Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Numerical Control

Numerical Control Coding System

NC PART PROGRAMMING

NC part

programming consists of planning and documenting the sequence of processing

steps 10 be performed on an NC machine. The part programmer must have a

knowledge of machining (or other processing technology for which the NC machine

is designed) as well as geometry and trigonometry. The documentation portion of

par! programming involves the input medium used to transmit the program of

instructions to the NC machine control unit (MCU). The traditional input medium

dating back to the first NC machines in the 1950s is linch wide punched rape,

More recently the use of magnetic tape and floppy disks have been growing in

popularity as storage technologies for NC Th ••,

advantage. of these input media is their much higher data density.

Part programming can he accomplished using a variety of procedures ranging from highly manual to highly automated methods. The methods are: (1) manual part programming, (2) computerassisted part programming, (3) part programming using CAD/CAM. and (4) manual data input. These part programming techniques are described in this section. Let us begin our presentation by explaining the NC coding system used to convoy the part program to the machine tool

NC Coding System

The

program of instructions is communicated to the machine tool using a coding

system based on binary numbers. This NC coding system is the low-level machine language

that can be understood by the MCU. when higher

level languages are used. such as A[Yf (Section 6.5.4), the statements in the

program are converted to this basic code. In the present section, we discuss

how instructions are written in this NC code to control the relative positions

of the tool and workpiece and to accomplish

the other functions of the machine tool.

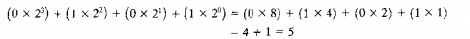

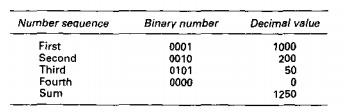

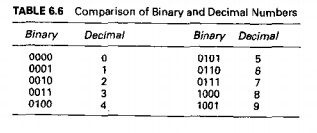

Conversion

of the 10 digits in the decimal number system into binary numbers is shown in

Table 6,6. Four binary digits are required to represent the ten singledigit

numbers in decimal. Of course, the numerical data required in NC includes large

decimal values; for example, the coordinate position .r = 1250 rnrn. To encode the decimal

value 1250 in the binary number system requires a total of 11 digits:

10011100010. Another problem with the binary number system is the coding of

decimal fractions, for example, feed = 0.085

mm/rev.

To deal

with these problems in NC, a combination of the binary and decimal number

systems has been adopted, called the binarycoded

decimal (BCD) system. In this coding scheme, each of the ten digits (09) in

the decimal system is coded as a fourdigit binary number, and these binary

numbers are added in sequence as in the decimal number system. For example, the

decimal value 1250 would be coded in BCD as follows:

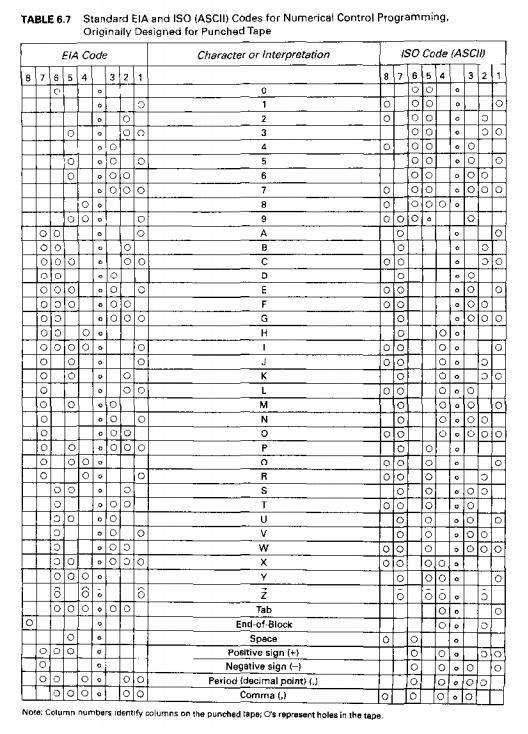

EIA and

ISO Coding Standards. In addition to numerical values, the NC coding system

must also provide for alphabetical characters and other symbols. Eight binary

dig. its are used to represent all of the characters required for NC part

programming. There are two standard coding systems currently used in NC: (1)

the Electronics Industry Association (EIA) and (2) the International Standards

Organization (ISO). The Electronics Industry Association system is known as EIA

RS244R The ISO code was originally developed as the American Standard Code for

Information Interchange (ASCII) and has been adopted by ISO as its NC standard.

