Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Numerical Control

Fundamentals of NC Technology

FUNDAMENTALS OF NC TECHNOLOGY

Fundamentals of NC Technology:

a. Basic Components of an NC System

b. NC Coordinate Systems

c. Motion Control Systems

To

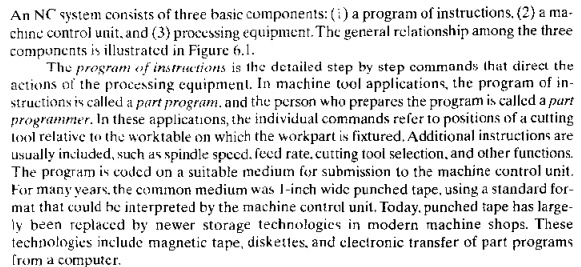

introduce NC technology, we First define the basic components of an NC system.

This is followed by a description of NC coordinate systems in common use and

types of motion controls used in NC.

Basic Components of an NC System

In modern NC technology, the machine controt unit (MeU) consists or a microcomputer and related control hardware that stores the program of instructions and executes it by converting each command into mechanical actions of the processing equipment, one command '1\ a time. The related hardware of the Mel) includes components to interface with the processing equipment and reedbuck control elements. I he MeU also includes one or more reading devices lor entering part programs into memory. The type of readers depends on the stoagc media used for part programs in the machine shop te.g., punched tape reader. magnetic tape reader, floppy disk drive). The MCU also includes control system software.calculation algorithms. and translation software to convert the NC part program into a usable format for the MCl), Because the Mel) is a computer, the term computer numerical control (CNC) is used to distinguish this type of NC from its technological predecessors that wen: based entirely on hardWired electronics. Today, virtually all new MCl)s are based on computer technology; hence. when we refer to NC in this chapter and elsewhere, we mean CNC

The third

basic component of an NC system is the processing

equipment that performs uscruf work, It accornplrshcs the processing sloops

tu transform the stasttng workpiece into a completed parr.It, operation is

directed by the MCl!, which in turn is driven by instruction, contained in the

pun program. In the most common example of NC, machining, the processing

equipment con,is!~ ofthe worktable and spindle as well as the motors and

controls to drive them

NC Coordinate

Systems

To

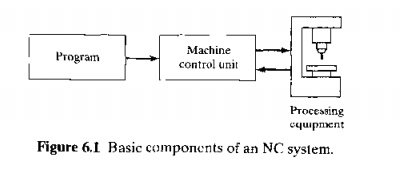

program the NC processing equipment a standard axis system must be defined by

which the position of the workhead relative to the workpart can be specified.

There are two axis systems used in NC, one for flat and prismatic workparts and

the other for rotational parts. Both axis systems are based on the Cartesian

coordinate system.

The axis

system for flat and prismatic parts consists of the three linear axes (x, y, z) in the

Cartesian coordinate system, plus three rotational axes (Q, b, c), as shown in Figure 6.2(a). In most

machine tool applications, the xand yaxes are used to move and position the

worktable to which the part is attached, and the z-axis is used to control the

vertical position of the cutting tool. Such a positioning scheme is adequate

for simple NC applications such as drilling and punching of flat sheet metal.

Programming of these machine tools consists of little more than specifying a

sequence of xy coordinates.

The a, b, and crotational axes specify angular

positions about the X, j, and zaxes, respectively, To

distinguish positive from negative angies, the righthand rule is used. Using the right hand with the thumb

pointing in the positive linear axis direction (+x, +y, or +z), the

fingers of the hand are curled in the positive rotational direction. The

rotational axes can be used for one or both of the following: (1) orientation

of the workpart to present different surfaces for machining or (2) orientation

of the tool or workhead at some angle relative to the part. These additional

axes pennit machining of complex work.pan geometries.

Machine

tools with rotational axis capability generally have either four or five axes:

three linear axes plus one or two rotational axes. Most NC machine tool systems

do not require all six axes.

