Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Numerical Control

Applications of Numerical Control(NC)

APPLICATIONS OF NC

The operating principle of NC has many applications. There are many industrial operations in which the position of a workhead must be controlled relative to a part or product being processed. The applications divide into two categories: (1) machine tool applications and (2) nonmachine tool applications. Machine tool applications are those usually associated with the metalworking industry. Nonmachine tool applications comprise a diverse group of operations in other industries. It should he noted that the applications are not always identified bv the name "numerical control"; this term is used principally in the rnach(ne tool industry

Machine

Tool Applications

The most

common applications of NC are in machine tool control. Machining was the first

application of NC and it is still one of the most important commercially. In

this section, we discuss NC machine tool applications with emphasis on metal

machining processes.

Machining

Operations and NC Machine Tools. Machining is a manufacturing process

in which the geometry of the work is produced by removing excess material

(Section 2.2.1), By controlling the relative motion between a cutting tool and

the workpiece, the desired geometry is created. Machining is considered one of

the most versatile processes because it can be used to create a wide variety of

shapes and surface finishes.It can be performed ut relatively high production

rates to yield highly accurate parts at relatively low cost.

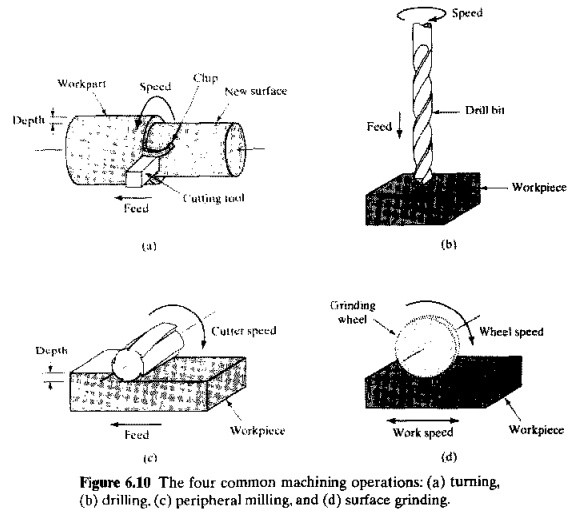

There are four

common types of machining operations: (a)

turning, (b) drilling,

(c) mil1ing,and

(d) grinding. The four operations arc shown in Figure 6.10. Each of the

machining operations is carried out at a certain combination of speed, feed,

and depth of cut, collectively called the cutting

canduions for the operation. The terminology varies somewhat for grinding,

These cutting conditions are illustrated in Figure 6.10 for (a) turning,

(b)

drilling. and (c) milling. Consider milling. The cutting speed is the velocity of the tool (milling cutter) relative

to the work, measured in meters per minute (feet per minute). This is usually

programmed into the machine as a spindle rotation speed (revolutions per

minute). Cutting speed can be converted into spindle rotation speed by means of

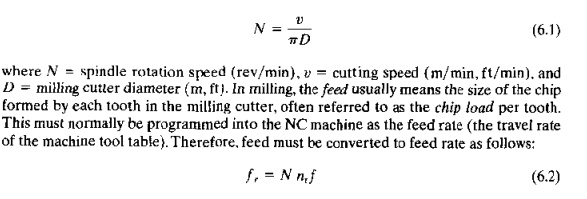

the following equation:

where fr = feed rate (mm/min , in/ min)N = rotational speed {rev/min),n, = number of teeth on the milling

cutter. and f = feed

(mmj'tooth. in/tooth]. For a turning operation, feed is defined as the lateral

movement.of the cutting tool per revolution of the workpiece, so the unns are

millimeters per revolution (inches per revolution). Depth of cut is the distance the tool penetrates below the original

surface of the work (mm, in). These are the paramet~rs that must be controlled

during the operation of an NC machine through motion or position commands in

the part program

Each of

the four machining processes is traditionally carried out on a machine tool

designed to perform that process. Turning is performed on a lathe, drilling is

done on a drill

press,

milling on a milling machine, and so on. The common NC machine tools are listed in the

tollcw.ng along with their typical features:

NC lathe, either

horizontal or vertical axis. Turning requires twoaxis, continuous path control,

either to produce a straight cylindrical geometry [called straight turning) or

to create a profile (contour turning).