The complete listings of EIA and ISO (ASCII) codes for NC are shown in Table

6.7. Many NC controllers are capable of reading either code,

Both EIA

and ISO coding schemes were developed when punched tape was the predominant

medium fur storing NC part programs. Although punched tape has been largely

superseded by more modern media. it is still widely used in industry. if only

for backup storage. To ensure the correctness of the punched tape. the eight

binary digits in the EIA and ISO codes include a paru» check. Here's how the parity check work, explained here

ber of

holes across the width of the tape. Whenever the particular number or symbol

being punched requires an even number of holes. an extra hole is punched in

column 5, hence making the lotal an odd number. For example, the decimal

numberS is coded by means of holes in columns 1 and 3. Since this is an even

number of holes, a parity hole would be: added. The decimal 7 requires an odd

number of holes (in columns 1, 2, and 3),so no parity hole is needed. The

parity check helps 10 ensure that the tape punch mechanism has perforated a

complete hole in all required positions. If the tape reader counts an even

number of holes. then a signal is issued that a parity error has occurred.

The

difference between the EIA and ISO systems is that the parity check in the ISO

code i~ an even number of holes, called an even

parity. The EIA system uses an odd

parity.Aho. whereas the parity hole is in the fifthdigit position in the

'EIA coding system, it is in the

eighth position in the ISO system. These differences can be seen in Table 6.7

How tnstructions Are Formed. A binary digit is called a bit. In punched tape, the values 0 or 1 are represented by the

absence or presence of a hole in a certain row and column position (rows run

across the tapecolumns run lengthwise along the tape). Out of one row of bits a

character is formed. A character is a

combination of bits representing a numericaldigit (09), an alphabetical letter

(AZ),or a symbol (Table 6.7). Out ofa sequence of characters, a word is formed.

A wont specifies a detail about the

operation, such as .rposition, ypositlon, feed rate, or spindle speed. Out of a

collection of words, a block is formed. A block

is one complete NC instruction. It specifies the destination for the move, the

speed and feed of the cutting operation. and other commands that determine

explicitlywhat the machine tool will do. For example, an instruction block for

a twoaxis NC milling machine would likely include the x and vcoordinates to which the machine table should be moved, the

type of motion to be performed (linear or circular interpolation), the rota

tional

speed of the milling cutler, and the feed rate at which the milling operation

should be performed. Imtn.lction blocks arc separated by an endofblock (LOB)

symbol (a hole

in column

8 in the EIA standard or holes in columns 2 and 4 in the ISO standard. as in

Table 6.7).