The

coordinate axes for a rotational NC system are illustrated in Figure 6.2(b).

These systems are associated with NC lathes and turning centersAlthough the

work rotates, this is not one of the controlled axes on most of these tuming

machines. Consequently, the )'_ axis is not used. The path of the cutting tool

relative to the rotating workpiece is defined

in the

.rz plane, where the xaxis is the radial location of the tool, and the zaxis is

parallei to the axis of rotation of the part.

The part

programmer must decide where the origin of the coordinate axis system should be

located. This decision is usually based on programming convenience. For

example, the origin might be located at one of the comers of the part. If the

workpart is sym

metrical,

the zero point might be most conveniently defined at the center of symmetry.

wherever the location. this zero point is communicated to the machine tool

operator. At the beginning of the job, the operator must move the cutting tool

under manual control to some target point

on the worktable, where the tool can be easily and accurately positioned. The

target point has been previously referenced to the origin of the coordinate

axis system by the part programmer. When the tool has been accurately

positioned at the target point, the operator indicates to the MCV where the

origin is located for subsequent tool movements,

Motion

Control Systems

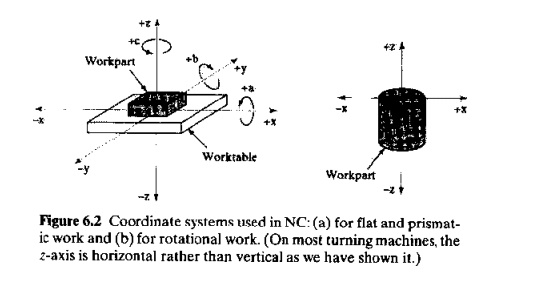

Some NC

processes are performed at discrete locations on the workpart (e.g., drilling

and spot welding). Others are carried out while the workhead is moving (e.g.,

turning and continuous arc welding). If the workhead is moving, it may be

required to follow a straight line path or a circular or other curvilinear

path. These different types of movement are accomplished by the motion control

system, whose features are explained below.

PointtoPoint

Versus Continuous Path Control. Motion control systems for NC (and

robotics, Chapter 7) can be divided into two types: (1) pointtopoint and (2)

continuous path. Pointto·poimsystems,

abo called positioning systems, move

the worktable tu a programmed location without regard for the path taken to get

to that location. Once the move has been completed, some processing action is

accomplished by the workhead at the location. such as drilling or punching a

hole. Thus, the program consists of a series of point locations at which

operations are performed, as depicted in Figure 6.3.

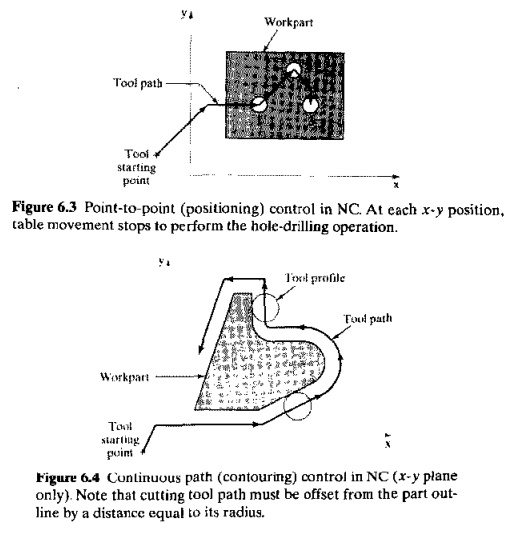

Continuous path systems generally

refer to systems that are capable of continuous simultaneous control of two or more axes. This provides control of

the tool trajectory relative to the workpart. In this case, the tool performs

the process while the worktable is moving, thus enabling the system to generate

angular surfaces, twodimensional curves, or threedimensional contours in the

workpart. This control mode is required in many milling and turning operations.

A simple twodimensional profile milling operation is shown in Figure 6.4 to

illustrate continuous path control. When continuous path control is utilized to

move the tool parallel to only one of the major axes of the machine tool

worktable, this is called straightcut NC.

