Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Numerical Control

Numerical Control(NC) Part Programming Using CAD/CAM

NC Part Programming Using CAD/CAM

A CAD/CAM system is a computer interactive

graphics system equipped with software is accomplish certain tasks in

design and manufacturing and to integrate the design and manufacturing

functions. We discuss ('AD/CAM in Chapter 24. One of the important tasks

performed on a CAD/CAM system is NC part programming. In this method of part

programming, portions of the procedure usually done by the part programmer are

instead done by the computer. Recall that the two main tasks of the part

programmer in computerassisted programming are (1) defining the part geometry

and (2) specifying the tool path. Advanced CAD/CAM systems automate portions of

both of these tasks.

Geometry

Definition Using CAD/CAM. A fundamental objective of CAD/CAM is to

integrate the design engineering and manufacturing engineering functions.

Certainly one of the important design functions is to design the individual

components of the product. If a CAD/e' AM system is used, a computer graphics

model of each part is developed by the designer and stored in the CAD/CAM data

base. That model contains all of the geometric, dimensional, and material

specificatluns for the part.

When the

same CAD/CAM system, or a CAM system that has access to the same CAD data base

in which the part model resides, is used to perform NC part programming, it

makes little sense to recreate the geometry of the part during the programming

procedure. Instead, the programmer has the capability to retrieve the part

geometry model from storage and to use that model to construct the appropriate

cutter path. The significant advantage of using CAD/CAM in this way is that it

eliminates one of the tirneconsurning steps in computerassisted part

programming: geometry definition. After the part geometry has been retrieved,

the usual procedure is to lahel the geometric elements that will be used during

part programming. These labels are the variable names (symbols) given to the

lines, circJe~ and surfaces that comprise the part. Most systems have the

capacity to automatically label the geometry clements of the part and to

display tbe labels on the monitor. The programmer can then refer to those

labeled elements during tool path construction.

If the NC

programmer does not have access tothe data base, then the geometry of the part

must be defined. This is done by using similar interactive graphics techniques

that the product designer would use to design the part. Points are defined in a

coordinate system using the computer graphics system, lines and circles are

defined from the points, surfaces are defined. and so forth, to construct a

geometric model of the part. The advantage of using the interactive graphics

system over conventional computerassisted part programming is that the

programmer receives immediate visual verification of the definitions being

created. This tends to improve the speed and accuracy of the geometry definition

process

Tool

Path Generation Using CAD/CAM. The second task of the NC

programmer in computerassisted part programming is tool path specification, The

first step in specifying the tool path is La select the cutting tool for the

operation. Most CADICAM systems have tool libraries that

can be called by the programmer to identify what tools arc available in the

tool crib. The programmer must decide which of the available tools is must

appropriate for the operation under consideration and specify it for the tool

path. This permits the tool diameter and other dimensions to be entered

automatically for tool offset calculations. If the desired cutting tool is not

available in the library, an appropriate tool can be specified by rhc

programmer. It then becomes part of the library for future use

The next

step is tool path definition. There are differences in capabilities of the

various CAD/CAM systems, which result in different approaches fur generating

the tool path. The most basic approach involves the use of the interactive

graphics system to enter the motion commands cnebyone.uirnilar to

computerassisted part programming. Individual statements in APT or other part

programming language are entered. and the CAD/CAM system provides an immediate

graphic display of the action resulting from the command. thereby validating

the statement.

A

moreadvanced approach for generating tool path commands is to use one of the

automatic software modules available on the CAD/CAM system. These modules have

been developed to accomplish a number of common machining cycles for milling,

drilling, and turning. They are subroutines in the NC programming package that

can be called and the required parameters given to execute the machining cycle.

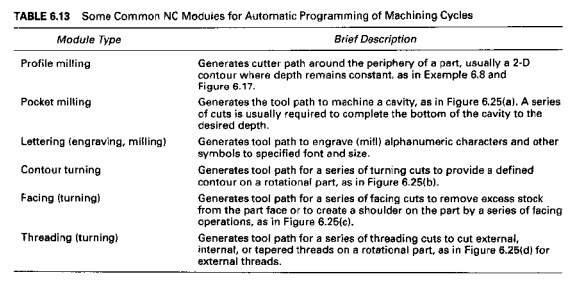

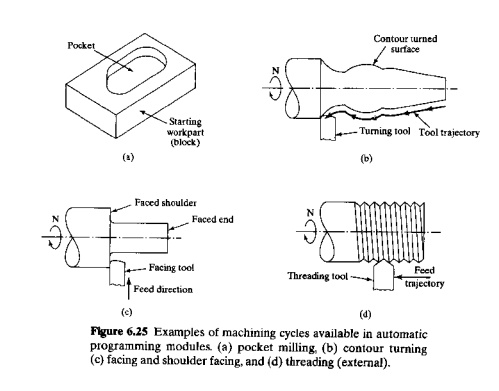

Several of these modules are identified in Table 6.13 and Figure 6.25.

When the

complete part program has been prepared, the CAD/CAM system can provide an

animated simulation of the program for validation purposes.

Computer Automated

Part Programming. In the CAD/CA M approach to NC part programming, several aspects of

the procedure are automated. In the future, it should be possible to automate

the complete NC part programming procedure. We are referring to this fully

automated procedure as computerautomated part programming. Given the geometric

model of a part that has been defined during product design, the

computerautomated system would possess sufficient logic and decisionmaking

capability to accomplish NC part programming for the entire part without human

assistance.

This can

most readily be done for certain NC processes that involve welldefined,

relatively simple part geometries. Examples are pointtopoint operations such as

NC drilling and electronic component assembly machines. In these processes, the

program conststs basically of a series of locations in an xy

coordinate system where work is to be performed [e.g .. holes arc to be drilled

or components are to be inserted). These locations are determined by data that

are generated during product design. Special algorithms can be developed to

process the design data and generate the NC program fur the particular system. "fe contounag

systems will eventually be capable at a similar level of automation. Automatic

programming of this type is closely related to computer-automated process

planning (CAPP), discussed in later pages.

Related Topics