NC boring

mill, horizontal and vertical spindle. Boring is similar to turning. except

that an internal cylinder is created

instead of an external cylinder. The operation requires continuous path,

twoaxis control.

NC drill

press. These machines use pointtopoint control oftbe workhead (spindle containing

the drill bit) and two axis (xy) control of the worktable. Some

NC drill presses have turrets containing six or eight drill bits. The turret

position is programmed under NC control. thus allowing different drill bits to

be applied to the same workpert during the machine cycle without requiring the

machine operator to manually change the tool.

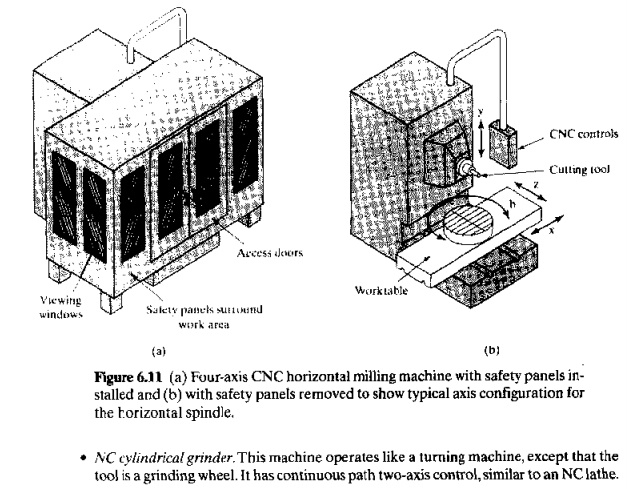

NC milling machine. Milling

machines require continuous path control to perform straight cut or contouring operations. Figure 6.11 illustrates the

features of a fouraxis milling machine.

Numerical

control has had a profound influence on the design and operation of machine

tool>. One of the effects has been that the proportion of time spent by the

machine cutting metal is significantly greater than with manually operated machines.

This causes certain components such as the spindle, drive gears, and feed

screws to wear more rapidly. These components must be designed to last longer

on NC machines. Second, the addition of the electronic control unit has

increased the cost of the machine, therefore requiring higher equipment

utilization. Instead of running the machine during only one shift, which is

usually the convention with manually operated machines, NC machines are often

operated during two or even three shifts to obtain the required economic

payback. Third, the increasing cost of labor has altered the relative roles of

the human operator and the machine tool. Consider the role of the operator.

Instead of being the highly skilled worker who controlled every aspect of part

production, the tasks of the NC machine operator have been reduced to part loading and unloading, toolchanging, chip

clearing, and the like Owing to these reduced responsibilities, one operator

can often run two or three automatic rnachines,

The

functions of the machine tool have also changed. NC machines are designed to be

highly automatic and capable of combining several operations in one setup that

formerly required several different machines. They are also designed to reduce

the time can" sumed by the noncutting elements in the operation cycle,

such as changing tools and loading and unloading the workpart. These changes

are best exemplified by a new type of machine

Batch production, NC is

most appropriate for parts produced in small or medium 101 sizes

(batch sizes ranging from as low as one unit up to several hundred units).

Dedrented automation would be uneconomical for these quantities because of the

high fixed cost. Manual production would require many separate machine setups

and would result in higher labor cost longer lead time. and higher scrap rate.

2, Repeat enters. Batches

of the same parts are produced at random or periodic inter" vah. Once I],e NC part program hus been

prcpareo, parts can he economically produced in subsequent batches using the

same part program,

.1. Complex parr geometry. The part

geometry includes complex curved surfaces such as those found on airfoils and turbine blades. Mathematically defined

surfaces such as circles and helixes can also be accomplished with NC. someor

these geometries would he difficult if not irnpossrhl c to achieve accurately

using conventional machine tools.

Much

fIINa! needs to he removed [eomthe workpan, This condition is often

associated with a complex part geometry, The volume and weight of the final

machined part is a relatively small fraction of the starting block. Such parts are common il1 the

aircraft industry to fabricate large structural sections with low weights.

Many seperate machining operation on the port, This applies to parts consisting

of many machined features requiring

different cuttmg tools, such as drilled anoror tapped hole" slots. flats.

and so on, If these operations were machined by a series of manual operauons.

many setups would be needed. The number of setups can usually be reduced

significantly using NC.

