Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Numerical Control

Engineering Analysis of Numerical Control(NC) Positioning Systems

ENGINEERING ANALYSIS

OF NC

POSITIONING SYSTEMS

The

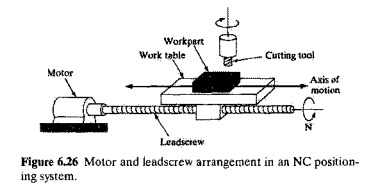

NCpositioning system converts the coordinate axis values in the NC part program

into relative positions of the tool and workpart during processing. Let us

consider the simple positioning system shown in Figure 6.26. The system

consists of a cutting tool and a worktable on which a workpart is fixtured. The

table is designed to move the part relative to the tool. The worktable moves

linearly b)' means of a rotating leadscrew, which is driven by a stepping motor

or servomotor. For simplicity, we show only one axis in our sketch. To provide .~.y capability: the system shown would

be piggybacked on top of a second axis per, pendicular to the first. The

leadscrew bas a certain pitchp (in/thread, mm/thread). Thus, the table mows a

distance equal to the pitch for each revolution. The velocity of the worktable,

which corresponds to the feed rate in a machining operation, is determined by

the rotational speed 01 the leadscrew,

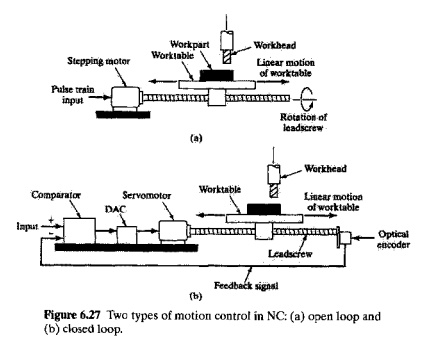

There are two types of positioning systems used

in NC systems: (a) open loop and (b) closed loop, as shown in Figure

6.27. An open-loop system operates without verifying that the actual

position achieved in the move is the same as the desired position. A closed loop control system uses feedback

measurements to confirm that the final position of the worktable is the location specified in the program. Open loop

systems cost less than closedloop systems and are appropriate when the force

resisting the actuating motion is minimal. Closed loop systems are normally

specified for machines that perform continuous path operations such as milling

or turning, in which there are significant forces resisting the forward motion

of the Cuting tool.

Open Loop

Postioning Systems

An

openloop positioning system typically uses a stepping motor to rotate the

leadscrew A stepping motor is driven by a series of electrical pulses, which

are generated by the MCU in an NC system. Each pulse causes the motor to rotate

a fraction of one revolution. called the step angle. The possible step angles

must be consistent with the following relationship:

where ct = step angle (degrees), and n, = the number of step angles for the

motor, which must be an integer. The angle through which the motor shaft

rotates is given by

where Am = angle of

motor shaft rotation (degrees), np == number of pulses received by the

motor. and ct = step angle (degrees/pulse). The

motor shaft is generally connected to the leadscrew through a gear box, which

reduces the angular rotation of the leadscrew. The angle of the leadserew

rotation must take the gear ratio into account as follows'

where A == angle of

leadscrew rotation (degrees), and r g = gear

ratio, defined as the number of turns of the molor for each single turn of the

leadserew. That is,

where x == xaxis

position relative to the starting position (mm, inch), p = pitch of the leadscrew (nun/rev,

in/rev).and Aj360 = number of Ieadscrew revolutions,

The number of pulses required to achieve a specified .rposition increment in a

pointtopoint system can be found by combining the two preceding equations as

follows:

where the

second expression on the righthand side is obtained by substituting n, for 360/ a, which is obtained by rearranging Eq. (6.10).

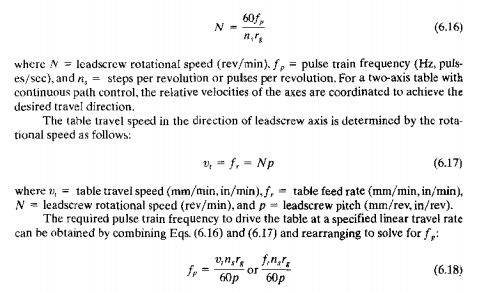

Control

pulses are transmitted from the pulse generator at a certain frequency, which

drives the worktable at a corresponding velocity or feed rate in the direction

of the leadscrew axis. The rotational speed of the leadscrew depends on the

frequency of the pulse train as follows:

