design the products, plan the

production ,control the operations and perform the various business related

functions needed in a manufacturing firm.

2. What is the main objective of CIM?

·

The main aim of CIM is to use the advanced

information processing technology into all areas of manufacturing industry in

order

·

To make the total process more productive and

efficient;

·

increase product reliability;

·

Decrease the cost of production and maintenance

relating to the manufacturing system as well as to the product; and

·

Reduce the number of hazardous jobs and

3. Automation.

Automation may be defined as the

process of having machines follow a predetermined sequence of operations with

little or no human labor, using specialized equipment and devices that perform

and control manufacturing processes.

4. ‘Islands of automation

The individually automated

workstations or processes are called islands of automation. In other words the

term ‘islands

of automation’ represents the various

technologies that facilitate

manufacturing automation in isolation, without having integrated with other

manufacturing technologies.

5. Difference

between CAD, CAM AND CIM

·

CAD/CAM involves the use of computers to make

Design and Manufacturing more profitable.

·

Parts of CIM use CAD/CAM techniques and products

to try and make the factory fully connected using computers.

·

The essential difference is CAD/CAM provides the

tools, CIM is the philosophy which is used when organizing the computers,

programs, etc. and all the information that flows between them.

·

CIM focuses on connecting the various CAD/CAM

modules.

6. Computer-aided

technologies

·

Computer-aided technologies (CAx) is a broad term

that means the use of computer technology to aid in the design, analysis, and

manufacture of products.

·

Advanced CAx tools merge many different aspects of

the product lifecycle management (PLM), including design, finite element

analysis (FEA), manufacturing, production planning, product

·

Computer-aided design (CAD)

·

Computer-aided engineering (CAE)

·

Computer-aided industrial design (CAID)

·

Computer-aided manufacturing (CAM)

·

Computer-aided requirements capture (CAR)

·

Computer-aided rule definition (CARD)

·

Computer-aided rule execution (CARE)

·

Computer-aided software engineering (CASE)

·

Computer-assisted surgery (CAS)

·

Computer-aided surgical simulation (CASS)

·

Computational fluid dynamics (CFD)

·

Component information system (CIS)

·

Computer-integrated manufacturing (CIM)

7. CIM

system – Hardware & Software.

·

CIM Hardware consists of manufacturing equipments

and Computer related hard ware with the office equipment.

·

CIM Software consists of computer programs to

carry out the various functions and transfer the data from various areas of the

industry.

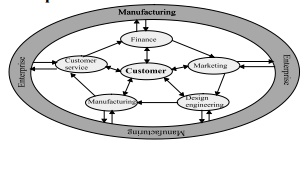

8.CIM Wheel or CIM

Components:

Distinct

components of CIM wheel

·

Manufacturing / Human resource management

·

Marketing

·

Strategic planning

·

Finance

·

Product and process design and planning

·

Manufacturing planning and control

·

Factory automation

9. Computer

communication network in CIM

Communication in the nervous systems

of CIM and this is an integral part of CIM.

·

The development in communication / network

engineering have made implement of CIM easier that before.

10.

What are the various communication needs of

CIM?

·

The information need for manufacturing in a

company requires as follows.

·

Person-to-person, computer-to-computer,

machine-to-machine, person to computer or computer to person, person to machine

or machine to person, computer to machine or machine to computer

11.

What are the fundamental needs of computer

communications?

·

Data: entities that convey meaning

·

Information: the content or interpretation of data

·

Signals: electric or electromagnetic encoding of

data

·

Signaling: the act of propagating the signal along

a medium

·

Transmission: propagating of data by processing of

signals

12.

What are the nine major elements of CIM

systems?

Marketing, Product design, Planning, Purchase,

Manufacturing engineering, Factory automation hardware, warehousing, finance,

and Information management

13.

Data Transmission Methods.

·

Serious & Parallel Communications.

·

Synchronous & Asynchronous methods.

·

Simplex & Duplex methods.

15. Types of Computer networks

The computer networks can be classified into four

categories depending upon the physical separations of the communication

devices.

·

Miniature - <50m

·

Small - <500m

·

Medium - <1km

·

Large - >1km

- WAN & LAN.

16.

Local Area Network;

Local Area Network is intended to serve a number

of users who are physically located close together.

17. Wide Area Network;

Wide Area Network more like to

telephone network, tying different people in different buildings, cities or

even countries.

18. Network Topologies.

There are several commonly used

network topology or ways of routing the interconnections. It classified as

Star, Ring, Bus topologies.

19. Seven Layers of OSI

model.

The

protocol layers are;

1. Physical

layer,

2. Data link

layer,

3. Network

layer,

4. Transport

layer,

5. Session

layer,

6. Presentation

layer,

7. Application

layer.

20. Components of LAN;

The

various components of LAN are listed below;

·

Computers,

·

Network interface card,

·

Network cable,

·

Network server,

·

Central mass storage.

21.Database

·

The data base can be defined as a collection

data in a single location defined to be used by different programmers for a

variety of applications.

·

The database of a company will include data

required for various departments like design, purchase, manufacturing

technology, personnel, marketing and sales, finance inventory etc.

22.

Differentiate data and information.

The data refers to the value stored in the

database and information to the meaning as understood by the user.

23. Network Topologies.

There are several commonly used

network topology or ways of routing the interconnections. It classified as

Star, Ring, Bus topologies.

Star

network communications

The star network consists of a

central control station to which each of the individual devices or user

stations are connected. To send messages from one workstation to the other is

through the central station.

Ring network communication

In ring network communication the

individual stations are connected in a continuous ring .Each station has a neighboring

station on either side. To communicate from one station to other, the message

must be relayed from station to station until it finally arrives at its

designated destination station.

Bus network communication

The bus network consists of a

single main transmission line to which the individual devices are attached. Any

device or station can communicate with any other device in the network by

sending its message through the bus with the address of the desired recipient.

Reasons

for having database for the company

·

Redundancy can be reduced

·

Inconsistency can be avoided

·

The data can be shared

·

Standards can be enforced

·

Security restrictions can be applied

·

Integrity can be maintained

·

Conflicting requirements can be balanced

Different

types of design data related to CIM

·

Standards-national, international, trade or

company standards

·

Material specifications and properties

·

Design theories and rules of thumb.

·

Data based on experience

·

Test results of products and proto types

·

Service feedback

·

Results of analysis of the product

·

Data’s on competitor’s product.

Related Topics