When continuous path control is used for simultaneous control of two or more

axes in machining operations, the term contouring

is used.

Interpolation

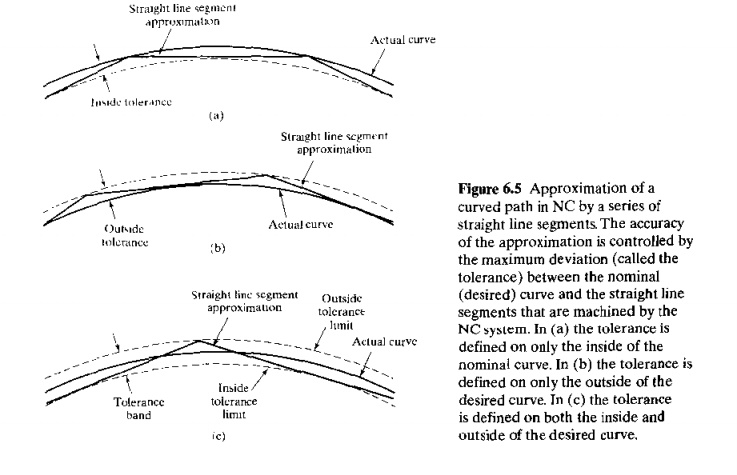

Methods. One of the important aspects of contouring IS inrerpollJlion. The paths

that a contouringtype NC system is required to generate often consist of circular arcs and other smooth

nonlinear shapes. Some of these shapes can be defined mathematically by relatively simple geometric

formulas (e.g., the equation for a circle is Xl + i = R2•where R = the radius of the circle and the

center of the circle is at the origin), whereas others cannot be mathematically

defined except by

approximation. In any case, a fundamental problem in generating these shapes

using NC equipment is that they are continuous, whereas NC is digital. To cut

along a circular path, the circle must be divided into a series of straight

line segments that approximate the curve. The tool is commanded to machine each

line segment in succession so that the machined surface closely matches the

desired shape. The maximum error between the nominal (desired) surface and the

actual (machined) surface can be controlled by the lengths of the individual

line segments, as explained in Figure 6.5.

If the

programmer were required to specify the endpoints for each of the line

segments, the programming task would be extremely arduous and fraught with

errors.Atso, the part program would be extremely long because of the large

number of points. To ease the burden, interpolation routines have been

developed that calculate the intermediate points to be followed by the cutter

to generate a particular mathematically defined or approximated path.

A number

of interpolation methods are available to deal with the various problems

encountered in generating a smooth continuous path in contouring. They include:

(1) linear interpolation, (2) circular interpolation, (3) helical

interpolation, (4) parabolic interpolation, and (5) cubic interpolation. Each

of these procedures, briefly described in Table 6.1, permits the programmer to

generate machine instructions for linear or curvilinear paths using relatively

few input parameters. The interpolation module in the MCU performs the

calculations and directs the tool along the path. In CNC systems, the

interpolator is generally accomplished by software. Linear and circular

interpolators are almost always included in modem CNe systems, whereas helical

interpolation is a common option. Parabolic and cubic interpolations are less

common; they are only needed by machine shops that must produce complex surface

contours.