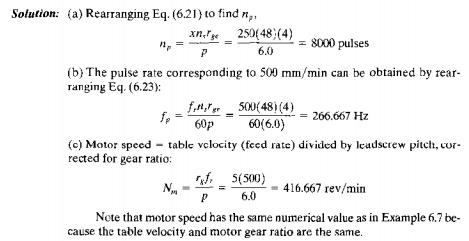

EXAMPLE 6.7 NC

Open-Loop Positioning

The

worktable of a positioning system is driven by a leadserew whose pitch == 6.0 mm. The leadscrew is

connected to the output shaft of a stepping motor through a gearbox whose ratio

ts S: 1 (5 turns of the motor to one turn of the leadscrew). The stepping motor

has 48 step angles. The table must move a distance of 250 mm from its present

position at a linear velocity '" 500 mm/min Determine (a) how many pulses

are required to move the table the specified distance and (b) the required

motor speed and pulse rate to aehieve the desired table velocity,

Solution: (a) Rearranging Eq. (6.14) to

find the teadscrew rotation angle A

corresponding to a distance x = 250 mm,

Closed Loop Positioning

Systems

A

closed-loop NC system, illustrated in Figure 6.27(h). uses servomotors and

feedback measurements to ensure that the worktable is moved to the desired

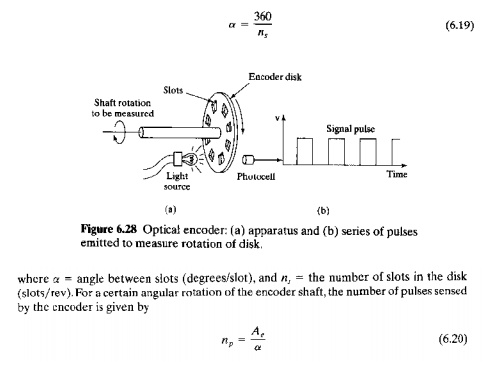

position. A common feedback sensor used for NC (and also for industrial robots)

is the optical encoder, shown in Figure 6.28. An optical encoder consists of a

light source and a photodetector on either side of a disk. The disk contains

slots uniformly spaced around the outside of its face. These slots allow the

light source to shine through and energize the photodetector. The disk is

connected, either directly or through a gear box, to a rotating shaft whose

angular position and velocity are to be measured. As the shaft rotates, the

slots cause the light source to be seen by the photocell as a series of

flashes. The flashes are converted into an equal number of electrical pulses.

By counting the pulses and computing the frequency of the pulse train,

worktable position and velocity can be determined.

The

equations that define the operation of a closedloop NC positioning system are

similar to those for an openloop system. In the basic optical encoder, the

angle between slots in the disk must satisfy the following requirement:

where np = pulse count emitted by the encoder, Ae = angle of rotation of the encoder

shan (degrees), and a = angle between slots, which

converts to degrees per pulse. The pulse count can he used to determine the

linear xaxis position of the

worktable by factoring in the leadscrew pitch and the gear reduction between

the encoder shaft and the leadscrew. Thus,

where np and n, are defined above,p =

leadscrew pitch (mm/rev, in/rev), and r

ge = gear reduction between the

encoder and the Ieadscrew, defined as the number of turns of the encoder shaft

for each single turn of the leadscrew, That is,

The pulse

train generated by the encoder is compared with the coordinate position and

feed rate specified in the part program, and the difference is used by the MCV to drive

a servomotor, which in tum drives the worktable. A digitaltoanalog converter

(Section 5.4) converts the digital signals used by the MeV into a continuous analog current

that powers the drive motor. Closedloop NC systems of the type described here

are appropriate when a reactionary force resists the movement of the table.

Metal cutting machine tools that perform continuous path cutting operations,

such as milling and turning, fall into this category.

EXAMPLE 6,8 NC ClosedLoop PositioninA

An NC

worktable operates by closedloop positioning. The system consists of a

servomotor, leadscrew, and optical encoder. The leadscrew has a pitch = 6.0 rom

and is

coupled to the motor shaft with a gear ratio of 5: I (5 turns of the drive

motor for each turn of the leadscrcw). The optical encoder generates 48

pulses/rev of its output shaft. The encoder output shaft is coupled to the

Ieadscrew with a 4: 1 reduction (4 turns of the encoder shaft for each turn of

the leadscrew). The table has been programmed to move a distance of 250 mm at a

feed rate = 500

mm/min. Determine (a] how many pulses should be received by the control system

to verify that the table has moved exactly 250 mm, (b) the pulse rate of the

encoder, and (c) the drive motor speed that correspond to the specified feed

rate.

Precision in NC Positioning

For

accurate machining or other processing performed by an NC system, the

positioning system must possess a high degree of precision. Three measures of

precision can be defined for an NC positioning system: (I) control resolution.