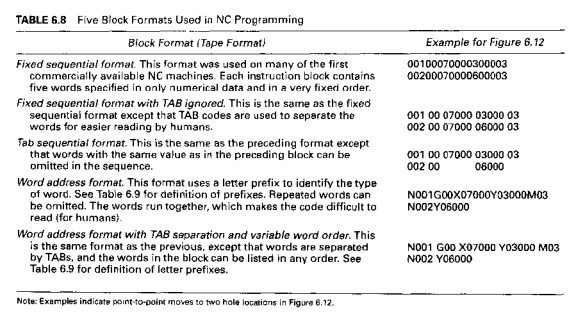

The

essential information in a part program is conveyed to the MCU by means of

words that specify coordinates, feeds and speeds, tooling, and other commands

necessary to operate the machine tool. Given the variety of machine tool types

and the many different companies that build NC machine tools and MCUs, it is no

surprise that several different formats have been developed over the years to

specify words within an instruction block. These are often referred to as tape

formats, because they were developed for punched tapes, More generally, they are

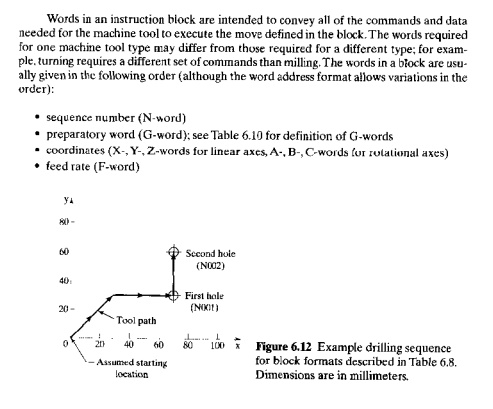

known as block formats. At least five

block formats have been developed [8]; these are briefly described in Table

6.8, with two lines of code for the drilling sequence shown in Figure 6.12

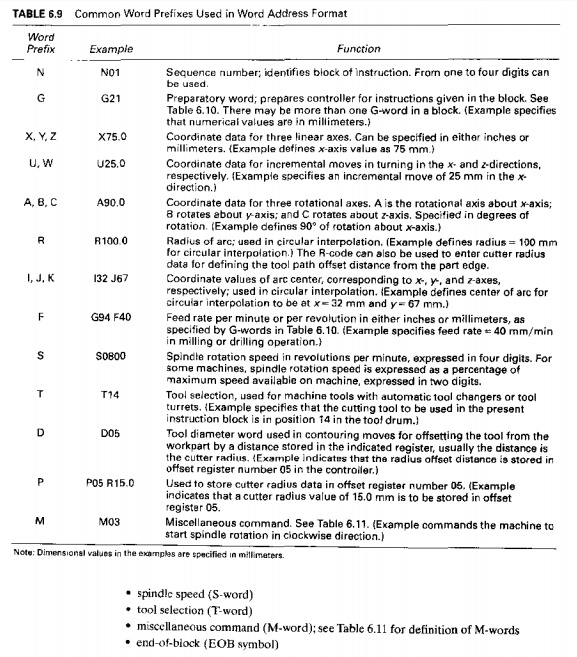

The word

address format with TAB separation and variable word order has been

standardized by EIA as RS·274. It is the block format used on all modern

controllers and is the format we will discuss hcre.It is usually referred to

simply as the word address format even though it has been enhanced by tab

separation and variable word order. Com. man letter prefixes used in the word

address format are defined in Table 6.9.

Words in

an instruction block are intended to convey all of the commands and data needed

for the machine tool to execute the move defined in the block. The words

required for one machine tool type may differ from those required for a

different type; for example. turning requires a different set of commands than

milling. The words in a block are usually given in the following order

(although the word address format allows variations in the order):

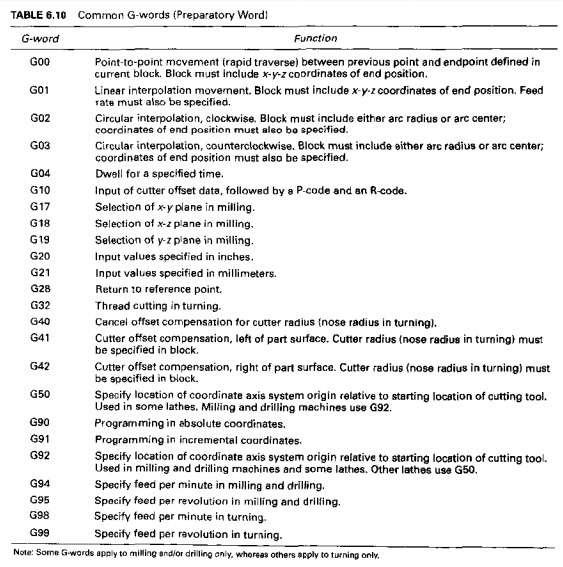

G-words and Mwords require some elaboration. Gwords are

called preparatory words. They

consist of two numerical digits (following the "G" prefix in the word

address for mat) that prepare the MeU for the

instructions and data contained in the block. For example, G02 prepares the

controller for clockwise circular interpolation, so that the subsequent data in

the block can be properly interpreted for this type of move. In some cases,

more than one Gword is needed to prepare the MeU for the move. Most of the common Gwords are presented in Thble

6.10.While Gwords have been standardized in the machine tool industrv, there

arc sometimes deviations for particular machines. For instance, there are several

differences between milling and turning type machines; these are identified in

Table 6.10.

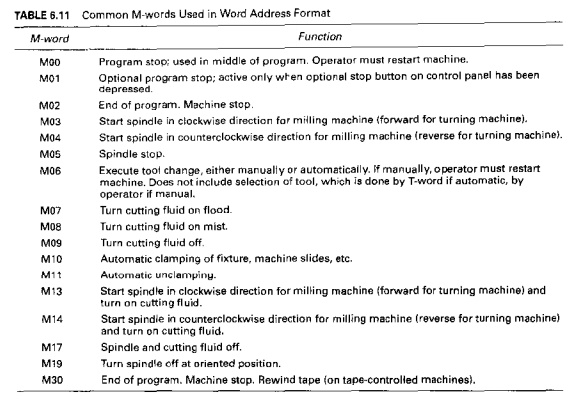

M-words

are used to specify miscellaneous or auxiliary functions that an: available on

the machine tool. Examples include starting the spindle rotation, stopping the

spindle for a tool change, and turning the cutting fluid on or off. Of course,

the particular machine tool must possess the function that is being called.

Many of the common M-words are explained in Table 6.11. Miscellaneous commands

are normally placed at the end of the block.

Related Topics