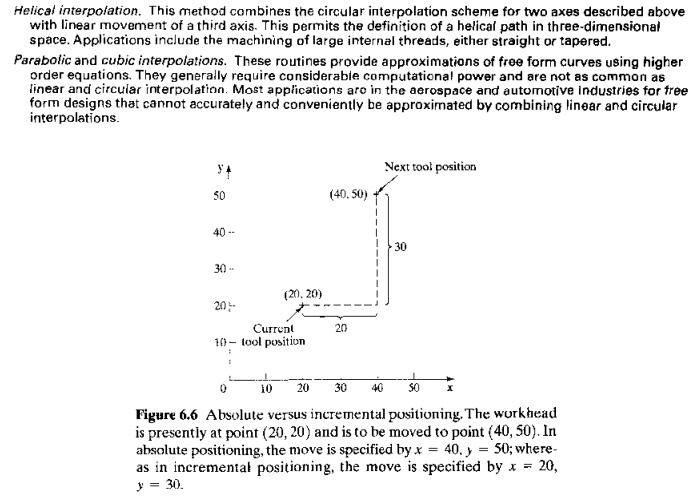

Absolute

Versus Incremental Positioning. Another aspect of motion control

is

concerned

with whether positions are defined relative to the origin of the coordinate

system

Figure 6.5 Approximation of a curved path in NC by a series of straight line segments. The accuracy of the approximation is controlled by the maximum deviation (called the tolerance) between the nominal (desired) curve and the straight line segments that are machined by the NC system. In (a) the tolerance is defined on only the inside of the nominal curve. In (b) the tolerance is defined on only the outside of the desired curve. In (c) the tolerance is defined on both the inside and outside of the desired curve.

Linear

interpolation. This is the

most basic and is used when a straight line path is to be generated in continuous path NC. Twoaxis and

threeaxis linear interpolation routines are sometimes distinguished in

practice, but conceptually they are th ••""me. The programmar

specifies thc beginning point and end point of the straight line and the feed

rate to be used along the straight line. The interpolator computes the feed

rates for each of the two (or three) axes to achieve the specified feed rate.

Circular

interpolation. This method

permits programming of a circular arc by specifying the following parameters: (1) the coorotnetes of the

starting point, (21 the coordinates of the endpoint, (31 either the center or

radius of the arc, and (4) the direction of the cutter along the arc.

The genarated tool path consists of a series of small straight nne segments

(see Figure 6.5) calculated by the interpolation module. The cutter is directed

to move along each line segment onebyone to generate the smooth circular path.

A limitation of circular interpolation is that the plane in which the circular

arc exists must be a plane defined by two axes

of the NC svstern :« y, x Z, or y Z)'

or relative to the previous location of the tool. The two cases are called absolute position ing and incremental positioning. In absolute positioning, the workhead locations are always defined with respect to the origin of the axis system. In incremental positioning, the next workhead position is defined relative to the present location. The difference is illustrated in Figure 6.6.

COMPUTER

NUMERICAL CONTROL

Since the

introduction of NC in 1952, there have been dramatic advances in digital

computer technology. The physical size and cost of 11digital computer have been

significantly reduced at the same time that its computational capabilities have

been substantially increased. It was logical for the makers of NC equipment to

incorporate these advances in computer technology into their products, starting

first with large mainframe computers in the 1960s, followed hy minicomputers in

the 1970s,and microcomputers in the 1980s (Historical Note 6.2). Today, NC

means computer numerical control. Computer

numerical control (CNC) is defined as an NC system whose MeV is based

on a dedicated microcomputer rather

than on a hardwired controller.

Historical Note 6.2 Digital computers for NC

I'he development of NC has relied heavily on advances in digital computer technology. As computers evolved and their performance improved, producers of NC machines were quick to adopt the latest generation of com pUler technology, The first application of the digital computer for NC was 10 perform part programming. In 1956.MIT demonstrated the feasibility of a computeraided part programming system using its Whirlwind I computer (an early digital computer prototype developed at MIT).

Features of CNC

Computer

NC systems include additional features beyond what is feasible with

conventional hardwired NC. These features, many of which are standard on most

CNC MCVs whereas

others are optional, include rhc following'

Storage

of more than one part program. With improvements in computer

storage technology. newer CNC controllers have sufficient

capacity to store multiple programs. Controller manufacturers generally offer

one or more memory expansions as optionstothcMCU.

Variomform.l

of program input. Whereas conventional (hardwired) MCVs are limited

to punched tape as the input medium for entering part programs. CNC controllers

generally possess multiple data entry capabilities, such as punched tape (if

the machine shop still uses punched tape), magnetic tape. floppy diskette.