The part is expensive. This

factor is often a consequence of one or more of preceding factor, l 4. and

.'1. It can also result from using a highcost starting work material When the

part is expensive. and mistakes in processing would be costly. the use ofNC

helps to reduce rework and scrap losses

Punch:

presses for sheet metal hole punching. The twoaxis NC operation is similar to that of a drill press except that holes

are produced by punching rather than by drilling.

Presses for sheet

metal bending. Instead of cutting sheet metal, these systems bend sheet metal according to programmed

commands.

Welding

machines. Both spot welding and continuous arc welding machines are available with

automatic controls based on NC.

Thermal

cutting machines, su<.:has oxyfuel cutting, laser cutting, and

plasma arc cutting. The stock is usually flat; thus, twoaxis control is

adequate. Some laser cutting machines can cut holes in preformed sheet metal stock,

requiring fourorfive axis control.

Tube

bending mllchines.Automatic tube bending machines are

programmed to control the location (along the length of the tube stock) and the

angle of the bend. Important applications include frames for bicycles and motorcycles.

Other NC Applications

The

operating principle of NC has a host of other applications besides machine tool

control. However, the applications are not always referred to by the term

"numerical control." Some of these machines with NCtype controls that

position a workhead relative to an object being processed are the following:

Electrical

wire wrap machines. These machines, pioneered by Gardner Denver

Corporation, have been used to wrap and string wires on the back pins of

electrical wiring boards to establish connections between components on the

front of the board. The program of coordinate positions that define the back

panel connections is determined from design data and fed to the wire wrap

machine. This type of equipment has been used by computer firms and other

companies in the electronics industry.

Component insertion machines. This

equipment is used to position and insert com. ponents on an xy plane,

usually a flflt hoard or panel. The program specifics the .rand y~axis

positions in the plane. where the c:ompone?ts are to be located. Component

rnsernon machines find extensive applications for inserting electronic

components into pnntcd circuit boards.

Ma~hincs ~re available for either.throughhole or sur~acemount applications as

well as similar Insertiontype mechanical assembly operations.

Drafting

machine.I.Automated drafting machines serve as one of the output

devices for a CAD/CAM [computer.aided

design/computeraided manufacturing) system. The design of a product and its

components are developed on the CAD/CAM system. Design iterations arc developed

on the graphics monitor rather than on a me chanica! drafting board. When the

design is sufficiently finalized for presentation, the output is plotted on the

drafting machine, basically a high speed xy

plotter.

Coordinate measuring

machine. A

coordinate measuring machine

(CMM) is an in

spection

machine used for measuring or checking di~ensions of a part. The C~ has a probe

that can be manipulated In three axes and Identifies when contact IS made

against a pan surface. The location of the probe tip is determined by the CMM

control unit. thereby indicating some dimension on the part. Many coordinate

measuring machines are programmed to perform automated inspections under NC. We

discuss coordinate measuring machincs in Section 23.4.

Tap"

laying machines for polymer compo5ite5. The workhead of this machine is a

dispenser of uncured polymer matrix composite tape. The machine is programmed

to lay the tape onto the surface of a contoured mold, following a backandforth

and crisscross pattern to huild up a required thickness. The result is a

multilayered panel of the same shape as the mold.

Filament

winding machines for polymer composites, This is similar to the preceding except that a filament is dipped in

uncured polymer and wrapped around a rotating pattern of roughly cylindrical

shape

Additional applications ofNC include cloth

cutting, knitting, and riveting.

Advantages

and Disadvantages of NC

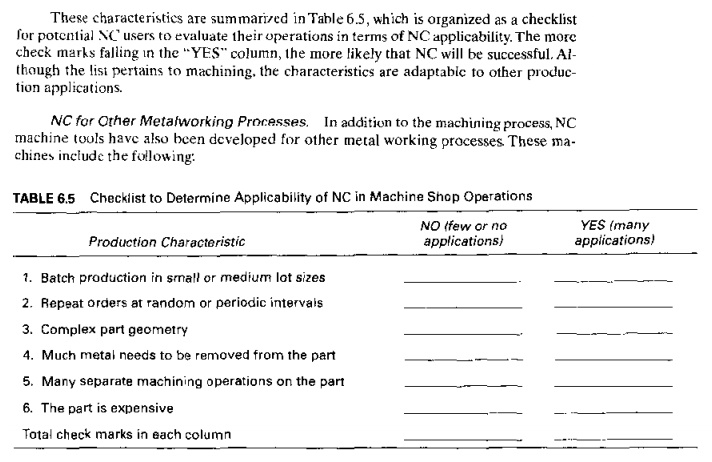

When the

production application satisfies the characteristics in Tahle 6.5, NC yields

many benefits and advantages over manual production methods. These benefits and

advantages translate into economic savings for the user company. However, NC is

a moresophisticated technology than convenuuna! production methods are.ano

there are drawbacks and costs that must be considered to apply the technology

effectively. In this section, we examine the advantages and disadvantages of

NC.

