Chapter: Mechanical : Computer Integrated Manufacturing : Computer Aided Design

Geometric modeling

Geometric modeling

Geometric modeling involves the

use of a CAD system to develop a mathematical description of the geometry of an

object. The mathematical description, called a geometric model is contained in

computer memory. These operations include creating new geometric models from

basic building blocks available in the system. Geometric modeling is a branch

of applied mathematics and computational geometry that studies methods and

algorithms for the mathematical description of shapes.

The shapes studied in geometric

modeling are mostly two- or three-dimensional, although many of its tools and

principles can be applied to sets of any finite dimension. Today most geometric

modeling is done with computers and for computer-based applications.

Two-dimensional models are important in computer typography and technical

drawing. Three-dimensional models are central to computer-aided design and

manufacturing (CAD/CAM), and widely used in many applied technical fields such

as civil and mechanical engineering, architecture, geology and medical image

processing.

Geometric models are usually

distinguished from procedural and object-oriented models, which define the

shape implicitly by an opaque algorithm that generates its appearance. They are

also contrasted with digital images and volumetric models which represent the

shape as a subset of a fine regular partition of space; and with fractal models

that give an infinitely recursive definition of the shape.

However, these distinctions are

often blurred: for instance, a digital image can be interpreted as a collection

of colored squares; and geometric shapes such as circles are defined by

implicit mathematical equations. Also, a fractal model yields a parametric or

implicit model when its recursive definition is truncated to a finite depth.

Geometric modeling techniques;

These are

various types of geometric models used in CAD,

·

Based on the dimensioning, - Two dimensional

modeling, - Three dimensional modeling.

·

Based on the modeling,

-

Wire frame modeling,

-

Surface modeling,

-

Solid modeling.

2D Vs 3D;

2D models are best utilized for design problems,

such as flat objects and layouts of building.

3D models are capable of modeling an object in

three dimensional according to user instructions.

This is helpful in conceptualizing the object

since in true 3D models can be displayed in various views and form different

angles.

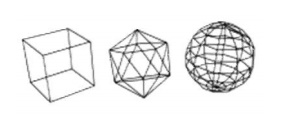

1.

Wire-frame modeling technique in CAD

A wire-frame model is a visual

presentation of a three-dimensional (3D) or physical object used in 3D computer

graphics. It is created by specifying each edge of the physical object where

two mathematically continuous smooth surfaces meet, or by connecting an

object's constituent vertices using straight lines or curves. The object is

projected onto a display screen by drawing lines at the location of each edge.

The term wire frame comes from designers using metal wire to represent the

three-dimensional shape of solid objects. 3D wire frame allows to construct and

manipulate solids and solid surfaces. The 3D solid modeling technique

efficiently draws higher quality representations of solids than the

conventional line drawing.

Using a wire-frame model allows

visualization of the underlying design structure of a 3D model. Traditional

two-dimensional views and drawings can be created by appropriate rotation of

the object and selection of hidden line removal via cutting planes. Since

wire-frame renderings are relatively simple and fast to calculate, they are

often used in cases where a high screen frame rate is needed (for instance,

when working with a particularly complex 3D model, or in real-time systems that

model exterior phenomena). When greater graphical detail is desired, surface

textures can be added automatically after completion of the initial rendering

of the wire frame. This allows the designer to quickly review Chan solids or

rotate the object to new desired views without long delays associated with more

realistic rendering.

The wire frame format is also

well suited and widely used in programming tool paths for direct numerical

control (DNC) machine tools. Hand-drawn wire-frame-like illustrations date back

as far as the Italian Renaissance.[1] Wire-frame models were also

used extensively in video games to represent 3D objects during the 1980s and

early 1990s when properly filled 3D objects would have been too complex to

calculate and draw with the computers of the time. Wire-frame models are also

used as the input for computer-aided manufacturing (CAM). There are mainly

three types of 3D CAD models. Wire frame is one of them and it is the most

abstract and least realistic. Other types of 3D CAD models are surface and

solid. This method of modeling consists of only lines, points and curves

defining the edges of an object.

Advantages of Wireframe Modeling;

·

Simple to construct,

·

Designer needs little training.

·

It needs less memory space,

·

It takes less manipulation time,

·

It is best suitable for manipulation as

orthographic, isometric and perspective views.

B-rep – Boundry

representation;

B-rep construction consists of entering all boundary edge for

all surfaces. This is similar or copying an engineering drawing into the

computer, line by line,

surface by surface, with one important qualification. The

lines must be entered and surfaces oriented in such a way that they create

valid volumes.