RS232 communications with external computers, and manual data input (operator

entry of program).

Program editi'll{ at the machine tool. CNC

permits a part program to be edited while

it resides in the MCV computer memory. Hence, the

process of testing and correcting a program can be done entirely at the machine

sire, rather than returning to the programming office to,correct t~e tape. In

addi:ion to part ~tograrn corrections.editing also permits optimizing cuumg

conditions m the machining cycle. After correcting and optimizing the program.

the revised version can be stored on punched tape or other media for future

usc.

Fixed

cycles and programming subroutines. The increased memory capacity and

the ability III I'lOgrmlllhe control cornpurer

provide the opportunity 10store frequently

used

machining cycles as mucros that can

be called by the part program. Instead of writing the full instructions for the

particular cycle into every program, a call statement is included in the part

program to indicate that the macro cycle should be executed. These cycles often

require that certain parameters be defined; for example. a bolt hole circle, in

which the diameter ot the bolt circle, the spacing of the bolt holes, and other

parameters must be specified.

Interpolation.

Some of

the interpolation schemes described in Table 6.1 are normally executed only on a CNC system because

of the computational requirements. Linear and circular interpolation arc

sometimes hardwired into the control unit, but helical, parabolic, and cubic

interpolations are usually executed in a stored program algorithm.

Positioning

features for setup. Setting up the machine tool for a givcn work part

involves installing and aligning a fixture on the machine tool table. This must

be accomplished so that the machine axes are estahlished with respect to the

workpart, The alignment task can be facilitated using certain features made

possible by software options in a CNC system. Position set is one of these features. With position set , the

operator is not required to locate the fixture on the machine table with

extreme accuracy. Instead, the machine tool axes are referenced to the location

of the fixture by using a target point or set of target points on the work or

fixture.

Cutter

length and size compensation. In older style controls, cutter

dimensions had 10 be set very

precisely to agree with the tool path defined in the part program. Alternative

methods for ensuring accurate tool path definition have been incorporated into

CNC controls. One method involves manually entering the actual 1001dimensions

into the MCU. These actual dimensions may differ from those originally

programmed Compensations arc then automatically made in the computed tool path.

Another method involves use of a toollcngth sensor built into the machine. In

this technique. the cutter is mounted in the spindle and the sensor measures

its length. This measured value is then used to correct the programmed tool

path.

Acceleration

and deceleration calculations, This feature is applicable when

the cutter moves at high feed rates.

It is designed to avoid tool marks on the work surface that would be generated

due to machine tool dynamics when the cutter path changes abruptly. Instead,

the feed rate is smoothly decelerated in anticipation of a tool path change and

then accelerated back up to the programmed feed rate after the direction

change.

Communications

interface. With the trend toward interfacing and networking in

plants today, most modem CNC

con/rollers are equipped with a standard RS232 or other communications

interface to allow the machine to be linked to other computers and

computerdriven devices. This is useful for various applications, such as: (1)

downloading part programs from a central data file as in distributed NC; (2)

collecting operational data such as workpiece counts, cycle times, and machine

utilization; and

interfacing with peripheral equipment.

such as robots that load and

unload parts.

Diagnostics. Many modern CNC systems possess

an online diagnostics capability that

monitors certain aspects of the machine tool to detect malfunctions or signs of

impending malfunctions or to diagnose system breakdowns. Some of the common

features of a CNC diagnostics system are listed in Table 6.2

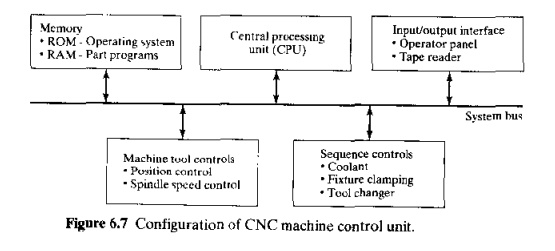

The Machine Control Unit for CNC

The MCU is the hardware that distinguishes CNC

from conventional NC. The general configuration of the MCV in a CNC system is

illustrated in Figure 6.7. The MCV

consists of the following components and subsystems: (I) central processing

unit, (2) momery,

(3) lIO interface. (4) controls for machine tool

axes and spindle speed. and (5) sequence controls for other machine tool

functions. These subsystems are interconnected by means of a system bus. as

indicated in the figure,

Centra!

