Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Numerical Control

Computer Assisted Part Programming

Computer Assisted Part Programming

Manual

part programming can be time consuming, tedious. and subject to errors for

parts possessing complex geometries or requiring many machining operations.In

these cases, and even for simpler jobs, it is advantageous to use

computer-assisted part programming.A num ber of NC part programming language

systems have been developed to accomplish many of the calculations that the

programmer would otherwise have to do. This saves time and resuits in a

more-accurate and efficient part program. In computer-assisted part programming.

the various tasks are divided between the human part programmer and the

computer.

In

computer-assisted part programming, the machining instructions are written in

English_like statements that are subsequently translated by the computer into

the low-level machine code that can be interpreted and executed by the machine

tool controller When using one of the part programming languages. the two main

tasks of the programmer are: (1) defining the geometry of the workpart and (2)

specifying the tool path and operation-sequence

Defining

the Part Geometry. No matter how complicated the workpart may appear,

it is composed of basic geometric elements and mathematically defined surfaces.

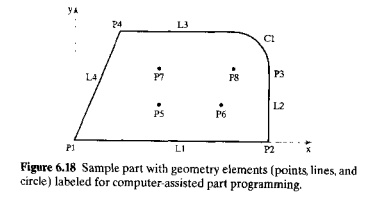

Consider our sample part in Figure 6.18. Although its appearance is somewhat

irregular, the outline of the part consists of intersecting straight lines and

a partial circle. The hole locations in the part can be defined in terms of the

.r. and ycoordinates of their centers. Nearly any component that can be conceived

by a designer can be described by points, straight Jines, planes, circles,

cylinders, and other mathematically defined surfaces. It is the part pro

grammer's

task to identify and enumerate the geometric elements of which the part is

comprised, Each element must be defined in terms of its dimensions and location

relative to

other

elements. A few examples will be instructive here to show how geometric

elements arc defined. We will use our sample part to illustrate, with labels of

geometry elements added as shown in Figure 6.18.

Let us

begin with. the simplest geometric element, a point, The simplest way to define

a point is by means of its

coordinates; for example,

P4 = POINT /35,90,0

where the point

is identified by a symbol (P4), and its coordinates are given in the order

.r, y, z in millimeters (x = 35 mrn, y = 90 mm,

and z = 0). A line can be defined by two points, as in the following:

L1 = LINE/PI, P2

where L1

is the line defined in the statement, and PI and P2 are two previously defined

points. And finallv, a circle can be

defined by its center location and radius:

Cl =

CIRCLE/CENTERP8,RADIUS,30

where Cl

is the newly defined circle. with center at previously defined point PR and radiu's = 30 mm. Our examples are based on

the APT language, which offers many alternative ways to define points, lines.

circles, and other geometric elements. The APT language is described in Section

6.5.4. and a listing of APT word definitions is provided in the Appendixto this

chapter

Specifying

Tool Path and Operation Sequence. After the part geometry has been

defined, the part programmer must next specify the tool path that the cutter

will follow to machine the part. The tool path consists of a sequence of

connected line and arc segments, using the previously defined geometry elements

to guide the cutter. For example, suppose we are machining the outline of our

sample part in Figure 6.18 in a profile milling operation (contouring). We have

just finished cutting along surface Ll in a counterclockwise direction around

the part, and the tool is presently located at the intersection of surfaces LJ

and L2. The following APT statement could be used to command the toolto make a

left lurn from Ll unto 12 and to

cut along L2:

GOLFT/L2,TANTO,CI

The tool

proceeds along surface L2 until it is tangent to (TANTO) circle C1. This is a

continuous path motion command. Pointtopoint commands tend to be simpler: for

example, the following statement directs the tool to go to a previously defined

point Pu

GOTOtPO

A variety

of contouring and pointtopoint motion commands are available in the APT

language

Other Functions. In addition

to defining part geometry and specifying tool path, the programmer must also accomplish various other programming

functions, such as:

naming the program

identifying the machine

tool on which the job will be performed

specifying cutting

speeds and feed rates

designating the cutter

size (cutter radius, tool length,

etc.)

specifying tolerances

in circular interpolation

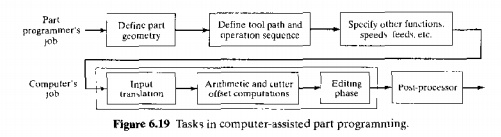

Computer

Tasks in ComputerAssisted Part Programming. The computer's role in

computerassisted part programming consists of the following tasks, performed

more or less in the sequence noted: (1) input translation, (2) arithmetic and

cutter offset computations. (3) editing, and (4) postprocessing, The first

three tasks are carried out under the supervision of the language processing

program. For example, the APT language uses a processor designed to interpret

and process the words, symbols, and numbers written in APT. Other languages

require their own processors. The fourth task, post-processing, re

quires a separate

computer program "I he sequence and relationship of the tasks of the part

programmer and the computer are portrayed in Figure 6.19.

The part

programmer enters the program using APT or some other highlevel part

programming language. The input translation

module converts the coded instructions contained in the program into

computerusable form. preparatory to further processing. In APT, input

translation accomplishes the following tasks: (1) syntax check of the input woe

to identify errors in format, punctuation. spelling, and statement sequence; 12) assigning a sequence number 10

each APT statement in the program; (3) converting geometry elements into a

suitable form for computer processing; and (4) generating an intermediate file

called PROFTL that is utilized in subsequent

arithmetic calculations.

The arithmetic module consists of a set of

subroutines to perform the mathematical computations required to define the

part surface and generate the tool path. including compensation for cutter

offset. The individual subroutines are called by the various statements used in the part programming language, The

arithmetic computations are performed on the PROFIL file. The arithmetic module

frees the programmer from the timecunsuming and errorprone geometry and

trigonometry calculations to concentrate on issues related to workpart

processing. The output of this module is a file called CLFILE, which stands for

"cutter location file." As its name suggests. this file consists

mainly of tool path data.

In editing. the CLFILE is edited. and a new

file is generated called CLDATA. When printed, CLDATA provides readable data on

cutter locations and machine tool operating commands. The machine 1001commands

can be converted to specific instructions during postprocessing. Some of the

editing of CLFILE involves processing of special functions associated with the

part programming language. For example, in APT. one of the special functions is

a COpy command, which provides for copying a tool path sequence that has been

generated in the preceding computations and translating the sequence to a new

location. Another APT instruction processed in the editing phase is lRACUT.

which stands for "transform cutter locations." This instruction

allows a tool path sequence to be transformed from one coordinate system to

another, based on matrix manipulation. Other editing functions are concerned

with constructing tool paths for machines having rotational axes, such as four

and fiveaxis machining centers. The output of the editing phase is a part

program in a format that can be postprocessed for the given machine tool on

which the job will be accomplished

NC

machine tool systems are different. They have different features and

capabilities. Highlevel part programming languages, such as APT, are generally

not intended for only one machine tool type. They arc designed to be genera]

purpose. Accordingly, the final task of the computer in computerassisted part

programming is postprocessing, in

which the CUller location data and machining commands in the CLDATA file arc

converted into lowlevel code that can be interpreted by the NC controller for a

specific machine tool. The output of postprocessing is a part program

consisting of Gcodes, x, yo, and

zcoordinates. S, F,M. and other

functions in word address format. The postprocessor is separate from

the highlevel part programming language. A unique postprocessor must be written

for each machine tool system.

Related Topics