Advantages

of NCo The

advantages generally attributed to NC, with emphasis on machine

tool applications, are the following:

Nonproductive

time is reduced. NC cannot optimize the metal cutting process

itself, hut it does increase the

proportion of time the machine is cutting metal. Reduction in noncutting time

is achieved through fewer setups, less setup time, reduced workpiece handling

time, and automatic tool changes on some NC machines. This advantage translates

into labor cost savings and lower elapsed times to produce parts.

Greater accuracy and repeatability. Compared

with manual production methods, NC reduces

or eljminate~ variations that arc due to operator sk.ill differences, fatigue,

and other factors attributed to inherent human variabilities. Parts are made

closer to nominal dimensions, and there is less dimensional variation among

parts in the batch.

Lower

scrap rates. Because greater accuracy and repeatability are

achieved, and because human errors are reduced during production, more parts

are produced within tolerance. As a consequence, a lower scrap allowance can be

planned into the production schedule. so fewer parts arc made in each batch

with the result that production time IS saved.

Impedion

requlremems arC reduced. Less inspection is needed when NC is used because

parts produced from the same NC part program are virtually identical. Once the

program has been verified, there is no need for the high level of sampling

inspection that IS required when parts are produced by conventional manual

methods.

Except

for tool wear and equipment malfunctions, NC produces exact replicates of the

part each cycle

Morecomplex

part geometries are possible. t\C technology has extended the

range of possible part geometries

beyond what is practical with manual machining methods. This is an advantage in

product design in several ways: (1) More functional features can he devigned

into a single part. thus reducing the total number of parts in the product and

the associated cost of assembly: (2) mathematically defined surfaces can be

fabricated with high precision; and (3) the space is expanded within which the

designer's Imagination com wander to create new part and product geometries.

Engmeenng

,hangf's ':an be

accommodated more 8racefully. Instead of making alterations in

a complex fixture so that the part can be machined to the engineering change.

revisions are made in the NC part program to accomplish the change

Simpler fixtures are NC'

requires simpler fixtures because accurate position" thc toolis accurnplished by the NC machine tool. Tool positioning

does not

Shimer

manufacturing lead times. Jobs can be set up more quickly and fewer setups arc required per part when NC is used.

This results in shorter elapsed time between order release and completion.

Reduced

paris inventory. Because fewer setups are required and job changeovers

are easier and faster. NC permits

production of parts in smaller lot sizes. The economic lot size ISlower in NC

than in conventional batch production. Average parts inventory is therefore

reduced.

Less

fioor.\pm:;erequaed, This results from the fact that fewer NC machines

are requircd to perform the same amount of work compared to the number of

conventiona! machine tools needed. Reduced parts inventory also contributes to

lower floor space requirements.

Operator

skilllevel requirements (Ire reduced. The skill requirements for

operating an NC machine arc generally

less than those required to operate a conventional rna. ~hine tool. Tcndin.g an

NC machi~le tool usually consists only of loading and unloadmg parts and

periodically changing tools. The machining cycle is carried out under program

control. Performing a.comparable machining cycle on ~ conventional machine

requires much more participation by the operator, and a higher level of train.

ing and skill are needed.

Disadvantages

of NC. On the

opposing side, there are certain commitments 10 NC technology that must be made

by the machine shop that installs NC equipment; and these commitments, most of

which involve additional cost to the company, might be seen as disadvantages.

The disadvantages of NC include the following

Higher

utilization of Ne equipment. To maximize the economic benefits

of an NC machine tool. it usually

must he operated multiple shifts. This might mean adding one OJ ]WO exira

shifts to the plaJll'~ normal operations, with the requirement for supervision

and other staff support.

Related Topics