Processing Unit. The central processing unit (CPU) i~the brain of the Mev. It

manages the other components in the Mel! based on software contained in

main

memory.Thc

CPU can be divided into three sections: (1) control section, (2)

arithmeticlogic unit, and (3) immediate access memory. The control section retrieves commands and data from memory and

generates signals 10 activate other components in the Meu. In short, it sequences.

coordinates. and regulates all of the activities of the Mrl J computer. The arithmeuciogtc unit (ALU) consists of

the circuitry to perform various calculations (addition, subtraction, multiplication), counting. and logical functions

required by software residing in memory. The immediate access memory provides a temporary storage for data being

processed by the CPu. It is connected to main memory by means of the system

data bus.

Memory.

The

immediate (lCCCSS memory in the CPU is not intended

for storing CNC software, A much greater storage capacity is required for the

various programs and data needed to operate the CNC system. As with most other

computer systems, CNC memory can be divided into two categories: (I) main

memory and (2) secondary memory. Main

memory

(also

known as primary storaf;e) consists of RO\1 (readonly memory) and RAM (random

access memory) devices. Operating system software and machine interface

programs (Section 6.2.3) are generally stored in ROM. These programs are

usually installed by the manufacturer of the MCU. Numerical control part

programs are stored in RAM devices. Current programs in RAM can he erased and

replaced by new programs as jobs are changed.

Highcapacity

secondary memory (also called auxiliary storage or secondary storage) devices are used to

store large programs and data files, which are transferred to main memory as

needed. Common among the secondary memory devices are floppy diskettes and hard

disks. Floppy diskettes are portable and have replaced much of the punched

paper tape traditionally used 10 store part programs. Hard disks are

highcapacity storage devices that are permanently installed in the CNC machine

control unit. CNC secondary memory is used to store part programs, macros, and

other software.

Input/Output

Interface. The IIO interface provides communication

between the various components of the CNC system, other computer systems. and the

machine operator. As its name suggests, the 110 interface transmits and receives

data and signals to and [rom external devices, several of which are indicated

in Figure 6.7. The opera/or control panel is the

basic interface by which the machine operator communicates to the CNC system.

This is used to enter commands relating to part program editing, MeU operating mode (e.g .. program

control vs. manual control),speeds and feeds, cutrtng fluid pump onloff, and

similar functions. Either an alphanumeric keypad or keyboard is usuallv

included in the operator control panel. The 110interface

also includes a display (CRT or LED) for corn~unication o.fdata and

information from the MCV to the machine operator. The

display IS used to indicate current status of the program as it is being

executed and to warn the operator of any malfunctions in the CNC system.

Also included in the 110 interrace are one or more means of entering the part program into storage. As indicated previously, NC part programs are stored in a variety of ways, including punched tape. magnetic tape, and floppy disks. Programs can also be entered manually by the machine operator or stored at a central computer site and transmitted via loea! area nl'T~'nrk (LAN) to the CNCsystem',Whichevcr mcans.isemployed by the plant, a suitable device must be included in the J/O interface 10 allow input of the program into MCU memory.