(2) accuracy, and (3) repeatability.

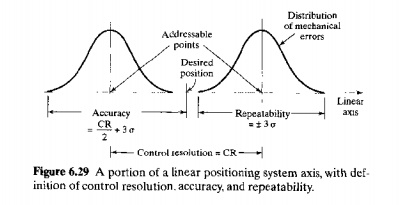

These

terms are most readily explained by considering a single axis of the

positioning system, as depicted in Figure 6.29. Control resolution refers to

the control system's ability to

divide

the total range of the axis movement into closely spaced points that can be

distinguished bythe Men Control resolution is defined as the distance separating two

adjacent addressable points in the axis movement. Addressable points are locations along the axis to which the

worktable can be specifically directed to go. It is desirable for control

resolution to be as small as possible. This depends on limitations imposed by:

(1) the electromechanical components of the positioning system and/or (2) the

number of bits used by the controller to define the axis coordinate location.

A number

of electromechanical factors affect control resolution, including: leadscrew

pitch, gear ratio in the drive system, and the step angle in a stepping motor

for an openloop system or the angle between slots in an encoder disk for a

closedloop system. For an openloop positioning system driven by a stepper

motor, these factors can be combined into an expression that defines control

resolution as follows:

A

desirable criterion is for CR2 <= CR1, meaning that the

electromechanical system is the bmiting factor that determines control

resolution. The bit storage capacity of a modem computer controller is

sufficient to satisfy this criterion except in unusual situations. Resolutions

of 0.0025 mm (0,0001 in) are within the current state of NC technology.

The

capability of a positioning system to move the worktable to the exact location

defined by a given addressable point is limited by mechanical errors that are

due to various imperfections in the mechanical system. These imperfections

include play between the leadscrew and the worktable, backlash in the gears,

and deflection of machine components.

We assume

that the mechanical errors form an unbiased normal statistical distribution

about tle control point whose mean IJ. = D. We further assume that the

standard deviation IT of the distribution is constant

over the range of the axis under consideration. Given these assumptions,

then nearly all of the mechanical errors (99.74%) are contained within ±3r:r of

the control point. This is pictured in figure 1i.29for a portion of the axis range

that in

cludes two control

points.

Let us

now make use of these definitions of control resolution and mechanical error

distribution to define accuracy and repeatability of a positioning system.

Accuracy is defined under 'Worst case conditions in which the desired target

point lies in the middle between two adjacent addressable points. Since the

table can only be moved to one or the other of the addressable points, there

will be an error in the final position of the worktable. This is the maximum

possible positioning error, because if the target were closer to either one of

the addressable points, then the table would be moved to the closer control

point and the error would be smaller. It is appropriate to define accuracy

under this worst case scenario. The accuracy

of any given axis of a positioning system is the maximum possible error that

can occur between the desired target point and the actual position taken by the

system'. in equation form,

where CR = control resolution (mm,in), and o = standard

deviation of the error distribution. Accuracies in machine tools are generally

expressed for a certain range of table travel.tor example.Lo.Ot mm for 250mm

(±OJlOO4 in. for 10 in) of table travel

Repeatability

refers to the capability of the positioning system to return to a given addressable

point that has been previously programmed. This capability can be measured in

terms of the location errors encountered when the system attempts to position

itself at the addressable point. Location errors are a manifestation of the

mechanical errors of the positioning system, which follow a normal

distribution, as assumed previously. Thus, the T{,peatability

of any

given axis of a positioning system is ±3 standard deviations of the mechanical

error distribution associated with the axis. This can be written:

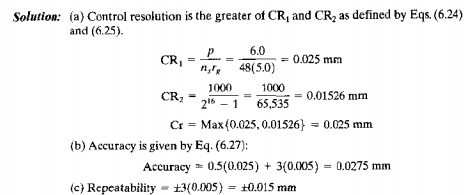

EXAMPLE 6.9 Control Resolution, Accuraq, and Repeatability in NC

Suppose

the mechanical inaccuracies in the openloop positioning system of Example 6.7

are described by a norma! distribution with standard deviation if == 0.005 mm.

The range of the worktable axis is ] 000 mm, and there are 16 bits in th~

binary register used by the digital controller to store the programmed

positron. Other relevant parameters from Example 6.7 are: pitch p = 6.0 mm, gear ratio between motor

shaft and leadscrew r8 = 'i.n, and number of step angles

in the stepping motor ns = 48. Determine (a) the control

resolution. (h) the accuracy. and (c) the repeatability for the positioning

system.

Related Topics