CSG –

Constructive Solid Geometry;

CSG technique uses Boolean combinations or

primitives solids to build a part. The Boolean operations are addition (+),

subtraction (-), as illustrated in three dimensions.

2. Surface modeling

Surface

modeling is defining an object’s exterior with an infinitesimally thin skin.

This skin is created by lofts,

sweeps, and NURBS curves - i.e. sculptured surfaces with lots of curvature. The

surfaces are either defined by poles or guide curves. A surface is

considered a solid only when it is completely enclosed. It is

used to make technical surfaces

(e.g. air plane wing) or aesthetic surfaces (e.g.

car’s hood).

It was developed for the

aerospace and automotive industries in the late 70s. Rhinoceros 3D and Alias

Studio Tools are examples of a surface modeling programs. It is generally

considered more difficult than solids modeling, but the models are more robust because

the programs aren’t generally feature based. Later changes have to modify the existing

geometry as opposed to just editing the original feature, which is more

difficult but keeps the model from collapsing when one feature interferes with

another.

3. Solid modeling technique in CAD

Solid modeling (or modelling) is

a consistent set of principles for mathematical and computer modeling of

three-dimensional solids. Solid modeling is distinguished from related areas of

geometric modeling and computer graphics by its emphasis on physical fidelity.[1]

Together, the principles of geometric and solid modeling form the foundation of

computer-aided design and in general support the creation, exchange,

visualization, animation, interrogation, and annotation of digital models of

physical objects.

The use of solid modeling

techniques allows for the automation of several difficult engineering

calculations that are carried out as a part of the design process. Simulation,

planning, and verification of processes such as machining and assembly were one

of the main catalysts for the development of solid modeling. More recently, the

range of supported manufacturing applications has been greatly expanded to

include sheet metal manufacturing, injection molding, welding, pipe routing

etc.

Beyond

traditional manufacturing, solid modeling techniques serve as the foundation

for rapid prototyping, digital data archival and reverse engineering by

reconstructing solids from sampled points on physical objects, mechanical

analysis using finite elements, motion planning and NC path verification,

kinematic and dynamic analysis of mechanisms, and so on.

A central problem in all these

applications is the ability to effectively represent and manipulate

three-dimensional geometry in a fashion that is consistent with the physical

behavior of real artifacts. Solid modeling research and development has

effectively addressed many of these issues, and continues to be a central focus

of computer-aided engineering.

Advantages of Solid Modeling;

·

It is complete and unambiguous.

·

Suitable for automated applications like creating

part program without much human involvement.

4.Solids vs. Surface

Modeling;

Computer aided design

(CAD) isn’t like a car in that you can use it pretty well even if

you don’t know how it works. It pays to know what happening ‘under the hood’

when

using CAD. It is important to

know about surface and solids modeling because it does affect the way you

model, and it is important to know if you are switching platforms. It is also

very important to know about for rapid prototyping.

Surfaces

and solids are the underlying math that defines the geometry of the forms

you create. There are three ways to define 3D geometry:

solids, surfaces and wireframes.

Wireframes don’t play much of a role in CAD, but

primarily in digital content creation

(DCC) and gaming. The easiest way

to understand the difference between surface and solids modeling is to think of

a water balloon; the water in the balloon would be solids modeling, while the

latex skin would be surface modeling. Need more of an explanation? No problem.

Solids modeling;

Solids modeling is defining an

object with geometric mass. Solids modeling programs usually create models by

creating a base solid and adding or subtracting from it with subsequent

features. Features such as extrudes, extrude cuts, revolves, radii, chamfers,

etc. Examples of solids modeling programs are Solid works, CATIA, and Pro

Engineer. It was originally developed for machine design, and is used heavily

for engineering with large part assemblies, digital testing and rapid

prototyping.

Surface modeling;

Surface

modeling is defining an object’s exterior with an infinitesimally thin skin.

This skin is created by lofts, sweeps, and NURBS curves - i.e. sculptured surfaces with lots of curvature. The surfaces are either defined by poles or guide curves. A surface is considered a solid only when it is completely enclosed. It is used to make technical surfaces

(e.g. air plane wing) or aesthetic surfaces (e.g.

car’s hood).

It was developed for the aerospace and automotive industries in the late 70s. Rhinoceros 3D and Alias Studio Tools are examples of a surface modeling programs. It is generally considered more difficult than solids modeling, but the models are more robust because the programs aren’t generally feature based. Later changes have to modify the existing geometry as opposed to just editing the original feature, which is more difficult but keeps the model from collapsing when one feature interferes with another.

Related Topics