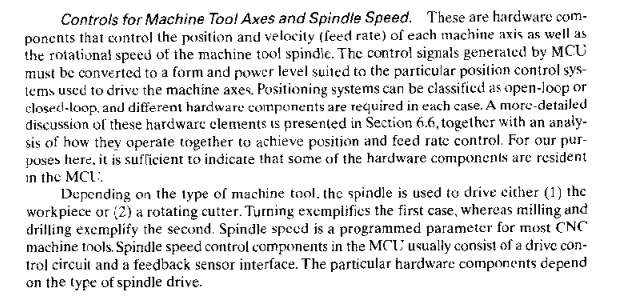

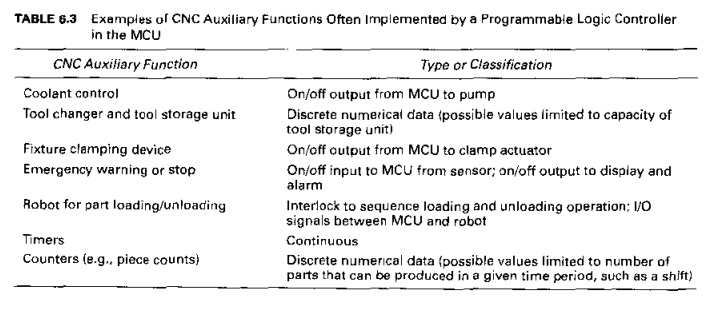

Sequence

Controls for Other Machine Tool Functions. In addition to control of table

position. feed rate. and spindle speed, several additional functions arc

accomplished under pan program control.These auxiliary functions arc generally

on/off (binary] actuations. interlocks. and discrete numerical data. A sampling

of these functions is presented in Table 0.3. To avoid overloading the CPU, a

prograrnrnable logic controller (Chapter H) is sometimes used to manage the 110 interface for these auxiliary

functions

Personal

Computers and the MCV. In growing numbers, personal computers (PCs) are

being used in the factory to implement process control (Section 4.4.6), and CNC

is no exception. Tho basic configurations are being applied [14J: (1) the PC is

used as a separate frontend interface for the MCU, and (2) the PC contains the

motion control board and other hardware required to operate the machine tool.

In the second case, the CNC control board fits into a standard slot of the P'C.

In either configuration, the advantage of using a PC for CNC is its flexibility

to execute a variety of user software in addition

to and

concurrently with controlling the machine tool operation. The user software

might include programs for shopflour control. statistical process control,

solid modeling,cutting tool management, and other computeraided manufacturing

software. Other benefits include improved case of use compared with

conventional CNC and ease of networking the PCs, Possible disadvantages include

(1) lost time to retrofit the PC for OK. particularly when installing the rNr motion controls inside the PC

and (2) current limitations in applications requinng complex fiveaxis control

of the machine toolfor these application>, traditional CNC is still more

efficient. II should he mentioned that advances in the technology of PCbased CNC

are likely to reduce these disadvantages over time. Companies are demanding

open architecture in CNC products, which permits components from different

vendors to be used in the same system [7J

CNC Software

The

computer in CNC operates by means of software. There are three types of

software programs used in CNC systems: (I) operating system software, (2)

machine interface software, and (3) application software.

The

principal function of the operating

system software is to interpret the NC part pro

grams and

generate the corresponding control signals to drive the machine tool axes. It

is installed by the controller rnanuracturer and is stored in ROM in the MCU.

The operating

system

software consists of the following: (1) an editor,

which permits the machine operator to input and edit NC part programs and

perform other file management functions: (2) a control program, which decodes the part program instructions,

performs interpolation and acceleration/deceleration

calculations, and accomplishes other

related functions to produce the coordinate control signals for each axis.and

(3) an executive program, which

manages the execution of the CNC software as well as the 1/0 operations of the Mev. The operating system software

also includes the diagnostics routines that are available in the CNC svstem

(Table 6.2).

The machine interface software is used to

operate the communication link between the CPU and the machine tool to

accomplish the CNC auxiliary functions (Table 6.3).As previously indicated, the

I/O signals associated with the auxiliary functions arc sometimes im

plemented

by means of a programmable logic controller interfaced to the MCU,and so the

machine interface software is often written in tbe form of ladder logic

diagrams (Section 8.2).

Finally,

the application software consists of

the NC part programs that are written for machining (or other) applications in

the user's plant. We postpone the topic of part programming to Section 6.5.

Related Topics